Company Profile

Womic Steel Group is the leading professional steel pipe manufacturer in China with over 20 years experience, which is also the top supplier in manufacturing and exporting of welded and seamless carbon steel pipes, stainless steel pipes, pipe fittings, galvanized steel pipes, steel hollow sections, boiler steel tubes, precision steel tubes, EPC company construction used steel materials, OEM steel pipe fittings and spools.

Backed by a complete set of testing facilities, our company strictly abides by the ISO 9001 quality management system and has been certified by numerous authoritative TPI organizations, such as SGS, BV, TUV, ABS, LR, GL, DNV, CCS, RINA, and RS.

Seamless Steel Pipes

Womic Steel Seamless Steel Pipe Overview

Womic Steel specializes in manufacturing high-quality seamless steel pipes using advanced production technology and strict quality control to meet international standards.

Production Capacity: Over 10,000 tons per month

Size Range: OD 1/4" - 36"

Wall Thickness: SCH10 - XXS

Standards & Materials:

ASTM: A106 (Gr.A, Gr.B, Gr.C), A53 (Gr.A, Gr.B), API 5L (Gr.B, X42-X80)

EN: 10210 (S235JRH, S275J2H, S355J2H), 10216-1 (P195TR1, P235TR2, P265TR2), 10305-1 (E215, E235, E355), 10305-4 (E235, E355)

DIN: 1629 (St37.0, St44.0, St52.0), 2391 (St35, St45, St52)

Applications: Structural engineering, machining, fluid transportation, oil & gas, hydraulic and pneumatic systems, automotive, and boiler industries.

Custom processing options include hot-rolled, cold-drawn, heat-expanded, and anti-corrosion coatings.

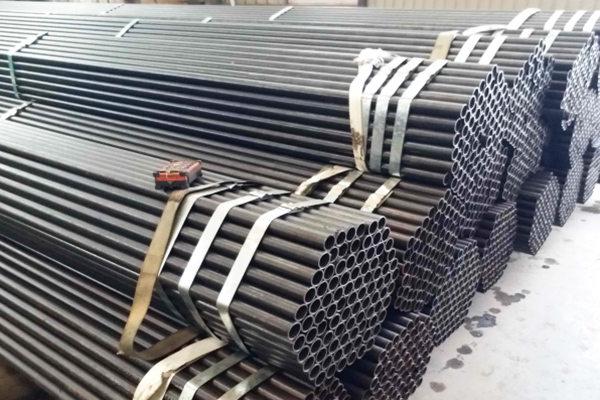

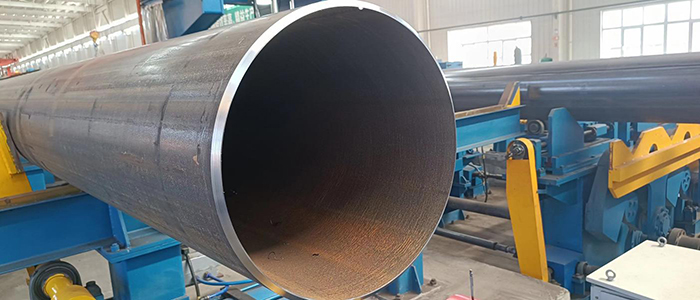

Welded Steel Pipes

Womic Steel Welded Steel Pipe Overview

Womic Steel specializes in manufacturing high-quality welded steel pipes, including ERW and LSAW types, using advanced production technology and strict quality control to meet international standards.

Production Capacity: Over 15,000 tons per month

Size Range: ERW: OD 1/4" - 24", LSAW: OD 14" - 92", Wall Thickness: SCH10 - XXS

Standards & Materials:

ASTM: A53 (Gr.A, Gr.B), A252, A500, API 5L (Gr.B, X42-X80), A690, A671 (Gr.60, Gr.65, Gr.70)

EN: 10219 (S235JRH, S275J2H, S355J2H), 10217-1 (P195TR1, P235TR2, P265TR2)

DIN: 2458 (St37.2, St44.2, St52.3)

Shipbuilding Standards: Pipes conforming to ABS, DNV, LR, and BV standards for marine and offshore applications, including materials like A36, EQ36, EH36, and FH36

Applications: Structural construction, fluid transportation, oil & gas pipelines, piling, mechanical engineering, pressure applications, and marine/offshore use, including shipbuilding and offshore platforms.

Custom processing options include galvanized, epoxy-coated, 3LPE/3LPP, beveled ends, and threading & coupling.

Cold-drawn Precision Tubes

Womic Steel Precision Steel Pipe Overview

Womic Steel specializes in producing high-precision steel pipes, both seamless and welded, manufactured with strict tolerances to ensure superior quality and performance. Our pipes are designed for various industries, including hydraulic cylinders, pneumatic systems, mechanical engineering, automotive, and oil & gas applications. Our high precision steel tubes products are also frequently used in applications such as conveyors, rollers, idlers, honed cylinders, textile mills, and axles and bushes.

Production Capacity: Over 5,000 tons per month

Size Range: OD 1/4" - 14", Wall Thickness: SCH10 - SCH160, with precision tolerances of ±0.1 mm for outer diameter and wall thickness, ovality ≤0.1 mm, and straightness ≤0.5 mm per meter.

Standards & Materials:

We comply with various international standards such as ASTM A519 (Grade 1020, 1045, 4130, 4140), A213 (T5, T9, T11, T22, T91), EN 10305-1 (E215, E235, E355), DIN 2391 (St35, St45, St52), DIN 1629 (St37.0, St44.0, St52.0), and SANS 657 (for precision steel tubes). Common materials include carbon steels (1020, 1045, 4130), alloy steels (4140, 4340), and stainless steels (304, 316).

Our custom processing options include cold-drawn, heat-treated, polished, and anti-corrosion coatings to meet specific customer requirements.

Alloy Steel Pipes

Womic Steel specializes in manufacturing high-quality alloy steel pipes, including seamless and welded types, using advanced production technology and strict quality control to meet international standards.

Production Capacity: Over 6,000 tons per month

Size Range: Seamless: OD 1/4" - 24", Welded: OD 1/2" - 80"

Wall Thickness: SCH10 - SCH160

Standards & Materials:

ASTM: A335 (P1, P5, P9, P11, P22, P91), A213 (T5, T9, T11, T22, T91), A199 (T5, T9, T11, T22)

EN: 10216-2 (10CrMo5-5, 13CrMo4-5, 16Mo3, 25CrMo4, 30CrMo), 10217-2 (P195GH, P235GH, P265GH), ASTM A333 Grade1-6, ASTM A387, ASTM A691, ASTM A530....

DIN: 17175 (St35.8, 15Mo3, 13CrMo44, 10CrMo910)

Applications: Power plants, pressure vessels, boilers, heat exchangers, oil & gas, petrochemical industries, and high-temperature applications.

Custom processing options include normalized, quenched & tempered, annealed, heat-treated, and anti-corrosion coatings.

Stainless Steel Pipes

Womic Steel Stainless Steel Pipe Overview

Womic Steel specializes in manufacturing high-quality stainless steel pipes, including seamless and welded types, using advanced production technology and strict quality control to meet international standards.

Production Capacity: Over 8,000 tons per month

Size Range:

Seamless: OD 1/4" - 24"

Welded: OD 1/2" - 80"

Wall Thickness: SCH10 - SCH160

Standards & Materials:

ASTM: A312 (304, 304L, 316, 316L, 321, 347), A213 (TP304, TP316, TP321), A269 (304, 316), A358 (Class 1-5) , ASTM 813/DIN/GB/JIS/AISI etc…

Duplex Steel: ASTM A790 (F51, F53), ASTM A928 (S31803, S32750)

EN: 10216-5 (1.4301, 1.4306, 1.4404, 1.4571), 10217-7 (1.4301, 1.4404, 1.4541)

DIN: 17456, 17457, 17458 (X5CrNi18-10, X2CrNiMo17-12-2, X6CrNiTi18-10)

Applications: Chemical processing, food and beverage industry, pharmaceuticals, heat exchangers, fluid and gas transportation, construction, and marine applications.

Custom processing options include polished, pickled, annealed, heat-treated.

Pipe Fittings

Womic Steel offers a wide range of high-quality pipe fittings and flanges, designed for industries such as oil & gas, petrochemical, power generation, and construction. Our products are manufactured using premium materials and meet international standards for reliability, durability, and performance.

Pipe Fittings & Flanges Types:

Elbows (90°, 45°, 180°), Tees (Equal & Reducing), Reducers (Concentric & Eccentric), Caps, Flanges (Slip-on, Weld Neck, Blind, Threaded, Socket Weld, Lap Joint, etc.)

Standards & Materials:

Our pipe fittings and flanges comply with international standards including ASTM A105 (carbon steel), A182 (stainless steel), A350 (low-temperature service), A694 (high-pressure service), EN 1092-1, 10241, DIN 2573, 2615, API 6A, NACE MR0175 (for sulfide stress cracking resistance), JIS B2220, and GB/T 12459, 12462. Common materials include carbon steel (A105, A350, A694), stainless steel (A182, 304, 316), alloy steel and low-temperature steel (A182 F5, F11, A350 LF2), and nickel alloys like Inconel and Monel.

Applications:

These products are used in fluid transportation, pressure applications, and structural purposes in industries like oil & gas, petrochemical, power plants, and more. Custom coatings such as anti-corrosion, galvanizing, and polishing are available to meet specific industry requirements.

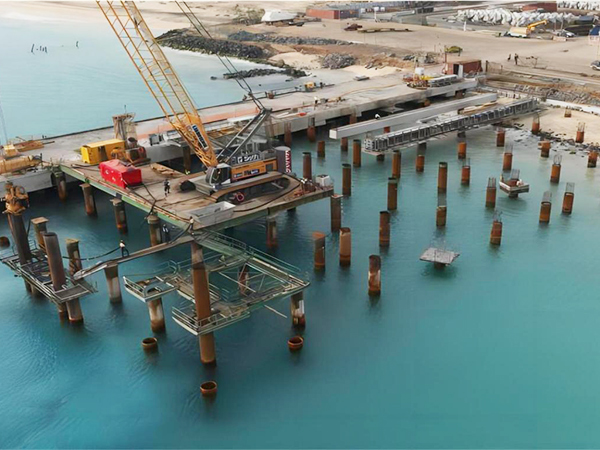

Project Application

The steel pipe products provided by Womic Steel have been widely used in various engineering projects, including oil and gas extraction, water transportation, urban pipeline network construction, offshore and onshore platform construction, mining industry, chemical industry, and power plant pipeline construction. The company's partners span Southeast Asia, the Middle East, Europe, Africa, South America, Oceania, and over 80 countries and regions.

Our Strength

In addition, Womic Steel provides a range of steel pipe products and services to the world's top 500 petroleum and gas companies, as well as EPC contractors, such as BHP, TOTAL, Equinor, Valero, BP, PEMEX, Petrofac, and so on.

Womic Steel adheres to the principle of "Customer first, Quality Best" and is confident in supplying customers with high-quality products at competitive prices. Womic Steel will always be your most professional and reliable business partner. Womic Steel are committed to providing one-stop service to our customers all over the world.

Main Products Range

Coatings service: Hot dipped galvanized, FBE, 2PE, 3PE, 2PP, 3PP, Epoxy...

ERW Steel Pipe

OD 1/2 – 26 inch (21.3-660mm)

SSAW / LSAW Steel Pipe

OD 8 – 160 inch (219.1-4064mm)

Seamless Steel Pipe

OD 1/8 – 36 inch (10.3-914.4mm)

Boiler Steel Tubes

Stainless Steel Pipes & Fittings

Carbon Steel Fittings / Flanges / Elbows / Tee / Reducer / Spools

What We Do

Pipes & Accessories Stocking

● Carbon Steel Pipe

● Oilfield Tubular Goods

● Coated Steel Pipe

● Stainless Steel Pipe

● Pipe Fittings

● Value Added Products

Projects Serving

● Oil&Gas&Water

● Cilvil Construction

● Mining

● Chemical

● Power Generation

● Offshore & Onshore

Services & Customizing

● Cutting

● Painting

● Threading

● Slotting

● Grooving

● Spigot & Socket Push-Fit Joint

Why Choose Us

Womic Steel Group well experienced in steel pipe production and exporting, also well cooperated with some well-known EPC contractors, importers, traders and stockiest for many years. The good quality, competitive price and flexible payment term always makes our customers feel satisfied, and widely recognized & trusted by end users and always gets positive feedback and praises from our customers.

The steel tubes/pipes & fittings we produced are widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Enterprise Advantages

Professional Production Services

After more than twenty years of dedicated service, the company has a deep understanding of the production and export of steel pipes. This wealth of knowledge enables them to expertly cater to the needs and requirements of clients across the globe, ensuring unparalleled client satisfaction.

Support Product Customization

With its expertise in producing custom steel pipe fittings, Womic Steel Group has become the first choice for various industries looking for custom solutions to meet their specific requirements.

Widely Used Products

Welded pipes are made by joining the edges of steel sheets or coils while seamless pipes are produced without any welding. This versatility in production capabilities enables the company to cater to a wide range of applications, adapting to various industries such as construction, oil and gas, and automotive.

Professional Service Team

In addition to technical competence, Womic Steel Group places great emphasis on customer service and satisfaction. The company has a professional and experienced customer support team to provide personalized assistance from the initial inquiry to after-sales support.