Product Description

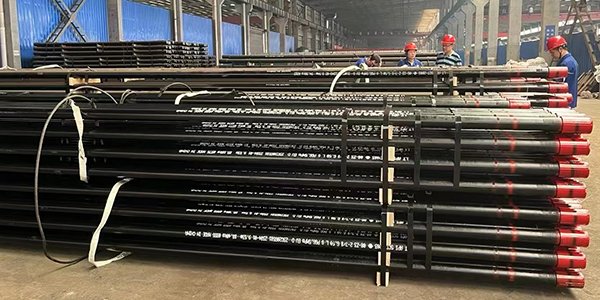

Drill pipe used to connect the surface equipment of the drilling rig to the grinding or drilling equipment, it is the steel pipe with thread ends, also making the connection of the bottom hole equipment of the drilling. Drill pipe normally divided into kelly, drill pipe and heavy drill pipe. Steel Drill Pipes comes in a variety of sizes, strengths, and wall thicknesses, but is typically 27 to 32 feet in length (Range 2). Longer lengths, up to 45 feet, exist (Range 3).

Drill collar is the main section of the lower drill tool, it is worked at the bottom of the drill string. The thickness of the drill collar is larger, and also the greater gravity and rigidity. To improve the tripping work, processing elevator grooves and slip grooves on the outer surface of the inner thread of the drill collar would be a good choice. Spiral drill collars, integral drill collars. and non-magnetic drill collars are the main drill collars in the market.

Specifications

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D : E75, X95, G105, S135 |

| EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454 :STPG 370, STPG 410 |

| JIS G3456 :STPT 370, STPT 410, STPT 480 |

| GB/T 8163 :10#,20#,Q345 |

| GB/T 8162 :10#,20#,35#,45#,Q345 |

Standard & Grade

Drilling Pipes Standard Grades:

API 5DP, API Spec 7-1 E75,X95,G105 ect...

Connection Types: FH,IF,NC,REG

Thread Types: NC26,NC31,NC38,NC40,NC46,NC50,5.1/2FH

Material: Carbon steel/Stainless Steel/Alloy Steel

The drilling pipe should be delivery according to above the connections with standard of API5CT / API Standards.

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection , Tension Test, Dimension Check, Bend Test , Flattening Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test…..

Marking, Painting before delivery.

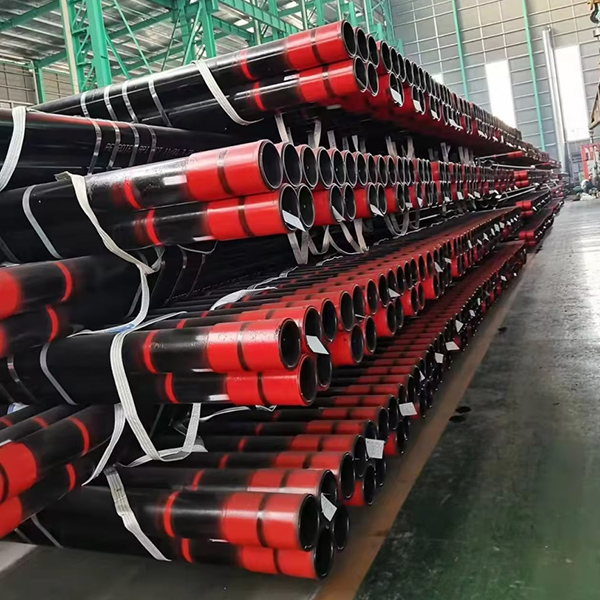

Packing & Shipping

The packaging method for steel pipes involves cleaning, grouping, wrapping, bundling, securing, labeling, palletizing (if necessary), containerization, stowing, sealing, transportation, and unpacking. Different kinds of steel pipes and fittings with different packing methods. This comprehensive process ensures that the steel pipes shipping and arrive at their destination in optimal condition, ready for their intended use.

Usage & Application

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide.

The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...