Product Description

Casing and tubing widely used for oil and gas develop, Casing and tubing are essential components in the oil and gas industry used for the extraction and transportation of hydrocarbons (oil and natural gas) from underground reservoirs to the surface. They play crucial roles in ensuring the safety, integrity, and efficiency of drilling and production operations.

Tubing is a kind of pipeline used to transfer the crude oil and natural gas from the oil layer or gas layer to the ground after the drilling is finished. Tubing can allows the pressure generated during the extraction process. Tubing produced as the same way as casing, but the process called "upsetting" is additionally needed to thicken the tubing pipe.

Casing is used to protect the boreholes that have been dug into the ground for oil. Used same as the drill pipe, oil well casing pipes also allow the axial tension pressure, so high-quality high-strength steel is required. OCTG casings are large diameter pipes that are cemented into the borehole.

Specifications

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

ISO/API Steel Casing list

| Labels a | Outside diameter D mm |

Nominal linear mass b, c T&C kg/m |

Wall thickness t mm |

Type of end-finish | ||||||||

| 1 | 2 | H40 | J55 K55 |

M65 | L80 C95 |

N80 Type 1,Q |

C90 T95 |

P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 |

9.50 10.50 11.60 13.50 15.10 |

114,30 114,30 114,30 114,30 114,30 |

14,14 15,63 17,26 20,09 22,47 |

5,21 5,69 6,35 7,37 8,56 |

PS — — — — |

PS PSB PSLB — — |

PS PSB PLB PLB — |

— — PLB PLB — |

— — PLB PLB — |

— — PLB PLB — |

— — PLB PLB PLB |

— — — — PLB |

| 5 5 5 5 5 5 5 |

11.50 13.00 15.00 18.00 21.40 23.20 24.10 |

127,00 127,00 127,00 127,00 127,00 127,00 127,00 |

17,11 19,35 22,32 26,79 31,85 34,53 35,86 |

5,59 6,43 7,52 9,19 11,10 12,14 12,70 |

— — — — — — — |

PS PSLB PSLBE — — — — |

PS PSLB PLB PLB PLB — — |

— — PLBE PLBE PLB PLB PLB |

— — PLBE PLBE PLB PLB PLB |

— — PLBE PLBE PLB PLB PLB |

— — PLBE PLBE PLB PLB PLB |

— — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 |

14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 |

139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 |

20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 |

6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 |

PS | PS PSLBE PSLBE |

PS PSLB PLB PLB PLB |

— — PLBE PLBE PLBE — — — — — — — |

PLBE PLBE PLBE |

PLBE PLBE PLBE P P P P P P P |

PLBE PLBE PLBE |

— — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 |

20.00 24.00 28.00 32.00 |

168,28 168,28 168,28 168,28 |

29,76 35,72 41,67 47,62 |

7,32 8,94 10,59 12,06 |

PS — — |

PSLB PSLBE — |

PSLB PLB PLB — |

— PLBE PLBE PLBE |

— PLBE PLBE PLBE |

— PLBE PLBE PLBE |

— PLBE PLBE PLBE |

— — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 |

17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 |

177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 |

25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 |

5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 |

PS PS — — — — — — — — — — — |

— PS PSLBE PSLBE — — — — — — — — — |

— PS PLB PLB PLB PLB — — — — — — — |

— — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — |

— — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — |

— — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P |

— — — PLBE PLBE PLBE PLBE PLBE — — — — — |

— — — — — — PLBE PLBE — — — — — |

| See notes at end of table. | ||||||||||||

| Labels a | Outside diameter D mm |

Nominal linear mass b, c T&C kg/m |

Wall thickness t mm |

Type of end-finish | ||||||||

| 1 | 2 | H40 | J55 K55 |

M65 | L80 C95 |

N80 Type 1,Q |

C90 T95 |

P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 |

24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 |

193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 |

35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 |

7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 |

PS | PSLBE | PSLB PLB PLB |

PLBE PLBE PLBE PLBE PLB PLB PLB |

PLBE PLBE PLBE PLBE PLB PLB PLB |

PLBE PLBE PLBE PLBE PLB PLB PLB P P |

PLBE PLBE PLBE PLB PLB PLB |

PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19,685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 |

24.00 28.00 32.00 36.00 40.00 44.00 49.00 |

219,08 219,08 219,08 219,08 219,08 219,08 219,08 |

35,72 41,67 47,62 53,57 59,53 65,48 72,92 |

6,71 7,72 8,94 10,16 11,43 12,70 14,15 |

PS PS — — — — |

PS — PSLBE PSLBE — — — |

PS PS PSLB PSLB PLB — — |

— — — PLBE PLBE PLBE PLBE |

— — — PLBE PLBE PLBE PLBE |

— — — PLBE PLBE PLBE PLBE |

— — — — PLBE PLBE PLBE |

— — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 |

32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 |

244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 |

48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 |

7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 |

PS PS — — — — — — — — — |

— PSLB PSLBE — — — — — — — — |

— PSLB PSLB PLB PLB — — — — — — |

— — PLBE PLBE PLBE PLBE PLB — — — — |

— — PLBE PLBE PLBE PLBE PLB — — — — |

— — PLBE PLBE PLBE PLBE PLB P P P P |

— — — PLBE PLBE PLBE PLB — — — — |

— — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 |

32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 |

273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 |

48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 |

7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 |

PS PS |

PSB PSBE PSBE |

PSB PSB PSB PSB |

PSBE PSBE |

PSBE PSBE |

PSBE PSBE PSBE PSB P P P |

PSBE PSBE PSBE PSB |

PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 |

42.00 47.00 54.00 60.00 65.00 71.00 |

298,45 298,45 298,45 298,45 298,45 298,45 |

62,50 69,94 80,36 89,29 96,73 105,66 |

8,46 9,53 11,05 12,42 13,56 14,78 |

PS — — — |

PSB PSB PSB — — |

PSB PSB PSB — — |

— — PSB P P |

— — PSB P P |

— — PSB P P |

— — PSB P P |

— — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 |

48.00 54.50 61.00 68.00 72.00 |

339,72 339,72 339,72 339,72 339,72 |

71,43 81,10 90,78 101,19 107,15 |

8,38 9,65 10,92 12,19 13,06 |

PS — — — — |

— PSB PSB PSB — |

— PSB PSB PSB — |

— — — PSB PSB |

— — — PSB PSB |

— — — PSB PSB |

— — — PSB PSB |

— — — — PSB |

| See notes at end of table. | ||||||||||||

| Labels a | Outside diameter D mm |

Nominal linear mass b, c T&C kg/m |

Wall thickness t mm |

Type of end-finish | ||||||||

| 1 | 2 | H40 | J55 K55 |

M65 | L80 C95 |

N80 Type 1,Q |

C90 T95 |

P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 |

65.00 75.00 84.00 109.00 |

406,40 406,40 406,40 406,40 |

96,73 111,61 125,01 162,21 |

9,53 11,13 12,57 16,66 |

PS | PSB PSB P |

PSB PSB |

P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1,105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 |

94.00 106.50 133.00 |

508,00 508,00 508,00 |

139,89 158,49 197,93 |

11,13 12,70 16,13 |

PSL — — |

PSLB PSLB PSLB |

PSLB PSLB — |

— — — |

— — — |

— — — |

— — — |

— — — |

| P = Plain end, S = Short round thread, L = Long round thread, B = Buttress thread, E = Extreme-line. | ||||||||||||

| ♦ Labels are for information and assistance in ordering. ♦ Nominal linear masses, threaded and coupled (col. 2) are shown for information only. ♦ The densities of martensitic chromium steels (L80 types 9Cr and 13Cr) are different from carbon steels. The masses shown are therefore not accurate for martensitic chromium steels. A mass correction factor of 0,989 may be used. |

||||||||||||

| Labels | Outside diameter D mm |

Plain-end linear mass kg/m |

Wall thickness t mm |

|

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 |

9.92 11.35 13.05 17.95 19.83 27.66 |

88,90 101,60 114,30 127,00 139,70 168,28 |

14,76 16,89 19,42 26,71 29,51 41,18 |

7,34 7,26 7,37 9,19 9,17 10,59 |

ISO/API Steel Tubing list

| Labels | Outside diameter D mm |

Nominal linear masses a, b |

Wall thick- ness t mm |

Type of end finish c | |||||||||||

| Non- upset T&C kg/m |

Ext. upset T&C kg/m |

Integ. joint kg/m |

|||||||||||||

| 1 | 2 | ||||||||||||||

| NU T&C |

EU T&C |

IJ | H40 | J55 | L80 | N80 Type 1,Q |

C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 |

2.40 2.75 3.65 4.42 5.15 |

— 2.90 3.73 — — |

2.40 2.76 — — — |

48,26 48,26 48,26 48,26 48,26 |

— 4,09 5,43 6,58 7,66 |

— 4,32 5,55 — — |

3,57 4,11 — — — |

3,18 3,68 5,08 6,35 7,62 |

PI PNUI PU — — |

PI PNUI PU — — |

— PNUI PU P P |

— PNUI PU — — |

— PNUI PU P P |

— PNUI PU P P |

PU — — |

| 2.063 2.063 |

3.24 4.50 |

— — |

3.25 — |

52,40 52,40 |

— — |

— — |

4,84 — |

3,96 5,72 |

PI P |

PI P |

PI P |

PI P |

PI P |

PI P |

P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 |

4.00 4.60 5.80 6.60 7.35 |

4.70 5.95 7.45 |

60,32 60,32 60,32 60,32 60,32 |

5,95 6,85 8,63 9,82 10,94 |

6,99 8,85 11,09 |

4,24 4,83 6,45 7,49 8,53 |

PN PNU |

PN PNU |

PN PNU PNU P PU |

PN PNU PNU — — |

PN PNU PNU P PU |

PN PNU PNU P PU |

PNU PNU |

||

| 2-7/8 2-7/8 2-7/8 2-7/8 |

6.40 7.80 8.60 9.35 |

6.50 7.90 8.70 9.45 |

— — — |

73,02 73,02 73,02 73,02 |

9,52 11,61 12,80 13,91 |

9,67 11,76 12,95 14,06 |

— — — |

5,51 7,01 7,82 8,64 |

PNU — — |

PNU — — |

PNU PNU PNU PU |

PNU PNU PNU — |

PNU PNU PNU PU |

PNU PNU PNU PU |

PNU PNU PNU — |

| 2-7/8 2-7/8 |

10.50 11.50 |

— | — | 73,02 73,02 |

15,63 17,11 |

— | — | 9,96 11,18 |

— | — | P P |

— | P P |

P P |

— |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 |

7.70 9.20 10.20 12.70 14.30 15.50 17.00 |

— 9.30 — 12.95 — — — |

— — — — — — — |

88,90 88,90 88,90 88,90 88,90 88,90 88,90 |

11,46 13,69 15,18 18,90 21,28 23,07 25,30 |

— 13,84 — 19,27 — — — |

— — — — — — — |

5,49 6,45 7,34 9,52 10,92 12,09 13,46 |

PN PNU PN — — — — |

PN PNU PN — — — — |

PN PNU PN PNU P P P |

PN PNU PN PNU — — — |

PN PNU PN PNU P P P |

PN PNU PN PNU P P P |

— PNU — PNU — — — |

| 4 4 4 4 4 4 |

9.50 10.70 13.20 16.10 18.90 22.20 |

— 11.00 — — — — |

— — — — — — |

101,60 101,60 101,60 101,60 101,60 101,60 |

14,14 — 19,64 23,96 28,13 33,04 |

— 16,37 — — — — |

— — — — — — |

5,74 6,65 8,38 10,54 12,70 15,49 |

PN PU — — — — |

PN PU — — — — |

PN PU P P P P |

PN PU — — — — |

PN PU P P P P |

PN PU P P P P |

— — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 |

12.60 15.20 17.00 18.90 21.50 23.70 26.10 |

12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 |

18,75 22,62 25,30 28,13 32,00 35,27 38,84 |

18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 |

PNU | PNU | PNU P P P P P P |

PNU — — — — — — |

PNU P P P P P P |

PNU P P P P P P |

|||

| P = Plain end, N = Non-upset threaded and coupled, U = External upset threaded and coupled, I = Integral joint. | |||||||||||||||

| ♦ Nominal linear masses, threads and coupling (col. 2, 3, 4) are shown for information only. ♦ The densities of martensitic chromium steels (L80 types 9Cr and 13Cr) are different from carbon steels. The masses shown are therefore not accurate for martensitic chromium steels. A mass correction factor of 0,989 may be used. ♦ Non-upset tubing is available with regular couplings or special bevel couplings. External-upset tubing is available with regular, special-bevel, or special clearance couplings. |

|||||||||||||||

Standard & Grade

Casing and tubing Standard Grades:

API 5CT J55,K55,L80, N80,P110, C90, T95, H40

API 5CT casing and tubing pipe ends :

(STC)Short round thread casing

(LC)Long round thread casing

(BC)Buttress thread casing

(XC)Extreme-line casing

(NU)Non-upset tubing

(EU)External upset tubing

(IJ)Integral joint tubing

The casing and tubing should be delivery according to above the connections with standard of API5CT / API Standards.

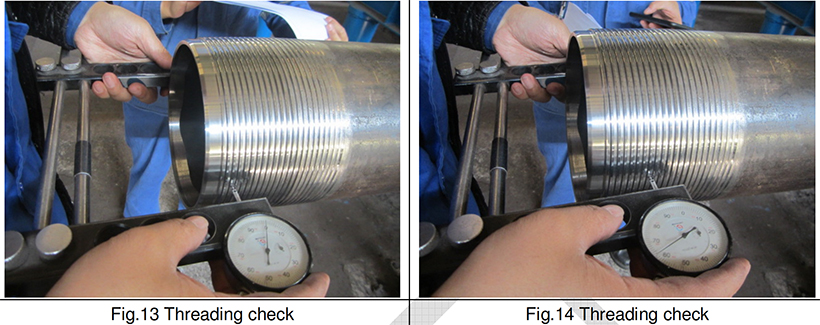

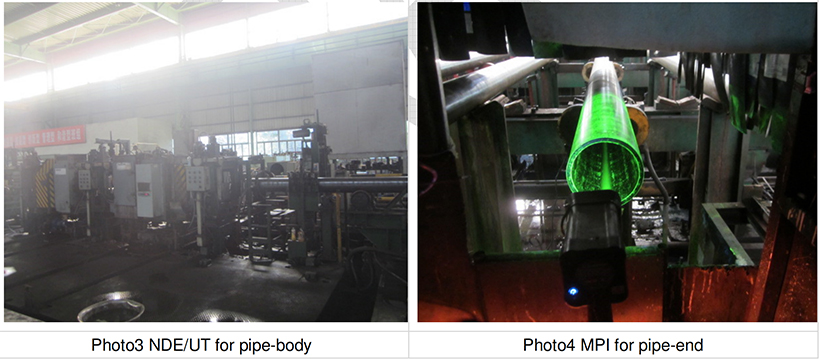

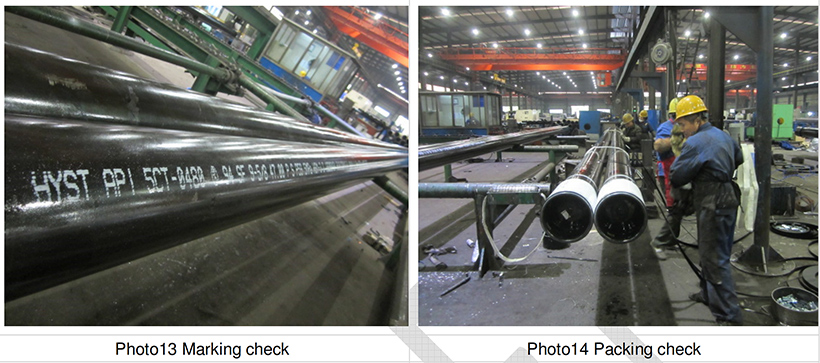

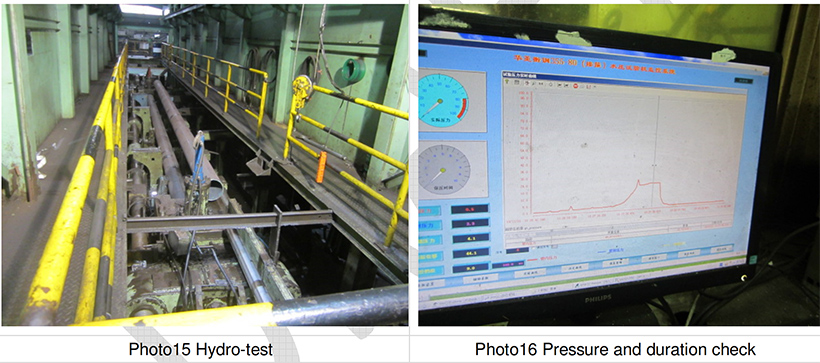

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection , Tension Test, Dimension Check, Bend Test , Flattening Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test…..

Marking, Painting before delivery.

Packing & Shipping

The packaging method for steel pipes involves cleaning, grouping, wrapping, bundling, securing, labeling, palletizing (if necessary), containerization, stowing, sealing, transportation, and unpacking. Different kinds of steel pipes and fittings with different packing methods. This comprehensive process ensures that the steel pipes shipping and arrive at their destination in optimal condition, ready for their intended use.

Usage & Application

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide.

The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...