Product Description

Seamless steel pipe is the steel pipe or tubes without weld-seam or a weld-joint. Seamless carbon steel pipes are produced by steel ingots or solid tube blanks that are perforated into capillary tubes, and then made by hot rolling, cold rolling or cold drawing, with advantaged characteristics of excellent durability and corrosion resistance.

Carbon Seamless steel pipe is a tubular section or hollow section cylinder, usually used widely to convey or transfer liquids and gases (fluids), powders and others like small solids.

Womic supplying seamless steel pipe for Onshore/Offshore, Construction Projects, Including hot rolled seamless pipes and cold drawn (rolled) seamless pipes.

Specifications

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D : E75, X95, G105, S135 |

| EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454 :STPG 370, STPG 410 |

| JIS G3456 :STPT 370, STPT 410, STPT 480 |

| GB/T 8163 :10#,20#,Q345 |

| GB/T 8162 :10#,20#,35#,45#,Q345 |

Standard & Grade

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 | Carbon Seamless steel pipe for line pipe, Petroleum, natural gas industries, pipeline transportation systems. |

| API 5CT: J55, K55, N80, L80, P110 | Carbon Seamless steel pipe for oil gas casing and tubing. |

| API 5D : E75, X95, G105, S135 | Drill pipes, drilling tubes for oil and gas. |

| EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | Carbon Seamless steel pipe for construction project. |

| ASTM A106: GR.A, GR.B, GR.C | Carbon Seamless steel pipe for construction project. |

| ASTM A53/A53M: GR.A, GR.B | Carbon Seamless steel pipe for construction project. |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 | Carbon Seamless steel pipe for high temperatures service industry. |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 | Carbon Seamless steel pipe for low temperatures industry. |

| DIN 2391: St30Al, St30Si, St35, St45, St52 | Cold drawn Carbon seamless prevision pipe |

| DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 | Seamless circular unalloyed steel tubes subject to special requirements |

| GB/T 8163 :10#, 20#, Q345 | Carbon Seamless steel pipe for common usage. |

| GB/T 8162 :10#, 20#, 35#, 45#, Q345 | Carbon Seamless steel pipe for common usage. |

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection , Tension Test, Dimension Check, Bend Test, Flattening Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test ect …..

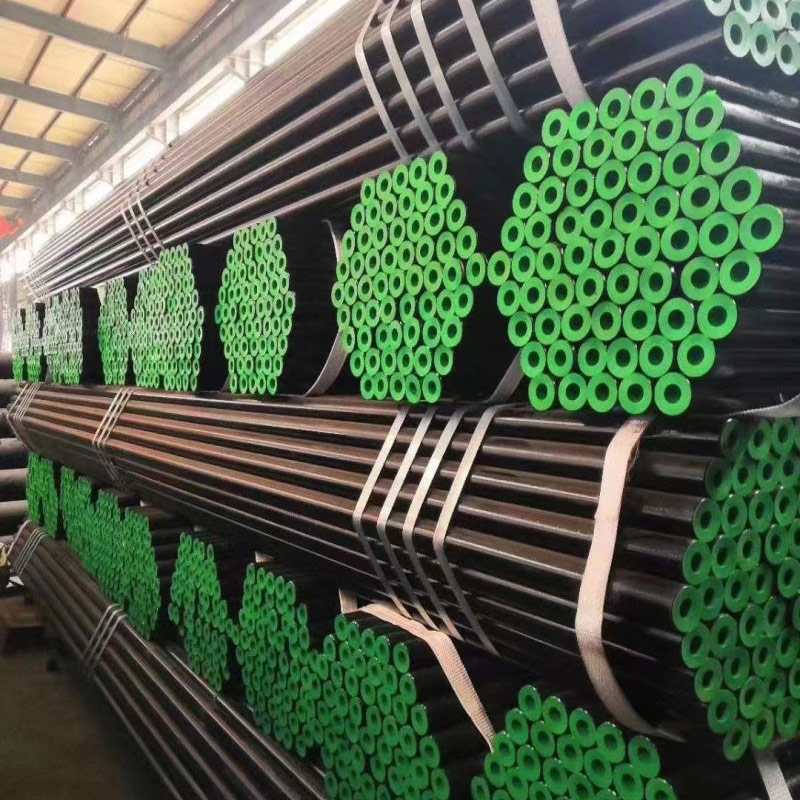

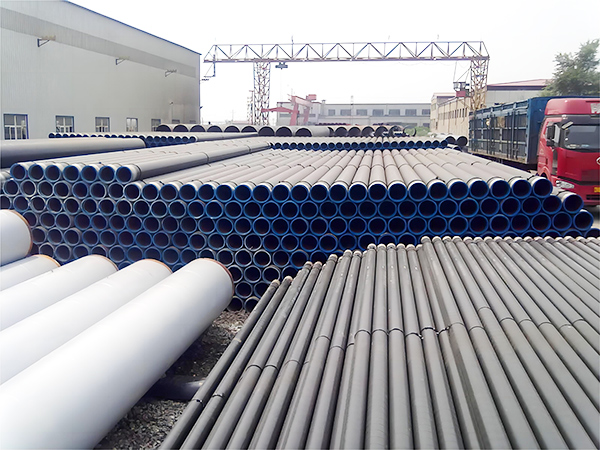

Marking, Painting before delivery.

Packing & Shipping

The packaging method for steel pipes involves cleaning, grouping, wrapping, bundling, securing, labeling, palletizing (if necessary), containerization, stowing, sealing, transportation, and unpacking. Different kinds of steel pipes and fittings with different packing methods. This comprehensive process ensures that the steel pipes shipping and arrive at their destination in optimal condition, ready for their intended use.

Usage & Application

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide.

The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...