Product Description

A valve is a fundamental mechanical device used to control the flow of fluids, gases, or other media through a piping system. Valves serve a crucial role in various industries, ensuring precision control, safety, and efficiency in fluid transportation and process management.

Key Functions:

Valves are designed to perform several essential functions, including:

● Isolation: Shutting off or opening the flow of media to isolate different sections of a system.

● Regulation: Adjusting the flow rate, pressure, or direction of media to meet specific requirements.

● Back flow Prevention: Preventing the reversal of media flow to maintain system integrity.

● Safety: Releasing excess pressure to prevent system overloads or ruptures.

● Mixing: Blending different media to achieve desired compositions.

● Diversion: Redirecting media to different paths within a system.

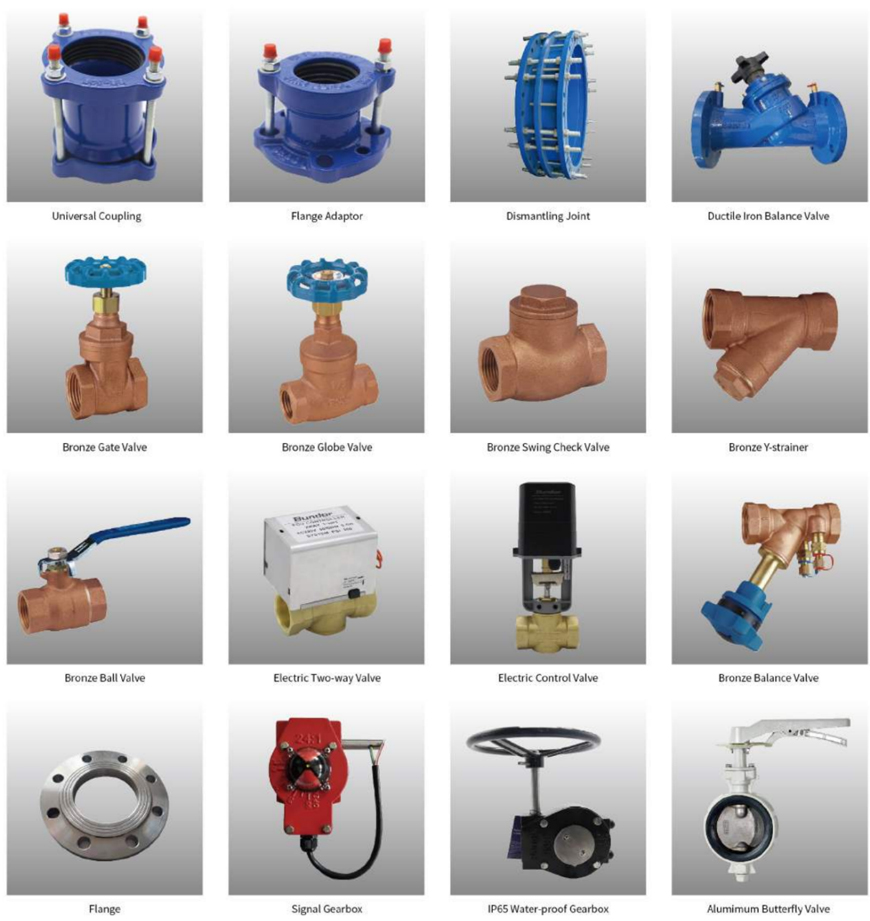

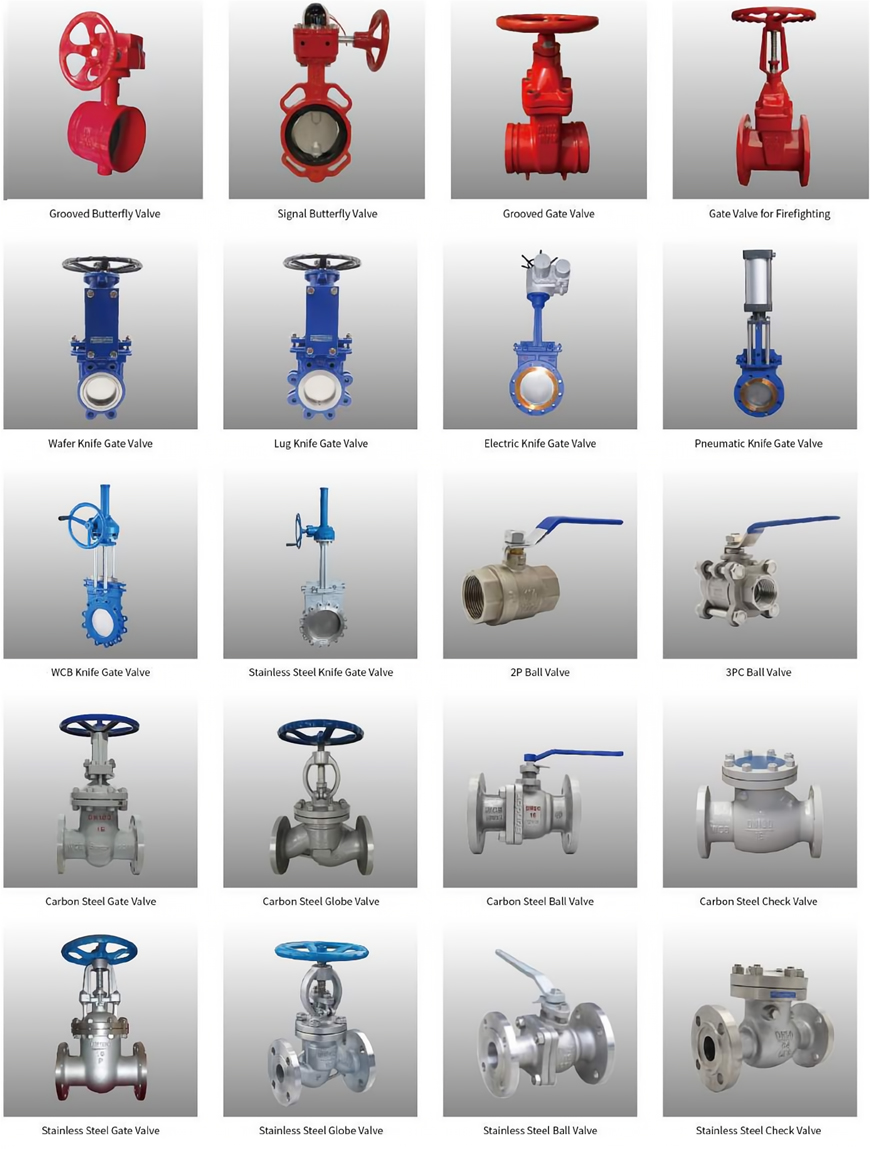

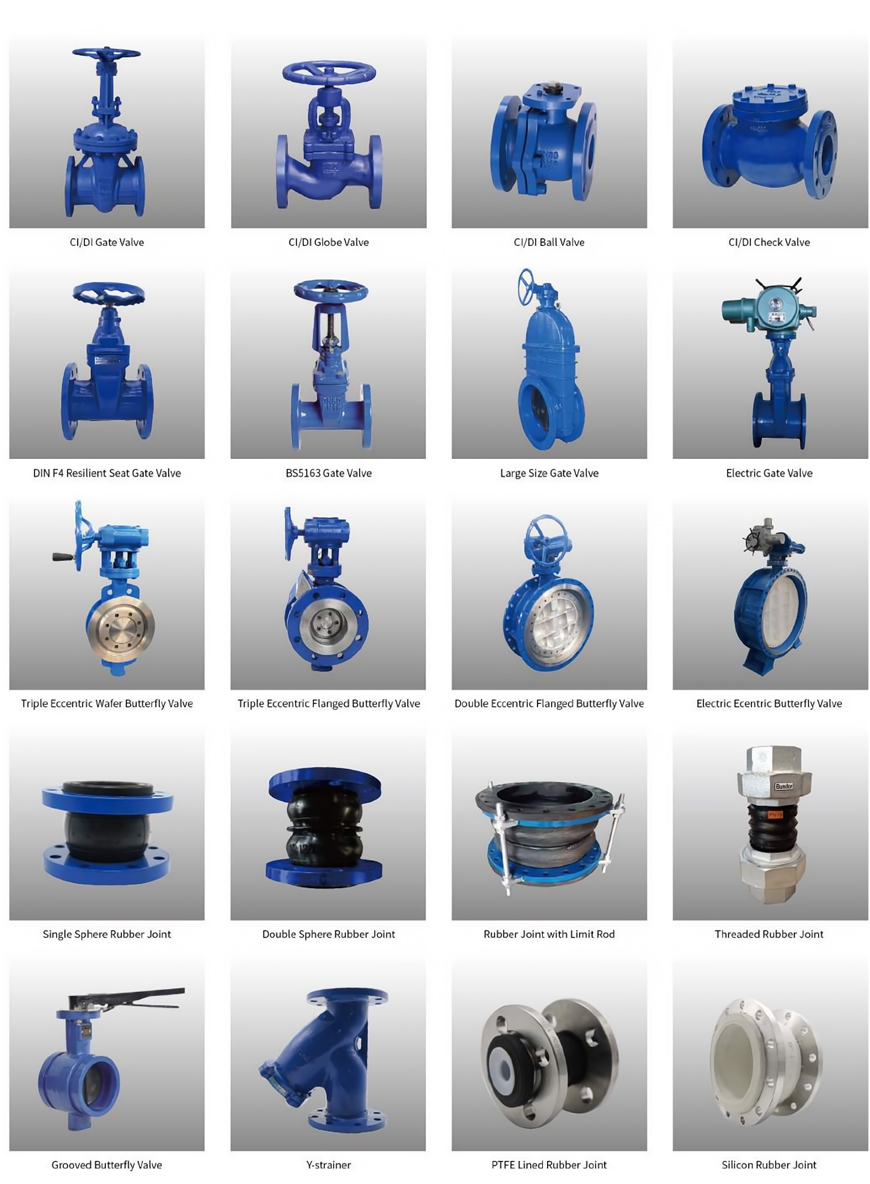

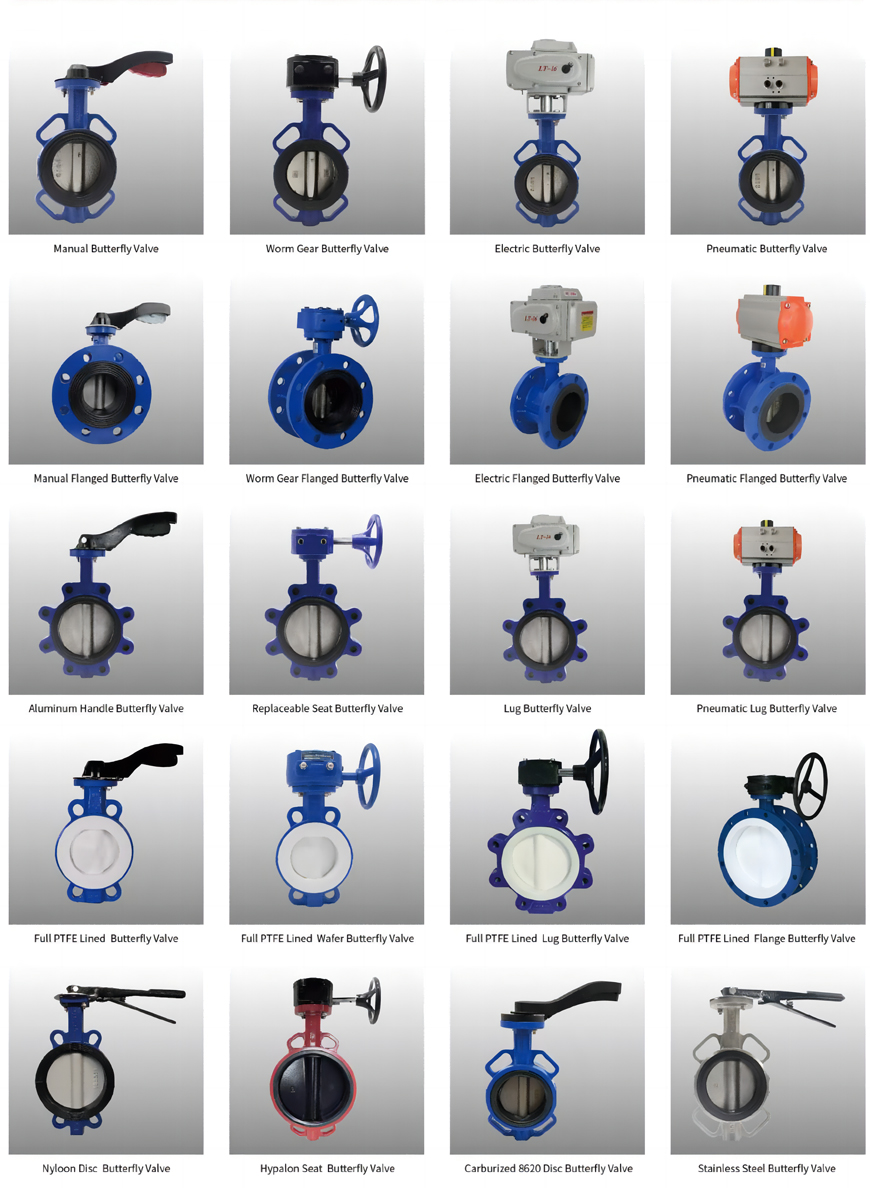

Types of Valves:

There is a wide variety of valve types, each designed to cater to specific applications and industries. Some common valve types include gate valves, globe valves, ball valves, check valves, butterfly valves, and control valves.

Components:

A typical valve consists of several components, including the body, which houses the mechanism; the trim, which controls the flow; the actuator, which operates the valve; and the sealing elements, which ensure tight closure.

Specifications

| API 600: Cast Iron, Cast Steel, Stainless Steel |

| API 602: Carbon Steel, Stainless Steel, Alloy Steel |

| API 609: Carbon Steel, Stainless Steel, Alloy Steel |

| API 594: Carbon Steel, Stainless Steel |

| EN 593: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| API 598: Carbon Steel, Stainless Steel, Alloy Steel |

| API 603: Stainless Steel, Alloy Steel |

| DIN 3352: Cast Iron, Cast Steel |

| JIS B2002: Cast Iron, Cast Steel, Stainless Steel |

| BS 5153:Cast Iron, Cast Steel |

Standard & Grade

|

API 6D: Specification for Pipeline Valves - End Closures, Connectors, and Swivels |

Materials: Carbon Steel, Stainless Steel, Alloy Steel |

|

API 609: Butterfly Valves: Double Flanged, Lug- and Wafer-Type |

Materials: Carbon Steel, Stainless Steel, Alloy Steel |

|

API 594: Check Valves: Flanged, Lug, Wafer, and Butt-Welding Ends |

Materials: Carbon Steel, Stainless Steel

|

|

EN 593: Industrial Valves - Metallic Butterfly Valves |

Materials: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

|

API 598: Valve Inspection and Testing |

Materials: Carbon Steel, Stainless Steel, Alloy Steel |

|

API 603: Corrosion-Resistant, Bolted Bonnet Gate Valves - Flanged and Butt-Welding Ends |

Materials: Stainless Steel, Alloy Steel |

|

DIN 3352: Resilient Seated Cast Iron Gate Valves |

Materials: Cast Iron, Cast Steel |

|

JIS B2002: Butterfly Valves |

Materials: Cast Iron, Cast Steel, Stainless Steel |

|

BS 5153: Specification for Cast Iron and Carbon Steel Swing Check Valves |

Materials: Cast Iron, Cast Steel |

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection, Dimension Check, Bend Test , Flattening Test, Impact Test, DWT Test, Non-Destructive Examination, Hardness Test, Pressure Testing, Seat Leakage Testing, Flow Performance Testing, Torque and Thrust Testing, Painting and Coating Inspection, Documentation Review…..

Usage & Application

Valves are essential components that play a pivotal role in various industries by regulating, controlling, and directing the flow of fluids, gases, and steam. Their versatile functionality ensuring optimal performance, safety, and efficiency across diverse applications.

The valves we Womic Steel produced widely used for Industrial Processes,Oil and Gas,Water Treatment,Energy Generation,HVAC Systems,Chemical Industry,Pharmaceuticals,Automotive and Transportation,Agriculture and Irrigation,Food and Beverage,Mining and Minerals,Medical Applications,Fire Protection etc...

Valves' adaptability, precision, and reliability make them indispensable across numerous industries, safeguarding operations, optimizing processes, and enhancing overall safety and efficiency.

Packing & Shipping

Packing:

Each valve is carefully inspected and tested before packing to ensure it meets our rigorous quality standards.Valves are individually wrapped and protected using industry-approved materials to prevent any damage during transportation.We provide customized packaging options based on the valve type, size, and specific customer requirements.

All necessary accessories, documentation, and installation instructions are included in the package.

Shipping:

We collaborate with reputable shipping partners to guarantee reliable and timely delivery to your specified destination.Our logistics team optimizes shipping routes to minimize transit times and reduce the risk of delays.For international shipments, we handle all necessary customs documentation and compliance to facilitate smooth customs clearance.We offer flexible shipping options, including expedited shipping for urgent requirements.