Product Description

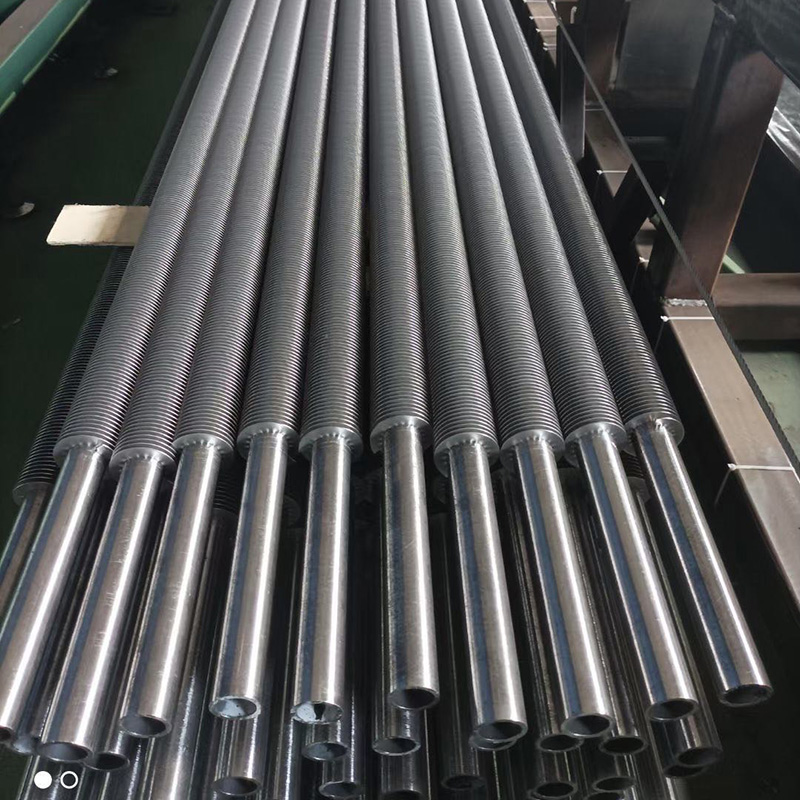

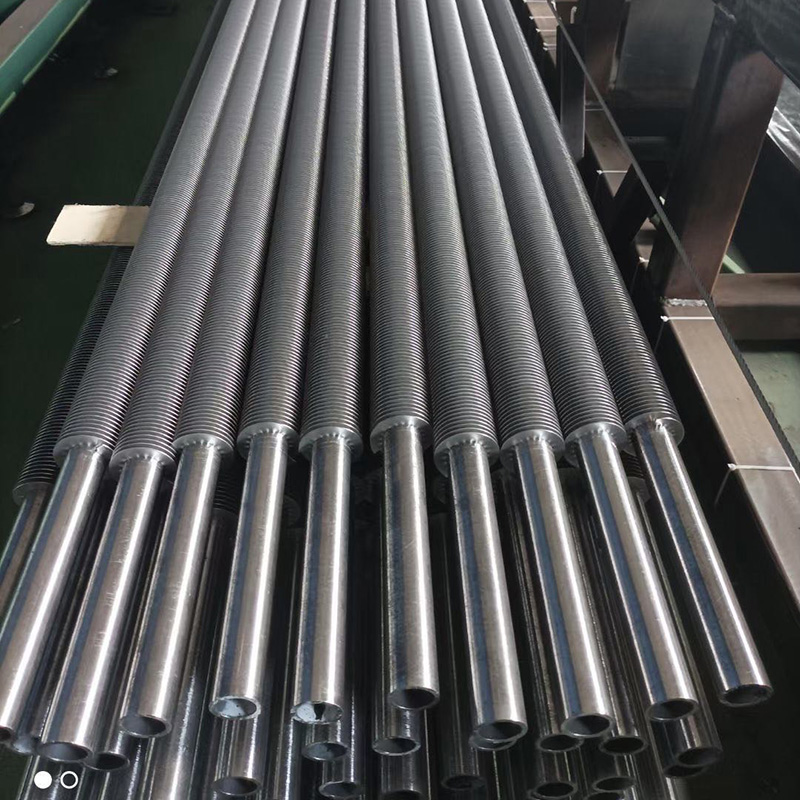

Steel boiler pipe specifications with overall dimensions (such as the diameter or length) and the wall thickness, steel boiler pipe can be used in the pipeline, thermal technology equipment, industrial machinery, petroleum geological exploration, containers, chemical industry, and other special purpose.

Steel Boiler tubes/pipes are manufactured in seamless pipes, be made of carbon steel materials or alloy steel. Boiler tubes/pipes are widely used in steam boilers, heat exchangers, power gereration, fossil fuel plants, industrial processing plants, electric power plants, sugar production mills ect. Boiler tubes or pipes often used as medium-pressure boiler or high-pressure boiler pipes.

Specifications

| ASTM A179 |

| ASTM A192 |

| ASTM A209: Gr.T1, Gr. T1a, Gr. T1b |

| ASTM A210:Gr.A1, Gr.C |

| ASTM A106: Gr.A, Gr.B, Gr.C |

| DIN 17175: ST35.8, ST45.8, 15Mo3, 13CrMo44 |

| EN 10216-2: P235GH, P265GH, 16Mo3, 10CrMo5-5, 13CrMo4-5 |

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A178:Gr.A, Gr.C |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H etc... |

| ASTM A269/A269M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H etc... |

| EN 10216-5:1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 |

Standard & Grade

Boiler Tubes Standard Grades:

ASME SA-179M, ASME SA-106, ASTM A178, ASME SA-192M, EN10216-1, JIS G3461, ASME SA-213M, DIN17175, DIN1629.

Delivery Condition: Annealed, normalized, tempered. surface oiled, black painted, shot blasted, hot dipped galvanized.

| ASME SA-179M: | Seamless Cold Drawn Low Carbon Steel Heat Exchanger and Condenser Tubes. |

| ASME SA-106: | Carbon Steel Pipe For High Temperature Service. |

| ASTM A178: | Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes. |

| ASME SA-192M: | Seamless Carbon Steel Boiler Tubes for High Pressure Devices. |

| ASME SA-210M: | Seamless Medium Carbon Steel Boiler and Superheater Tubes. |

| EN10216-1/2: | Seamless non-alloy steel tubes for pressure purposes with specified room temperature properties. |

| JIS G3454: | Carbon steel pipes for pressure service at an approximate maximum temperature of 350 Degrees Celsius |

| JIS G3461: | Carbon Steel Tubes for Boiler and Heat Exchanger. |

| GB 5310: | Seamless steel tubes and pipes for high pressure boiler. |

| ASME SA-335M: | Seamless ferritic and austenitic alloy steel boiler, superheater and heat-exchanger tube. |

| ASME SA-213M: | Alloy Steel Tubes for boilers, superheaters and heat exchangers. |

| DIN 17175: | Seamless Steel Tubes for Boiler Industry, heat-resisting seamless steel tube, used for the pipelines of boiler industry. |

| DIN 1629: | Overheated boilers, manufacturing pipeline, vessel, equipment, pipe fittings, and as heat exchangers via austenitic pipes. |

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection , Tension Test, Dimension Check, Bend Test , Flattening Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test…..

Marking, Painting before delivery.

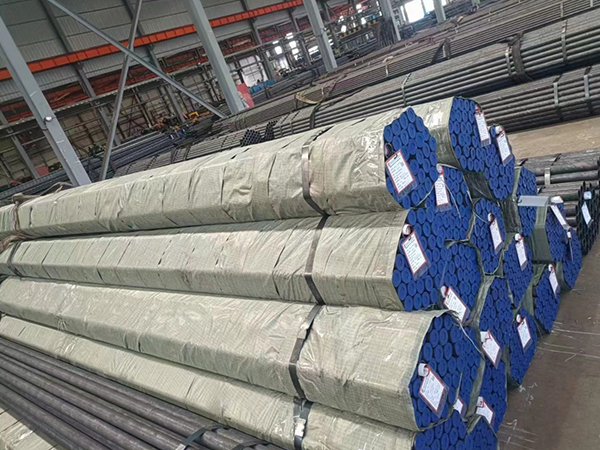

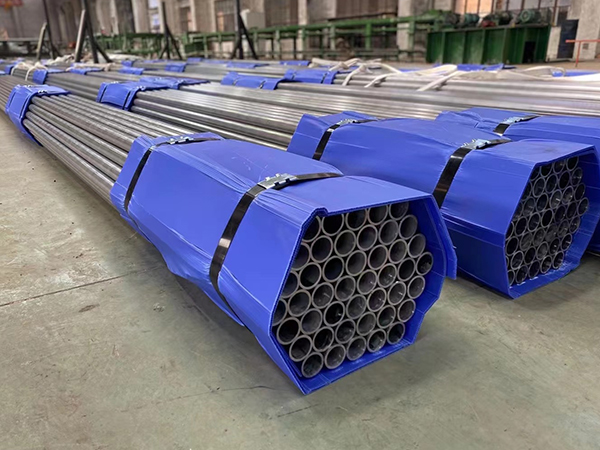

Packing & Shipping

The packaging method for steel pipes involves cleaning, grouping, wrapping, bundling, securing, labeling, palletizing (if necessary), containerization, stowing, sealing, transportation, and unpacking. Different kinds of steel pipes and fittings with different packing methods. This comprehensive process ensures that the steel pipes shipping and arrive at their destination in optimal condition, ready for their intended use.

Usage & Application

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide.

The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...