Womic Steel has established itself as a trusted provider of high-quality materials and solutions over 20 years. With a commitment to excellence, the company caters to a wide range of industries, offering tailored solutions to meet specific needs. Their inventory, which includes premium ASTM A335 P91 Type 2 materials, is sourced from approved international manufacturers and is continuously updated to meet the highest standards. Womic Steel specializes in supplying P91 materials for high-energy applications, including pipes, fittings, valves, flanges, and more, ensuring customers receive the best-performing products.

Standars can be supplied from Womic Steel Group:

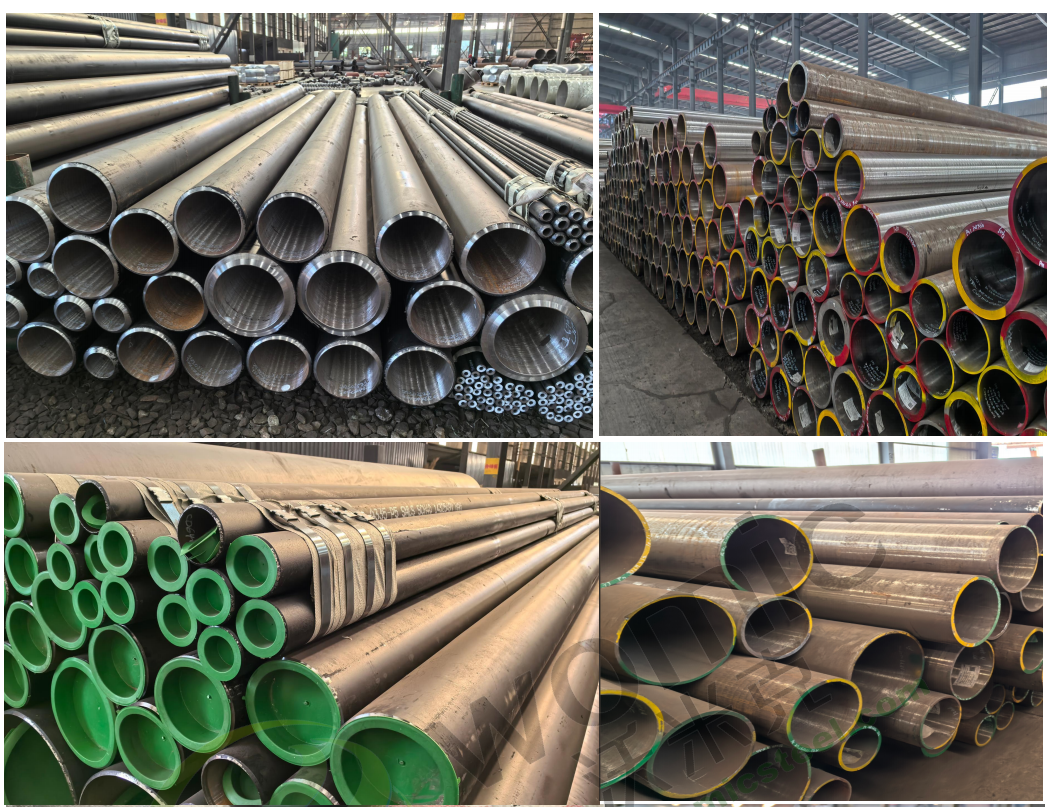

A335 Chrome Moly Pipes

A335 Alloy Steel Pipes

A335 P5 Alloy Steel Pipes

A335 P9 Alloy Steel Pipes

A335 P11 Alloy Steel Pipes

A335 P12 Alloy Steel Pipes

A335 P22 Alloy Steel Pipes

A335 P91 Alloy Steel Pipes

Key Features of ASTM A335 P91 Type 2 tubes

ASTM A335 P91 Type 2 is a chrome-moly alloy steel known for its exceptional strength, temperature resistance, and creep strength. It is classified as a creep strength-enhanced ferritic (CSEF) steel, making it ideal for high-temperature and high-pressure applications. The material undergoes a specific heat treatment process:

Normalizing at 1050 °C.

Air cooling to 200 °C.

Tempering at 760 °C.

This process enhances its creep strength and durability, making it a superior choice for demanding environments.

Composition and Benefits of ASTM A335 P91 Steel Tubes

Chromium (9%): Enhances high-temperature strength, oxidation resistance, and mechanical properties.

Molybdenum (1%): Improves elasticity, wear resistance, and high-temperature creep strength.

Vanadium and Columbium/Niobium: Further enhance creep strength and thermal fatigue resistance.

Advantages of ASTM A335 P91 Steel Tubes

Reduced wall thickness: Allows for lighter components, reduced welding time, and less filler metal.

Higher thermal fatigue life: Up to 10 times better than predecessors like T22 or P22.

Increased operating temperatures: Improves efficiency in high-temperature applications.

Applications of ASTM A335 P91 Steel Tubes

P91 is widely used in industries that require materials capable of withstanding extreme temperatures and pressures. Common applications include:

Power generation: Boilers, reheat lines, and combined cycle plants.

Petrochemical plants: Heaters, gas processing equipment, and oilfield services.

High-temperature piping systems: Suitable for bending, flanging, and welding operations.

Chemical Composition of ASTM A335 P91 Steel Tubes

The chemical composition of P91 ensures its superior performance:

Carbon: 0.08% – 0.12%

Manganese: 0.30% – 0.60%

Chromium: 8.00% – 9.50%

Molybdenum: 0.85% – 1.05%

Vanadium: 0.18% – 0.25%

Nitrogen: 0.030% – 0.070%

Other elements: Nickel, aluminum, columbium, titanium, and zirconium in controlled amounts.

Mechanical Properties

Tensile Strength: Minimum 85,000 PSI (585 MPa).

Yield Strength: Minimum 60,000 PSI (415 MPa).

Welding and Heat Treatment ASTM A335 P91 Steel Tubes

Welding P91 requires strict adherence to procedures to maintain its properties:

Preheating: Essential to prevent hydrogen-induced cracking.

Inter-pass temperature control: Maintained using modern induction heating systems.

Post-weld heat treatment (PWHT): Critical to achieve the desired microstructure and avoid failures.

Welding electrodes: Must match the parent material’s composition.

Why Choose Womic Steel ASTM A335 P91 Steel Tubes?

Extensive inventory: High-quality P91 materials for all your needs.

Expertise: Experienced team to guide you through material selection and application.

Commitment to quality: Only the best materials from approved manufacturers.

For all your ASTM A335 P91 Type 2 requirements, contact Womic Steel today. Their team is ready to provide solutions that exceed your expectations and deliver the highest quality materials for your projects.