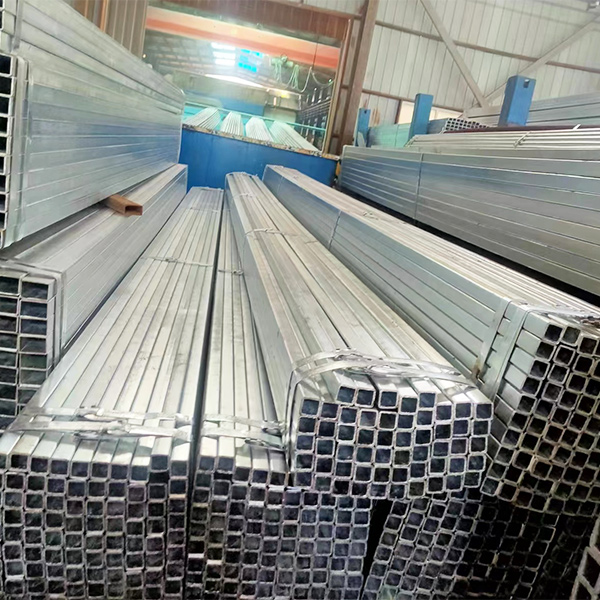

Product Description

Galvanized steel pipes are steel pipes that produced in dipped protective zinc coating to prevent corrosion and rust. Galvanized steel pipe can be divided into hot dip galvanizing pipe and pre-galvanizing pipe. The hot-dip galvanizing layer is thick, with uniform plating, strong adhesion and long service life.

Steel scaffolding pipes also a kind of galvanized pipes is a scaffolding for both interior and exterior work, made of tube steel. Scaffolding pipes are lightweight, offer low wind resistance, and scaffolding pipes easily assembled and dismantled. Galvanized scaffolding pipes are available in several lengths for varying heights and types of work.

Scaffolding system or tubular scaffolds are scaffolds made up of galvanized aluminium or steel tubes connected together by a coupler which relies on friction to support loading.

Galvanized Steel Pipe advantages:

Galvanized steel pipe maintains a wide range of advantages, suitably used in highly corrosive environments.

Main advantages of galvanized structural pipe include:

- Protects against corrosion and rust

- Increased structural longevity

- Overall enhanced reliability

- Affordable protection

- Easy to inspect

- Less repairs

- Rugged toughness

- Easier to maintain than standard painted pipes

- Protected by advanced ASTM standardization

Galvanized Steel Pipes Applications:

- Galvanized steel pipe is an excellent choice for many applications and processing techniques.

Some common applications for galvanized steel pipe include:

- Plumbing assemble

- Construction projects

- Hot and cold liquid transportation

- Bollards

- Exposed environments used pipes

- Marine environments used pipes

- Railings or Handrails

- Fence Posts and Fencing

- Galvanized pipe can also be sawed, torched, or welded with the proper protection.

Steel Galvanized structural pipe can also used for numerous types of applications where corrosion resistance is required.

Specifications

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| BS 1387: Class A, Class B |

| ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Grade C250 , Grade C350, Grade C450 |

| SANS 657-3: 2015 |

Standard & Grade

| BS1387 | Construction fields galvanized scaffolding |

| API 5L PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 | ERW Pipes for transport oil, natural gas |

| ASTM A53: GR.A, GR.B | ERW Steel Pipes for structural and construction |

| ASTM A252 ASTM A178 | ERW Steel Pipes for pilling construction projects |

| AN/NZS 1163 AN/NZS 1074 | ERW Steel Pipes for structural construction projects |

| EN10219-1 S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | ERW Pipes used to convey fluids at low / medium pressures such as oil, gas, steam, water, air |

| ASTM A500/501, ASTM A691 | ERW Pipes for convey fluids |

| EN10217-1, S275, S275JR, S355JRH, S355J2H | |

| ASTM A672 | ERW Pipes for high pressure usage |

| ASTM A123/A123M | for hot-dip galvanized coatings on stainless steel and galvanized steel products |

| ASTM A53/A53M: | seamless and welded black, hot-dip galvanized and black coated steel pipe for general purposes. |

| EN 10240 | for metallic coverings, including galvanizing, of seamless and welded steel pipes. |

| EN 10255 | conveying non-hazardous liquids, including hot-dip galvanized coating. |

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection , Tension Test, Dimension Check, Bend Test , Flattening Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test…..

Marking, Painting before delivery.

Packing & Shipping

The packaging method for steel pipes involves cleaning, grouping, wrapping, bundling, securing, labeling, palletizing (if necessary), containerization, stowing, sealing, transportation, and unpacking. Different kinds of steel pipes and fittings with different packing methods. This comprehensive process ensures that the steel pipes shipping and arrive at their destination in optimal condition, ready for their intended use.

Usage & Application

Galvanized pipe is a steel pipe that has been hot-dip galvanized and coated with a layer of zinc to improve its corrosion resistance and service life. Galvanized pipe has a wide range of uses in a variety of areas, including but not limited to:

1. Construction field:

Galvanized pipes are often used in building structures, such as stair handrails, railings, steel structural frames, etc. Due to the corrosion resistance of the zinc layer, galvanized pipes can be used outdoors and in humid environments for a long time and are not prone to rust.

2. Water supply and drainage systems:

Galvanized pipes are widely used in water supply and drainage systems to transport drinking water, industrial water, and sewage. Its corrosion resistance makes it a reliable choice for reducing pipe blockage and corrosion problems.

3. Oil and Gas Transmission:

Galvanized pipe is commonly used in pipeline systems that transport oil, natural gas, and other liquids or gases. The zinc layer protects the pipes from corrosion and oxidation in the environment.

4. HVAC Systems:

Galvanized pipes are also used in heating, ventilation and air conditioning systems. Since these systems are subject to a variety of environmental conditions, the corrosion resistance of galvanized pipe can extend its service life.

5. Road Guardrails:

Galvanized pipes are often used to manufacture road guardrails to provide traffic safety and marking of road boundaries.

6. Mining and Industrial Sector:

In the mining and industrial sector, galvanized pipes are used to transport ores, raw materials, chemicals, etc. Its corrosion resistance and strength properties make it suitable for use in these harsh environments.

7. Agricultural fields:

Galvanized pipes are also commonly used in agricultural fields, such as as pipes for farm irrigation systems, because of their ability to resist corrosion in the soil.

In summary, galvanized pipes have important applications in many different fields, from construction to infrastructure to industry and agriculture due to their corrosion resistance and versatility.

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide.

The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...