Product Description

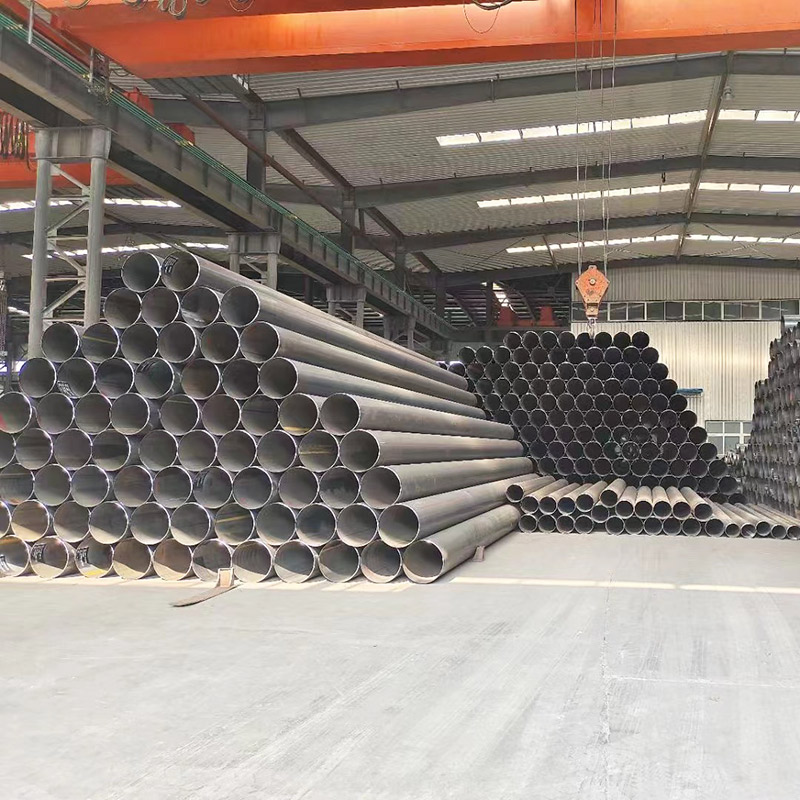

Electrical Resistance Welding, ERW Steel Pipes are manufactured by cold forming of steel coil into a round cylindrical shape. ERW Pipes was done with the low frequency A.C. current to heat the edges at first. Now high frequency A.C. instead of the low frequency process current to produce a higher quality weld.

ERW steel pipes are manufactured with low frequency or high frequency electrical resistance. ERW Steel Pipes are round tubes welded from steel plates with longitudinal welds. It is used to transport gas and liquid objects such as oil and natural gas, and can meet various high and low pressure requirements.

ERW steel pipes are widely used in fencing, line pipe, scaffolding etc.

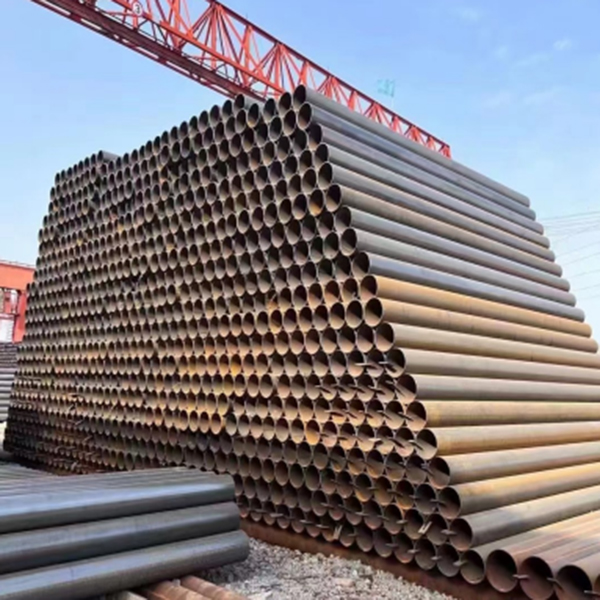

ERW steel pipes are produced in various diameters, wall thickness, finish and grades.

Main applications

● ERW Pipes used in Water pipelines

● Agriculture & irrigation (Water mains, industrial water pipe lines, plant piping, deep tube-wells & casing pipes, sewerage piping)

● Gas pipe lines

● LPG and other non-toxic gas lines

Specifications

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| BS 1387: Class A, Class B |

| ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Grade C250 , Grade C350, Grade C450 |

| SANS 657-3: 2015 |

Standard & Grade

| API 5L PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 | ERW Pipes for transport oil, natural gas |

| ASTM A53: GR.A, GR.B | ERW Steel Pipes for structural and construction |

| ASTM A252 ASTM A178 | ERW Steel Pipes for pilling construction projects |

| AN/NZS 1163 AN/NZS 1074 | ERW Steel Pipes for structural construction projects |

| EN10219-1 S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | ERW Pipes used to convey fluids at low / medium pressures such as oil, gas, steam, water, air |

| ASTM A500/501, ASTM A691 | ERW Pipes for convey fluids |

| EN10217-1, S275, S275JR, S355JRH, S355J2H | |

| ASTM A672 | ERW Pipes for high pressure usage |

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection , Tension Test, Dimension Check, Bend Test , Flattening Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test…..

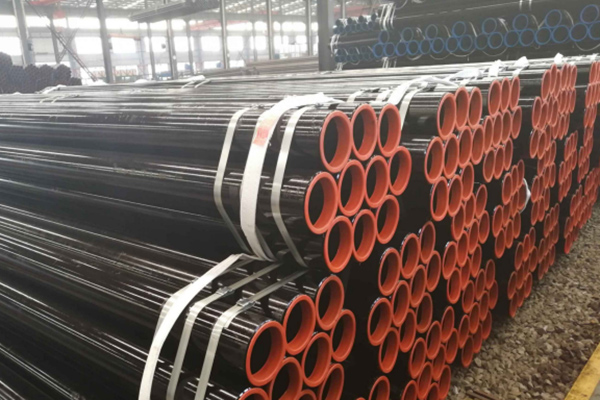

Marking, Painting before delivery.

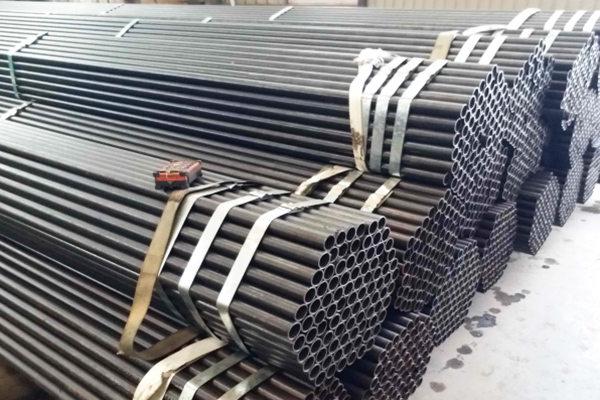

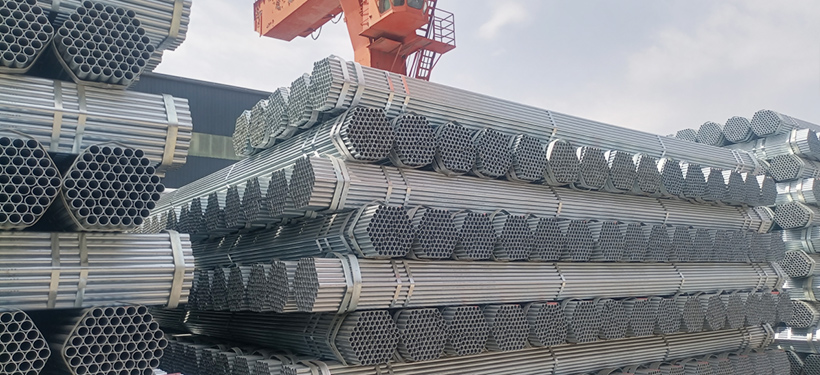

Packing & Shipping

The packaging method for steel pipes involves cleaning, grouping, wrapping, bundling, securing, labeling, palletizing (if necessary), containerization, stowing, sealing, transportation, and unpacking. Different kinds of steel pipes and fittings with different packing methods. This comprehensive process ensures that the steel pipes shipping and arrive at their destination in optimal condition, ready for their intended use.

Usage & Application

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide.

The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...