Pipes according to the use and pipe materials, commonly used connection methods are: threaded connection, flange connection, welding, groove connection (clamp connection), ferrule connection, card pressure connection, hot melt connection, socket connection and so on.

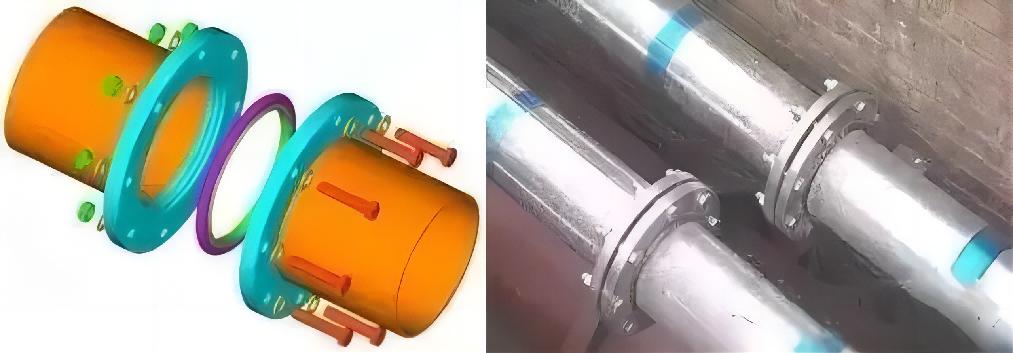

1.Flange Connection

Larger diameter pipes are connected by flanges, and flange connections are generally used in the main connection valves, check valves, water meters, pumps, etc., as well as the need for frequent disassembly and maintenance of the pipe section. Galvanized pipe such as welding or flange connection, welding should be secondary galvanized or corrosion.

2.Welding

Welding applies to non-galvanized steel pipe, mostly used for concealed piping and larger diameter piping, and more applications in high-rise buildings. Copper pipe connection can use special joints or welding, when the pipe diameter is less than 22mm socket or casing welding is appropriate, socket should meet the media flow direction installation, when the pipe diameter is greater than or equal to 22mm is appropriate to use butt welding. Stainless steel pipe can be socket welding.

3.Screw Connection

Threaded connection is the use of pipe fittings with threaded connection, pipe diameter less than or equal to 100mm of galvanized steel pipe should be threaded connection, mostly used for open pipe. Steel-plastic composite pipe is generally also used threaded connection. Galvanized steel pipe should be threaded connection, set of silk buckle when the destruction of the galvanized layer surface and the exposed threaded part should be done to prevent corrosion; should be used for flange or ferrule type special fittings to connect the galvanized steel pipe and the flange of the weld should be galvanized for the second time.

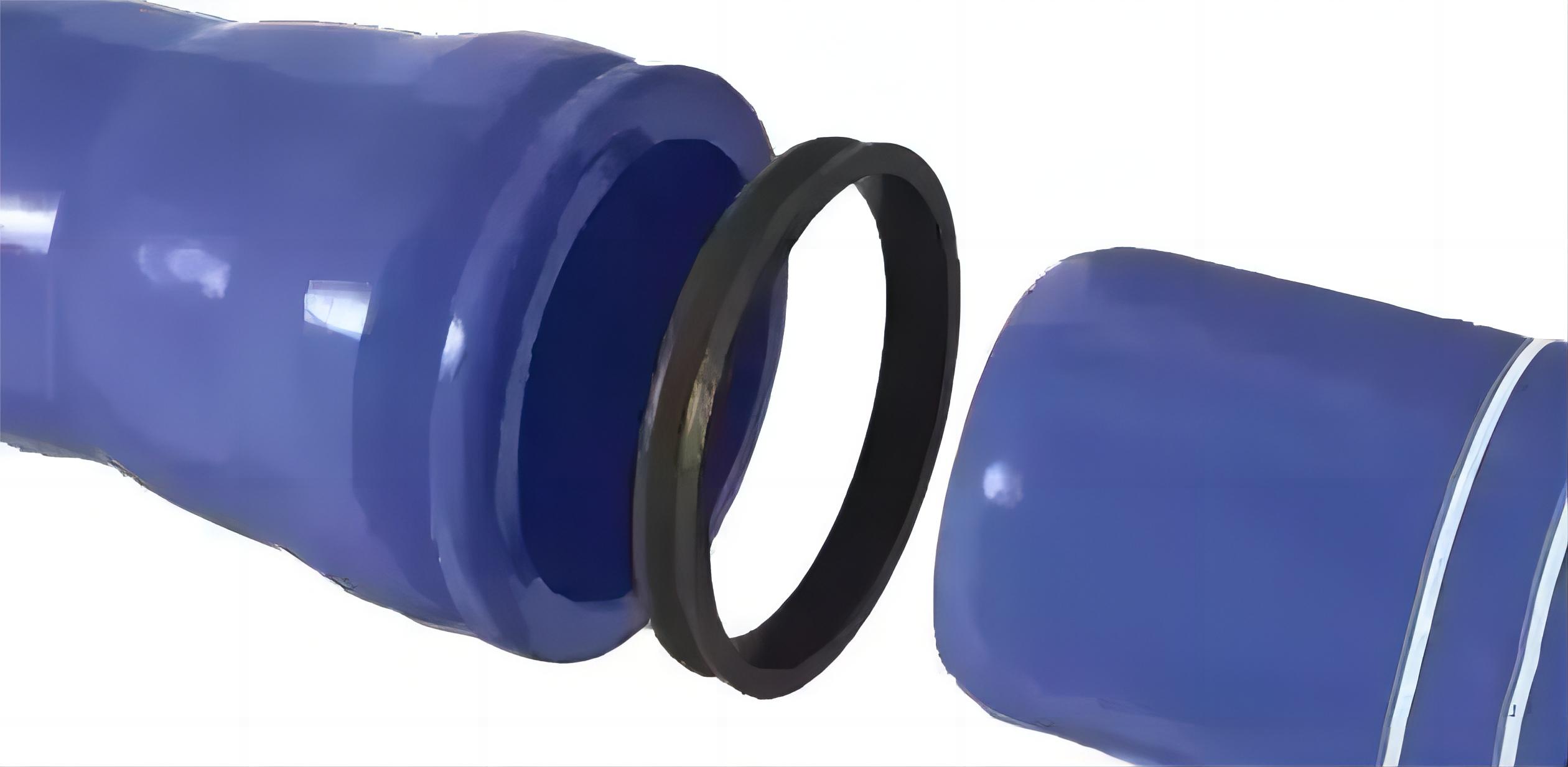

4.Socket Connection

Used for water supply and drainage cast iron pipe and pipe fittings connection. There are two types of flexible connections and rigid connections, flexible connections are sealed with rubber rings, rigid connections are sealed with asbestos cement or expansive fillers, and lead seals are available for important occasions.

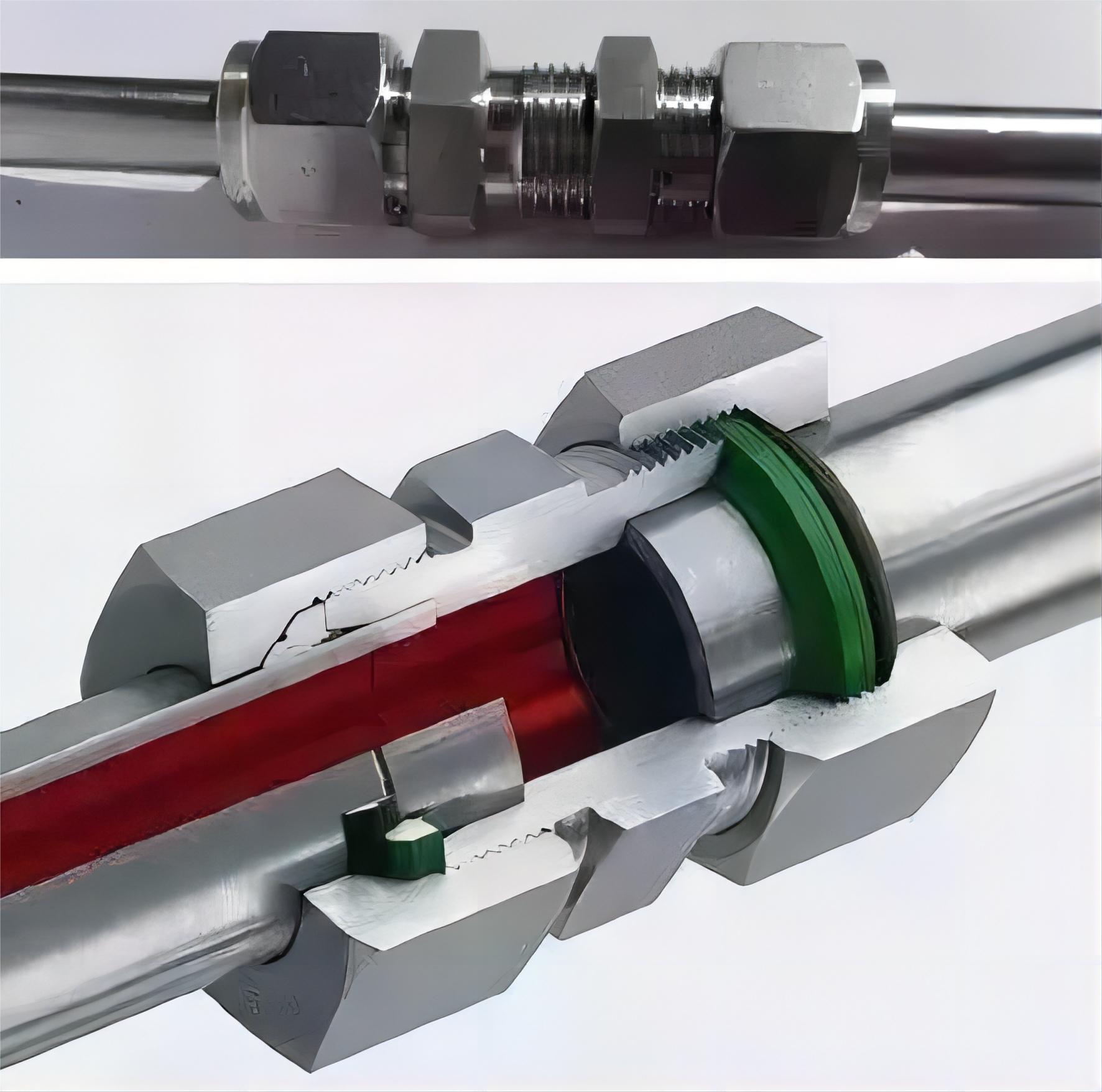

5.Ferrule Connection

Aluminum-plastic composite pipes are generally crimped with threaded ferrules. Fittings nut in the pipe end, and then the fittings core into the end, with a wrench to tighten the fittings and nuts can be. Copper pipe connection can also be used threaded ferrule crimping.

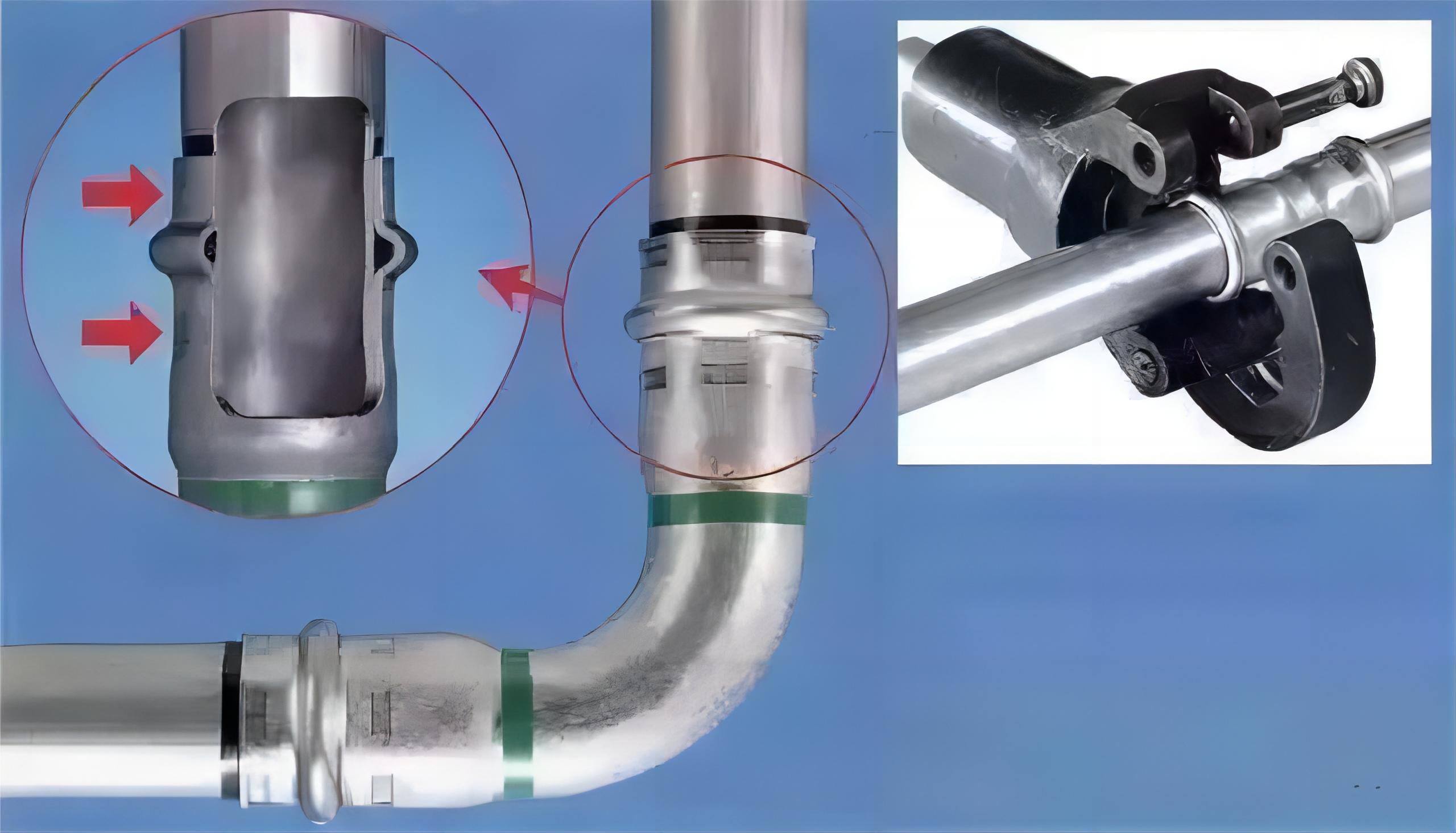

6. Clamp Connection

Stainless steel compression fittings connection technology to replace the threaded, welded, glued and other traditional water supply pipe connection technology, with the protection of water hygiene, corrosion resistance, long service life and so on, the construction of the special sealing ring with a special socket fittings and pipeline connection, the use of special tools to tighten the mouth of the pipe to play a sealing and tightening effect, the construction of the installation is convenient, reliable and economically rational connection and other advantages.

7.Hotmelt Connection

The connection method of PPR pipe is heat fusion connection by heat fusion device.

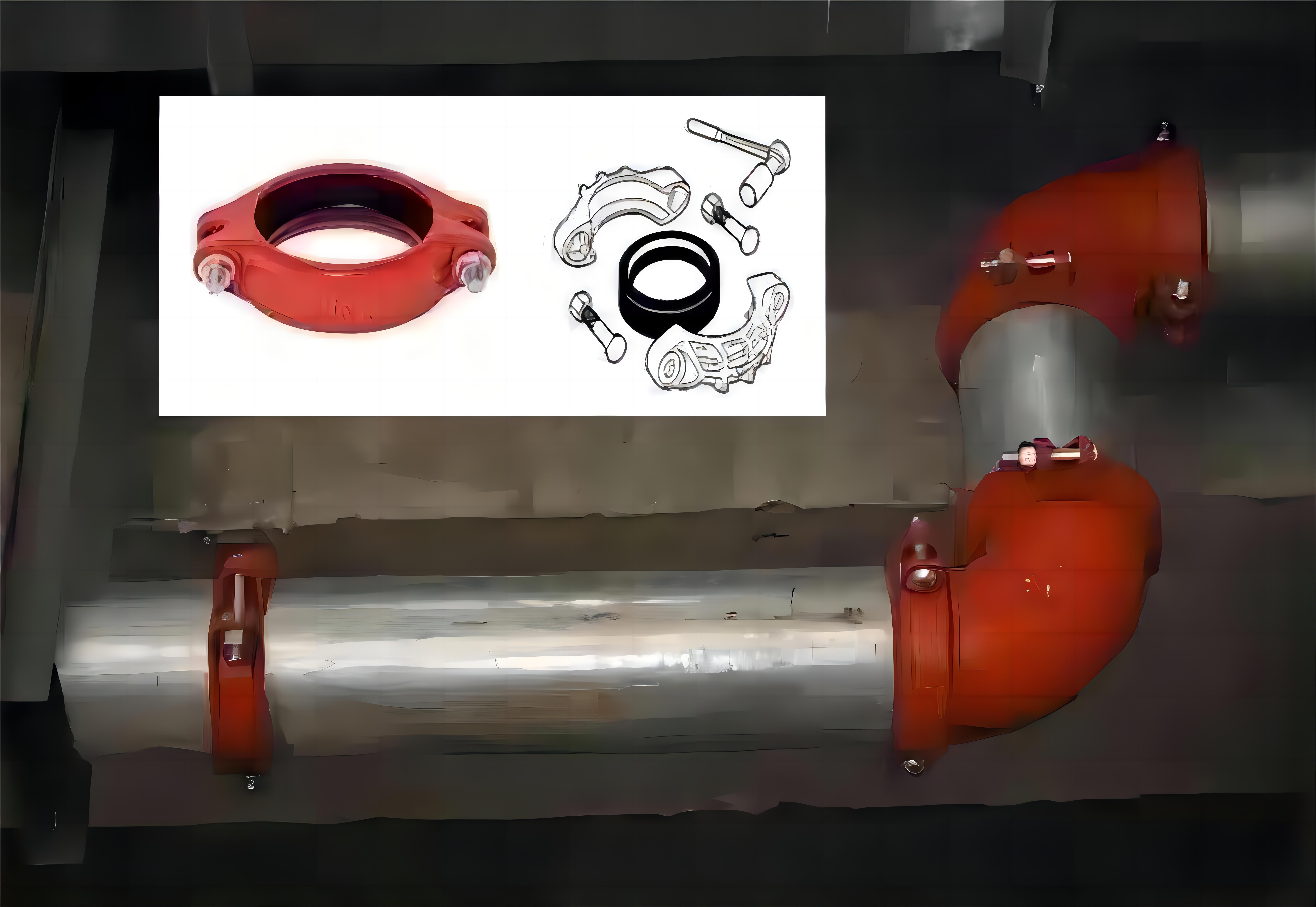

8.Groove Connect

Post time: Nov-06-2023