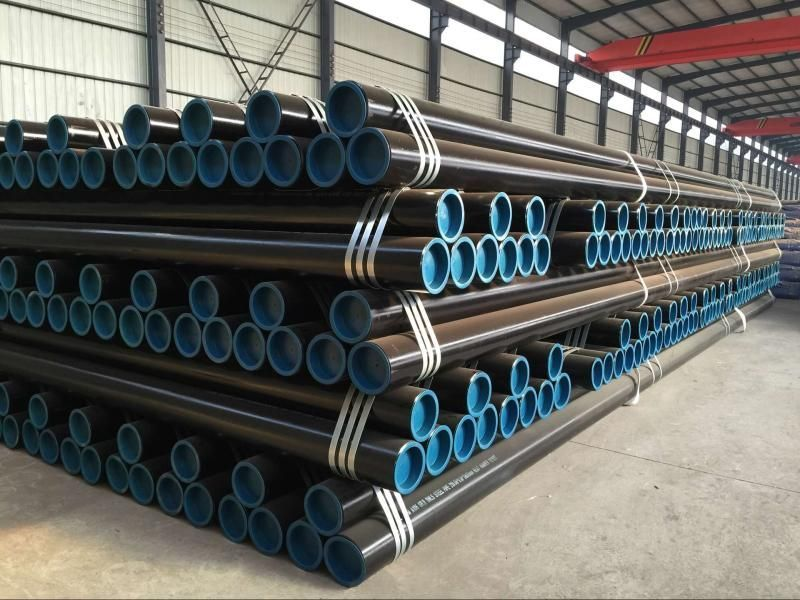

Manufacturer: Womic Steel Group

Product Type: Seamless Steel Pipe

Material Grade: ASTM A106 Gr B

Application: High-temperature and high-pressure systems, petrochemical, power generation, chemical industries

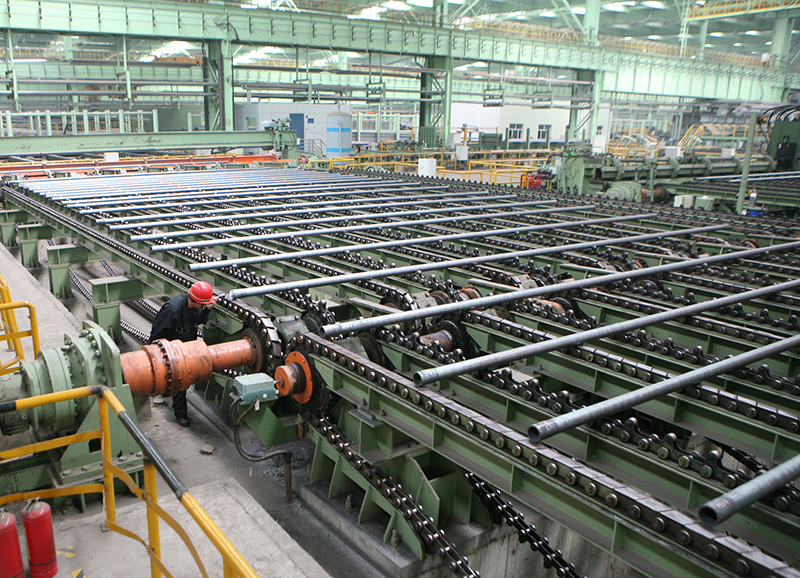

Production Process: Hot-finished or cold-drawn seamless pipe

Standard: ASTM A106 / ASME SA106

Overview

The A106 Gr B NACE PIPE is engineered for use in sour service conditions, where exposure to hydrogen sulfide (H₂S) or other corrosive elements is present. Womic Steel manufactures NACE PIPES that are designed to provide exceptional resistance to sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC) under high-pressure, high-temperature environments. These pipes meet NACE and MR 0175 standards, ensuring they are suited for critical applications in industries like oil & gas, chemical processing, petrochemical, and power generation.

Chemical Composition

The chemical composition of the A106 Gr B NACE PIPE is optimized for strength and corrosion resistance, especially in sour service environments.

|

Element |

Min % |

Max % |

|

Carbon (C) |

0.26 |

0.32 |

|

Manganese (Mn) |

0.60 |

0.90 |

|

Silicon (Si) |

0.10 |

0.35 |

|

Phosphorus (P) |

- |

0.035 |

|

Sulfur (S) |

- |

0.035 |

|

Copper (Cu) |

- |

0.40 |

|

Nickel (Ni) |

- |

0.25 |

|

Chromium (Cr) |

- |

0.30 |

|

Molybdenum (Mo) |

- |

0.12 |

This composition is designed to provide strength while ensuring the pipe can withstand sour service environments and moderate acidic conditions.

Mechanical Properties

The A106 Gr B NACE PIPE is built for high performance in extreme conditions, providing both tensile strength and elongation under pressure and temperature.

|

Property |

Value |

| Yield Strength (σ₀.₂) | 205 MPa |

| Tensile Strength (σb) | 415-550 MPa |

| Elongation (El) | ≥ 20% |

| Hardness | ≤ 85 HRB |

| Impact Toughness | ≥ 20 J at -20°C |

These mechanical properties ensure that the NACE PIPE is able to resist cracking and stress under harsh conditions such as high-pressure, high-temperature, and sour environments.

Corrosion Resistance (HIC & SSC Testing)

The A106 Gr B NACE PIPE is designed to withstand sour service conditions, and is rigorously tested for Hydrogen Induced Cracking (HIC) and Sulfide Stress Cracking (SSC) in compliance with MR 0175 standards. These tests are critical for evaluating the pipe's ability to perform in environments where hydrogen sulfide or other acidic compounds are present.

HIC (Hydrogen Induced Cracking) Testing

This test evaluates the pipe’s resistance to hydrogen-induced cracks that occur when exposed to sour environments, such as those containing hydrogen sulfide (H₂S).

SSC (Sulfide Stress Cracking) Testing

This test assesses the pipe’s ability to resist cracking under stress when exposed to hydrogen sulfide. It simulates conditions found in sour service environments like oil and gas fields.

Both of these tests ensure that the A106 Gr B NACE PIPE meets the stringent demands of industries working in sour environments, and the steel is resistant to cracking and other forms of corrosion.

Physical Properties

The A106 Gr B NACE PIPE has the following physical properties that ensure it performs reliably under extreme temperatures and pressures:

|

Property |

Value |

| Density | 7.85 g/cm³ |

| Thermal Conductivity | 45.5 W/m·K |

| Elastic Modulus | 200 GPa |

| Coefficient of Thermal Expansion | 11.5 x 10⁻⁶ /°C |

| Electrical Resistivity | 0.00000103 Ω·m |

These properties allow the pipe to maintain structural integrity even in extreme conditions and temperature variations.

Inspection and Testing

Womic Steel uses a comprehensive set of inspection methods to ensure each A106 Gr B NACE PIPE meets international standards for quality and performance. These tests include:

●Visual and Dimensional Inspection: Ensuring the pipes conform to industry specifications.

●Hydrostatic Testing: Used to check the pipe’s ability to withstand high internal pressure.

●Non-Destructive Testing (NDT): Techniques like ultrasonic testing (UT) and eddy current testing (ECT) are used to detect internal defects without damaging the pipe.

●Tensile, Impact, and Hardness Testing: To evaluate the mechanical properties under various stress conditions.

●Acid Resistance Testing: Including HIC and SSC testing, as per MR 0175 standards, to verify performance in sour service.

Womic Steel’s Manufacturing Expertise

Womic Steel’s manufacturing capabilities are built around cutting-edge production facilities and a strong commitment to quality control. With 19 years of industry experience, Womic Steel specializes in producing high-performance NACE PIPES that meet the demands of the toughest operating environments.

●Advanced Manufacturing Technology: Womic Steel operates state-of-the-art production facilities that integrate seamless pipe manufacturing, heat treatment, and advanced coating processes.

●Customization: Offering custom solutions, including different pipe grades, lengths, coatings, and heat treatments, Womic Steel tailors the NACE PIPE to specific client needs.

●Global Export: With experience in exporting to over 100 countries, Womic Steel ensures reliable and timely delivery of high-quality pipes worldwide.

Conclusion

The A106 Gr B NACE PIPE from Womic Steel combines exceptional mechanical properties, corrosion resistance, and reliability in sour service conditions. It is ideal for high-temperature, high-pressure applications in industries such as oil & gas, petrochemical, and chemical processing. Rigorous testing standards, including HIC and SSC testing per MR 0175, ensure the pipe’s durability and resistance to corrosion in challenging environments.

Womic Steel’s advanced manufacturing capabilities, commitment to quality, and extensive global export experience make it the trusted partner for NACE PIPES used in critical applications.

Choose Womic Steel Group as your reliable partner for high-quality Stainless Steel Pipes&Fittings and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Jan-04-2025