Introduction:

API 5L is a standard specification established by the American Petroleum Institute (API) for seamless and welded steel pipes used in transportation systems within the petroleum and natural gas industries. Womic Steel, a leading manufacturer of API 5L line pipes, offers a comprehensive range of products that meet various grades and specifications. This article provides a detailed comparison of the chemical composition, mechanical properties, and testing standards for different API 5L grades,both PSL1 and PSL2 across three types of pipes: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), and SMLS (Seamless).

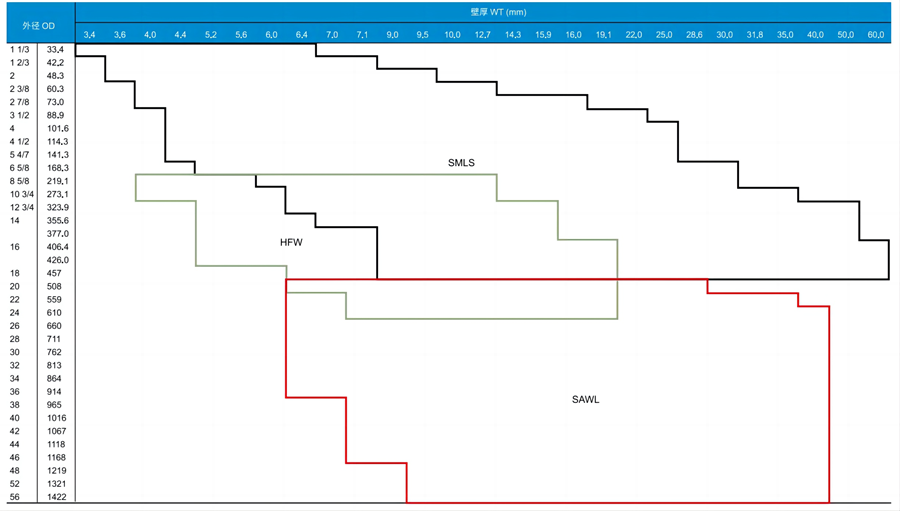

Production Capability and Range:

|

制造方法 |

钢级起 |

钢级止 |

外径起 OD Min mm |

外径止 |

壁厚起 |

壁厚止 |

生产能力 |

|

SMLS |

B |

X80Q |

33.4 |

457 |

3.4 |

60 |

200000 |

|

HFW |

B |

X80M |

219.1 |

610 |

4.0 |

19.1 |

200000 |

|

SAWL |

B |

X100M |

508 |

1422 |

6.0 |

40 |

500000 |

Tolerance of Outside Diameter

|

标准 |

外径范围 |

外径公差 |

椭圆度 |

||||

|

管体 |

管端 |

管体 |

管端 |

||||

|

无缝 |

焊管 |

无缝 |

焊管 |

无缝 |

焊管 |

||

|

API SPEC SO 3183 |

D<60.3mm |

+0.4mm/-0.8mm |

+1.6mm/-0.4mm |

||||

|

60.3mm≤D≤168.3mm |

+0.75%/-0.75% |

≤2.0% |

≤1.5% |

||||

|

168.3mm<D≤320mm |

+0.5%/-0.5% |

||||||

|

320mm<D≤426mm |

+1.6mm/-1.6mm |

||||||

|

426mm<D≤610mm |

+0.75%/-0.75% |

+3.2mm/-3.2mm |

|||||

|

610mm<D≤800mm |

+1.0%/-1.0% |

+0.5%/-0.5% |

±2.0mm |

±1.6mm |

≤1.5% |

≤1.0% |

|

|

800mm<D≤1000mm |

+4mm/-4mm |

||||||

|

1000mm<D≤1300mm |

+1.0%/-1.0% |

+4mm/-4mm |

≤15mm |

≤1.0% |

|||

|

1300mm<D≤1422mm |

+1.0%/-1.0% |

+4mm/-4mm |

≤15mm |

≤13mm |

|||

Note: D is the nominal outside diameter of the pipe.

Tolerance of Wall Thickness

|

标准 |

外径范围 |

壁厚范围 |

壁厚公差 |

壁厚公差 |

|

无缝 |

焊管 |

|||

|

API SPEC ISO 3183 |

- |

t≤4.0mm |

+0.6mm/-0.5mm |

+0.5mm/-0.5mm |

|

- |

4.0mm<t≤5.0mm |

+15%/-12.5% |

||

|

- |

5.0mm<t<15.0mm |

+10%/-10% |

||

|

- |

15.0mmst<25.0mm |

+1.5mm/-1.5mm |

||

|

- |

25.0mm≤t<30.0mm |

+3.7mm/-3.0mm |

||

|

- |

30.0mm≤t<37.0mm |

+3.7mm/-10.0% |

||

|

- |

t≥37.0mm |

+10.0%/-10.0% |

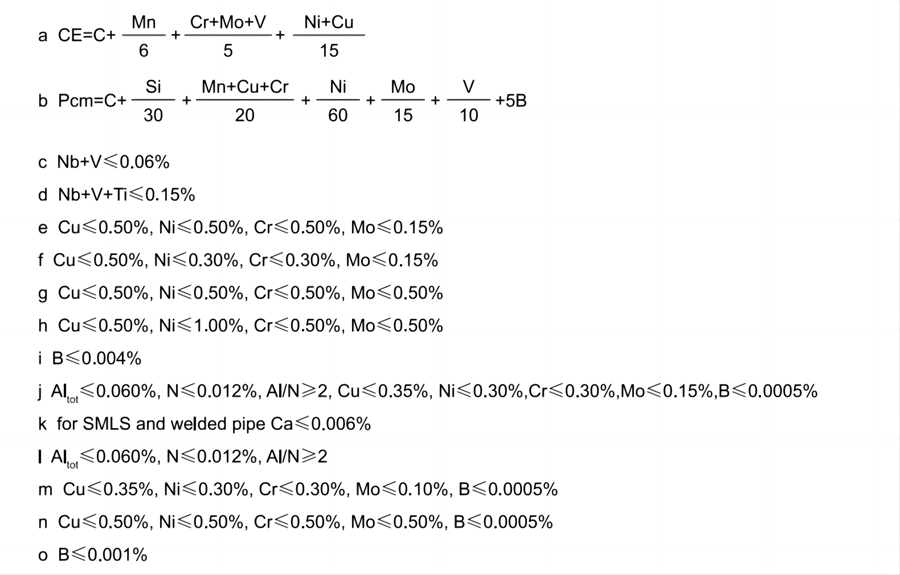

Chemical Analysis

|

标准 |

钢管种类 |

等级 |

钢级 |

C |

Si |

Mn |

P |

S |

V |

Nb |

T |

CE |

Pcm |

备注 |

|

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

|||||

|

API SPEC 5L |

无缝管 |

PSL1 |

L210 or A |

0.22 |

|

0.90 |

0.030 |

0.030 |

|

|

|

|

|

e,o |

|

L245 or B |

0.28 |

|

1.20 |

0.030 |

0.030 |

|

|

|

|

|

c,d,e,o |

|||

|

L290 or X42 |

0.28 |

|

1.30 |

0.030 |

0.030 |

|

|

|

|

|

d.e,o |

|||

|

L320 or X46 |

0.28 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L360 or X52 |

0.28 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L390 or X56 |

0.28 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L415 or X60 |

0.28 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L450 or X65 |

0.28 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d.e,o |

|||

|

L485 or X70 |

0.28 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

PSL2 |

L245N or BN |

0.24 |

0.40 |

1.20 |

0.025 |

0.015 |

|

|

0.04 |

0.43 |

0.25 |

c,f,o |

||

|

L290N or X42N |

0.24 |

0.40 |

1.20 |

0.025 |

0.015 |

0.06 |

0.05 |

0.04 |

0.43 |

0.25 |

f,o |

|||

|

L320N or X46N |

0.24 |

0.40 |

1.40 |

0.025 |

0.015 |

0.07 |

0.05 |

0.04 |

0.43 |

0.25 |

d,f,o |

|||

|

L360N or X52N |

0.24 |

0.45 |

1.40 |

0.025 |

0.015 |

0.10 |

0.05 |

0.04 |

0.43 |

0.25 |

d,f,o |

|||

|

L390N or X56N |

0.24 |

0.45 |

1.40 |

0.025 |

0.015 |

0.10 |

0.05 |

0.04 |

0.43 |

0.25 |

d,f,o |

|||

|

L415N or X60N |

0.24 |

0.45 |

1.40 |

0.025 |

0.015 |

0.10 |

0.05 |

0.04 |

As agreed |

d,g,o |

||||

|

L245Q or BQ |

0.18 |

0.45 |

1.40 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

0.43 |

0.25 |

f,o |

|||

|

L290Q or X42Q |

0.18 |

0.45 |

1.40 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

0.43 |

0.25 |

f,o |

|||

|

L320Q orX46Q |

0.18 |

0.45 |

1.40 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

0.43 |

0.25 |

f,o |

|||

|

13600 or ×52Q |

0.18 |

0.45 |

1.50 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

0.43 |

0.25 |

f,o |

|||

|

L390Q or X56Q |

0.18 |

0.45 |

1.50 |

0.025 |

0.015 |

0.07 |

0.05 |

0.04 |

0.43 |

0.25 |

d,f,o |

|||

|

L415Q or X60Q |

0.18 |

0.45 |

1.70 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,g,o |

|||

|

L450Q or X65Q |

0.18 |

0.45 |

1.70 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,g,o |

|||

|

L485Q or X70Q |

0.18 |

0.45 |

1.80 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,g,o |

|||

|

L555Q or X80Q |

0.18 |

0.45 |

1.90 |

0.025 |

0.015 |

|

|

|

As agreed |

h,i |

||||

|

酸性服 |

L245NS or BNS |

0.14 |

0.40 |

1.35 |

0.020 |

0.008 |

|

|

0.04 |

0.36 |

0.22 |

c,d,j,k |

||

|

L290NS or X42NS |

0.14 |

0.40 |

1.35 |

0.020 |

0.008 |

0.05 |

0.05 |

0.04 |

0.36 |

0.22 |

j,k |

|||

|

L320NS or X46NS |

0.14 |

0.40 |

1.40 |

0.020 |

0.008 |

0.07 |

0.05 |

0.04 |

0.38 |

0.23 |

dj,k |

|||

|

L360NS or X52NS |

0.16 |

0.45 |

1.65 |

0.020 |

0.008 |

0.10 |

0.05 |

0.04 |

0.43 |

0.25 |

d,j,k |

|||

|

L245QS or BQS |

0.14 |

0.40 |

1.35 |

0.020 |

0.008 |

0.04 |

0.04 |

0.04 |

0.34 |

0.22 |

j,k |

|||

|

L290QS or X42QS |

0.14 |

0.40 |

1.35 |

0.020 |

0.008 |

0.04 |

0.04 |

0.04 |

0.34 |

0.22 |

j,k |

|||

|

L320QS or X46QS |

0.15 |

0.45 |

1.40 |

0.020 |

0.008 |

0.05 |

0.05 |

0.04 |

0.36 |

0.23 |

j,k |

|||

|

L360QS or X52QS |

0.16 |

0.45 |

1.65 |

0.020 |

0.008 |

0.07 |

0.05 |

0.04 |

0.39 |

0.23 |

d,j,k |

|||

|

L390QS or X56QS |

0.16 |

0.45 |

1.65 |

0.020 |

0.008 |

0.07 |

0.05 |

0.04 |

0.40 |

0.24 |

d,j,k |

|||

|

L415QS or X60QS |

0.16 |

0.45 |

1.65 |

0.020 |

0.008 |

0.08 |

0.05 |

0.04 |

0.41 |

0.25 |

d.j,k |

|||

|

L450QS or X65QS |

0.16 |

0.45 |

1.65 |

0.020 |

0.008 |

0.09 |

0.05 |

0.06 |

0.42 |

0.25 |

d,j,k |

|||

|

L485QS or X70QS |

0.16 |

0.45 |

1.65 |

0.020 |

0.008 |

0.09 |

0.05 |

0.06 |

0.42 |

0.25 |

d,j,k |

|||

|

标准 |

钢管种类 |

等级 |

钢级 |

C |

Si |

Mn |

P |

S |

V |

Nb |

Ti |

CEa |

Pcm |

备注 |

|

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

|||||

|

AP|SPEC 5L |

无缝管 |

海上服 |

L245NO or BNO |

0.14 |

0.40 |

1.35 |

0.020 |

0.010 |

|

|

0.04 |

0.36 |

0.22 |

c,d,I,m |

|

L290NO or X42NO |

0.14 |

0.40 |

1.35 |

0.020 |

0.010 |

0.05 |

0.05 |

0.04 |

0.36 |

0.22 |

l,m |

|||

|

L320NO or X46NO |

0.14 |

0.40 |

1.40 |

0.020 |

0.010 |

0.07 |

0.05 |

0.04 |

0.38 |

0.23 |

d,I,m |

|||

|

L360NO or X52NO |

0.16 |

0.45 |

1.65 |

0.020 |

0.010 |

0.10 |

0.05 |

0.04 |

0.43 |

0.25 |

d,I |

|||

|

L245QO or BQO |

0.14 |

0.40 |

1.35 |

0.020 |

0.010 |

0.04 |

0.04 |

0.04 |

0.34 |

0.22 |

l,m |

|||

|

L290QO or X42Q0 |

0.14 |

0.40 |

1.35 |

0.020 |

0.010 |

0.04 |

0.04 |

0.04 |

0.34 |

0.22 |

l,m |

|||

|

L320QO or X46QO |

0.15 |

0.45 |

1.40 |

0.020 |

0.010 |

0.05 |

0.05 |

0.04 |

0.36 |

0.23 |

l,m |

|||

|

L360QO or X52QO |

0.16 |

0.45 |

1.65 |

0.020 |

0.010 |

0.07 |

0.05 |

0.04 |

0.39 |

0.23 |

d,I,n |

|||

|

L390QO or X56Q0 |

0.15 |

0.45 |

1.65 |

0.020 |

0.010 |

0.07 |

0.05 |

0.04 |

0.40 |

0.24 |

d,I,n |

|||

|

L415QO or X60QO |

0.15 |

0.45 |

1.65 |

0.020 |

0.010 |

0.08 |

0.05 |

0.04 |

0.41 |

0.25 |

d,I,n |

|||

|

L455QO or X65QO |

0.15 |

0.45 |

1.65 |

0.020 |

0.010 |

0.09 |

0.05 |

0.06 |

0.42 |

0.25 |

d,I,n |

|||

|

L485Q0 or X70Q0 |

0.17 |

0.45 |

1.75 |

0.020 |

0.010 |

0.10 |

0.05 |

0.06 |

0.42 |

0.25 |

d,l,n |

|||

|

L555QO or X80QO |

0.17 |

0.45 |

1.85 |

0.020 |

0.010 |

0.10 |

0.06 |

0.06 |

As agreed |

d,I,n |

||||

|

焊管 |

PSL1 |

L245 or B |

0.26 |

|

1.20 |

0.030 |

0.030 |

|

|

|

|

|

c.d,e,c |

|

|

L290 orX42 |

0.26 |

|

1.30 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L320 orX46 |

0.26 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L360 or X52 |

0.26 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L390 orX56 |

0.26 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L415 orX60 |

0.26 |

|

1.40 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L450 or X65 |

0.26 |

|

1.45 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

L485 or X70 |

0.26 |

|

1.65 |

0.030 |

0.030 |

|

|

|

|

|

d,e,o |

|||

|

PSL2 |

1245M or BM |

0.22 |

0.45 |

1.20 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

0.43 |

0.25 |

f,o |

||

|

L290M or X42M |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

0.43 |

0.25 |

f,o |

|||

|

L320M or X46M |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

0.43 |

0.25 |

f,o |

|||

|

L360M or X52M |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,f,o |

|||

|

L390M or X56M |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,f,o |

|||

|

L415M or X60M |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,g,o |

|||

|

L450M or X65M |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,g,o |

|||

|

L485M or X70M |

0.12 |

0.45 |

1.70 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,g,o |

|||

|

L555M or X80M |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

|

|

|

0.43 |

0.25 |

d,g,o |

|||

|

标准 |

钢管种类 |

等级 |

钢级 |

C |

Si |

Mn |

P |

S |

V |

Nb |

T |

CEa |

Pcm |

备注 |

|

max |

max |

max |

max |

max |

max |

max |

max |

max |

max |

|||||

|

API SPEC 5L |

焊管 |

酸性服 |

L245MS or BMS |

0.10 |

0.40 |

1.25 |

0.020 |

0.002 |

0.04 |

0.04 |

0.04 |

|

0.19 |

j,k |

|

L290MS or X42MS |

0.10 |

0.40 |

1.25 |

0.020 |

0.002 |

0.04 |

0.04 |

0.04 |

|

0.19 |

j,k |

|||

|

L320MS or X46MS |

0.10 |

0.45 |

1.35 |

0.020 |

0.002 |

0.05 |

0.05 |

0.04 |

|

0.20 |

j,k |

|||

|

L360MS or X52MS |

0.10 |

0.45 |

1.45 |

0.020 |

0.002 |

0.05 |

0.06 |

0.04 |

|

0.20 |

j,k |

|||

|

L390MS or X56MS |

0.10 |

0.45 |

1.45 |

0.020 |

0.002 |

0.06 |

0.08 |

0.04 |

|

0.21 |

d,j,k |

|||

|

L415MS or X60MS |

0.10 |

0.45 |

1.45 |

0.020 |

0.002 |

0.08 |

0.08 |

0.06 |

|

0.21 |

d,j,k |

|||

|

L450MS or X65MS |

0.10 |

0.45 |

1.60 |

0.020 |

0.002 |

0.10 |

0.08 |

0.06 |

|

0.22 |

d,j,k |

|||

|

L485MS or X70MS |

0.10 |

0.45 |

1.60 |

0.020 |

0.002 |

0.10 |

0.08 |

0.06 |

|

0.22 |

dj,k |

|||

|

海上服 |

L245MO or BMO |

0.12 |

0.40 |

1.25 |

0.020 |

0.010 |

0.04 |

0.04 |

0.04 |

|

0.19 |

l,m |

||

|

L290MO or X42MO |

0.12 |

0.40 |

1.35 |

0.020 |

0.010 |

0.04 |

0.04 |

0.04 |

|

0.19 |

l,m |

|||

|

L320MO or X46MO |

0.12 |

0.45 |

1.35 |

0.020 |

0.010 |

0.05 |

0.05 |

0.04 |

|

0.20 |

I,m |

|||

|

L360MO or X52MO |

0.12 |

0.45 |

1.65 |

0.020 |

0.010 |

0.05 |

0.05 |

0.04 |

|

0.20 |

d,I,n |

|||

|

L390MO or X56MO |

0.12 |

0.45 |

1.65 |

0.020 |

0.010 |

0.06 |

0.08 |

0.04 |

|

0.21 |

d,l,n |

|||

|

L415MO or X60MO |

0.12 |

0.45 |

1.65 |

0.020 |

0.010 |

0.08 |

0.08 |

0.06 |

|

0.21 |

d,I,n |

|||

|

L450MO or X65MO |

0.12 |

0.45 |

1.65 |

0.020 |

0.010 |

0.10 |

0.08 |

0.06 |

|

0.222 |

d,I,n |

|||

|

L485MO or X70MO |

0.12 |

0.45 |

1.75 |

0.020 |

0.010 |

0.10 |

0.08 |

0.06 |

|

0.22 |

d,l,n |

|||

|

L555MO or X80MO |

0.12 |

0.45 |

1.85 |

0.020 |

0.010 |

0.10 |

0.08 |

0.06 |

|

0.24 |

d,I,n |

|

标准 |

等级 |

钢级 |

|

屈服强度 |

抗拉强度 |

延伸率 |

屈强比 |

焊缝抗拉强度 |

|

API SPEC 5L |

PSL1 |

L210 or A |

Min |

210 |

335 |

a |

|

335 |

|

L245 or B |

Min |

245 |

415 |

a |

|

415 |

||

|

L290 or X42 |

Min |

290 |

415 |

a |

|

415 |

||

|

L320 or X46 |

Min |

320 |

435 |

a |

|

435 |

||

|

L360 or X52 |

Min |

360 |

460 |

a |

|

460 |

||

|

L390 or X56 |

Min |

390 |

490 |

a |

|

490 |

||

|

L415 or X60 |

Min |

415 |

520 |

a |

|

520 |

||

|

L450 or X65 |

Min |

450 |

535 |

a |

|

535 |

||

|

L485 or X70 |

Min |

485 |

570 |

a |

|

570 |

||

|

PSL2 |

L245N or BN |

Min |

245 |

415 |

a |

|

415 |

|

|

Max |

450 |

655 |

|

0.93 |

|

|||

|

L290N or X42N |

Min |

290 |

415 |

a |

|

415 |

||

|

Max |

495 |

655 |

|

0.93 |

|

|||

|

L320N or X46N |

Min |

320 |

435 |

a |

|

435 |

||

|

Max |

525 |

655 |

|

0.93 |

|

|||

|

L360N or X52N |

Min |

360 |

460 |

a |

|

460 |

||

|

Max |

530 |

760 |

|

0.93 |

|

|||

|

L390N or X56N |

Min |

390 |

490 |

a |

|

490 |

||

|

Max |

545 |

760 |

|

0.93 |

|

|||

|

L415N or X60N |

Min |

415 |

520 |

a |

|

520 |

||

|

Max |

565 |

760 |

|

0.93 |

|

|||

|

L450Q or X65Q |

Min |

450 |

535 |

a |

|

535 |

||

|

Max |

600 |

760 |

|

0.93 |

|

|||

|

L485Q or X70Q |

Min |

485 |

570 |

a |

|

570 |

||

|

Max |

635 |

760 |

|

0.93 |

|

|||

|

L555Q or X80Q |

Min |

555 |

625 |

a |

|

625 |

||

|

Max |

705 |

825 |

|

0.93 |

|

|||

|

L625M or X90M |

Min |

625 |

695 |

a |

|

695 |

||

|

Max |

775 |

915 |

|

0.95 |

|

|||

|

L690M or X100M |

Min |

690 |

760 |

a |

|

760 |

||

|

Max |

840 |

990 |

|

0.97 |

|

|||

|

L830M or X120M |

Min |

830 |

915 |

a |

|

915 |

||

|

Max |

1050 |

1145 |

|

0.99 |

|

标准 |

等级 |

钢级 |

|

屈服强度 |

抗拉强度 |

延伸率 |

屈强比 |

焊缝抗拉强度 |

|

API SPEC 5L |

酸性服 |

L245NS or BNS |

Min |

245 |

415 |

a |

|

415 |

|

Max |

450 |

655 |

|

0.93 |

|

|||

|

L290NS or X42NS |

Min |

290 |

415 |

a |

|

415 |

||

|

Max |

495 |

655 |

|

0.93 |

|

|||

|

L320NS or X46NS |

Min |

320 |

435 |

a |

|

435 |

||

|

Max |

525 |

655 |

|

0.93 |

|

|||

|

L360NS or X52NS |

Min |

360 |

460 |

a |

|

460 |

||

|

Max |

530 |

760 |

|

0.93 |

|

|||

|

L390QS or X56QS |

Min |

390 |

490 |

a |

|

490 |

||

|

Max |

545 |

760 |

|

0.93 |

|

|||

|

L415QS or X60QS |

Min |

415 |

520 |

a |

|

520 |

||

|

Max |

565 |

760 |

|

0.93 |

|

|||

|

L450QS or X65QS |

Min |

450 |

535 |

a |

|

535 |

||

|

Max |

600 |

760 |

|

0.93 |

|

|||

|

L485QS or X70QS |

Min |

485 |

570 |

a |

|

570 |

||

|

Max |

635 |

760 |

|

0.93 |

|

|||

|

海上服 |

L245NO or BNO |

Min |

245 |

415 |

a |

- |

415 |

|

|

Max |

450 |

655 |

|

0.93 |

|

|||

|

L290NO or X42NO |

Min |

290 |

415 |

a |

|

415 |

||

|

Max |

495 |

655 |

|

0.93 |

|

|||

|

L320NO or X46NO |

Min |

320 |

435 |

a |

|

435 |

||

|

Max |

520 |

655 |

|

0.93 |

|

|||

|

L360NO or X52NO |

Min |

360 |

460 |

a |

|

460 |

||

|

Max |

525 |

760 |

|

0.93 |

|

|||

|

L390QO or X56QO |

Min |

390 |

490 |

a |

|

490 |

||

|

Max |

540 |

760 |

|

0.93 |

|

|||

|

L415QO or X60QO |

Min |

415 |

520 |

a |

- |

520 |

||

|

Max |

565 |

760 |

|

0.93 |

|

|||

|

L450QO or X65QO |

Min |

450 |

535 |

a |

- |

535 |

||

|

Max |

570 |

760 |

|

0.93 |

|

|||

|

L485Q0 or X70Q0 |

Min |

485 |

570 |

a |

|

570 |

||

|

Max |

605 |

760 |

|

0.93 |

|

|||

|

L555QO or X80QO |

Min |

555 |

625 |

a |

|

625 |

||

|

Max |

675 |

825 |

|

0.93 |

Note: a: The minimum elongation using the following equation: A1=1940*A0.2/U0.9

|

钢级 |

管体最小横向冲击功(1(2)(3) |

焊缝最小横向冲击功(1(2(3) |

|||||

|

D≤508 |

508mm<D |

762mm<D |

914mm<D |

1219mm<D |

D<1422mm |

D=1422mm |

|

|

≤L415 or X60 |

27(20) |

27(20) |

40(30) |

40(30) |

40(30) |

27(20) |

40(30) |

|

>L415 or X60 |

27(20) |

27(20) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

|

>L450 or X65 |

27(20) |

27(20) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

|

>L485 or X70 |

40(30) |

40(30) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

Note: (1)The values in the table be suitable for the full size standard sample.

(2) The value inside bracket is the minimum single value,outside bracket is the average value.

(3)Test Temperature : 0°C.

Testing Standards:

API 5L line pipes manufactured by Womic Steel undergo rigorous testing to ensure they meet the highest quality standards. The testing standards include:

Chemical Analysis:

The chemical composition of the steel is analyzed to verify that it meets the requirements of the API 5L specification.

Chemical analysis is conducted using a direct-reading spectrometer to accurately determine the elemental composition of the steel.

Mechanical Testing:

Mechanical properties such as yield strength, tensile strength, and elongation are tested to ensure they meet the specified requirements.

Mechanical testing is performed using a 60-ton tensile testing machine to measure the strength and ductility of the steel.

Hydrostatic Testing:

Hydrostatic testing is conducted to check the integrity of the pipe and ensure it can withstand the pressure requirements of its intended application.

Pipes are filled with water and subjected to pressure, with the test duration and pressure levels specified by API 5L standards.

Non-Destructive Testing (NDT):

NDT methods such as ultrasonic testing (UT) and magnetic particle testing (MT) are used to detect any defects or discontinuities in the pipe.

UT is used to identify internal defects, while MT is used to detect surface defects.

Impact Testing:

Impact testing is performed to assess the toughness of the steel at low temperatures.

The Charpy impact test is commonly used to measure the impact energy absorbed by the steel.

Hardness Testing:

Hardness testing is conducted to evaluate the hardness of the steel, which can indicate its strength and suitability for specific applications.

The Rockwell hardness test is often used to measure the hardness of the steel.

Microstructure Examination:

Microstructure examination is performed to assess the grain structure and overall quality of the steel.

A metallurgical microscope is used to examine the microstructure of the steel and identify any abnormalities.

By adhering to these rigorous testing standards, Womic Steel ensures that its API 5L line pipes meet the highest quality requirements and provide reliable performance in various industrial applications.

Production Process:

1. Seamless Steel Pipes:

- Raw Material Selection: High-quality round steel billets are selected for the production of seamless steel pipes.

- Heating and Piercing: The billets are heated to a high temperature and then pierced to create a hollow shell.

- Rolling and Sizing: The pierced shell is then rolled and stretched to the desired diameter and thickness.

- Heat Treatment: The pipes are subjected to heat treatment processes such as annealing or normalizing to improve their mechanical properties.

- Finishing: The pipes undergo finishing processes such as straightening, cutting, and inspection.

- Testing: The pipes undergo various tests, including hydrostatic testing, ultrasonic testing, and eddy current testing, to ensure their quality.

- Surface Treatment: The pipes may be coated or treated to prevent corrosion and improve their appearance.

- Packaging and Shipping: The pipes are carefully packaged and shipped to customers.

2. LSAW (Longitudinal Submerged Arc Welding) Steel Pipes:

- Plate Preparation: High-quality steel plates are prepared for the production of LSAW pipes.

- Forming: The plates are formed into a "U" shape using a pre-bending machine.

- Welding: The "U" shaped plates are then welded together using the submerged arc welding process.

- Expansion: The welded seam is expanded to the desired diameter using an internal or external expanding machine.

- Inspection: The pipes undergo inspection for defects and dimensional accuracy.

- Ultrasonic Testing: The pipes are subjected to ultrasonic testing to detect any internal defects.

- Beveling: The pipe ends are beveled for welding.

- Coating and Marking: The pipes may be coated and marked according to customer requirements.

- Packaging and Shipping: The pipes are packaged and shipped to customers.

3. HFW (High-Frequency Welding) Steel Pipes:

- Coil Preparation: Steel coils are prepared for the production of HFW pipes.

- Forming and Welding: The coils are formed into a cylindrical shape and then welded using high-frequency welding.

- Weld Seam Heating: The weld seam is heated to the welding temperature using high-frequency induction heating.

- Sizing: The welded pipe is sized to the required diameter and thickness.

- Cutting and Beveling: The pipe is cut to the desired length and the ends are beveled for welding.

- Inspection: The pipes undergo inspection for defects and dimensional accuracy.

- Hydrostatic Testing: The pipes are tested for strength and leaks using hydrostatic testing.

- Coating and Marking: The pipes are coated and marked according to customer requirements.

- Packaging and Shipping: The pipes are packaged and shipped to customers.

These detailed production processes ensure the high quality and reliability of seamless, LSAW, and HFW steel pipes manufactured by Womic Steel, meeting the stringent requirements of various industries.

Surface Treatment:

The surface treatment of pipeline steel is crucial for improving its corrosion resistance and service life. Womic Steel employs various surface treatment methods depends on different requirements from clients, including:

1. Hot-dip Galvanizing: The steel pipe is immersed in molten zinc to form a zinc-iron alloy protective layer, enhancing its corrosion resistance. Hot-dip galvanizing is suitable for conventional and low-pressure pipelines.

2. Anti-corrosion Coatings: Common anti-corrosion coatings include epoxy coatings, polyethylene coatings, and polyurethane coatings. These coatings effectively prevent oxidation and corrosion on the surface of the steel pipe, prolonging its service life.

3. Sandblasting: High-speed abrasive blasting is used to clean the steel pipe, removing rust and impurities from the surface, providing a good foundation for subsequent coating treatments.

4. Coating Treatment: The steel pipe's surface can be coated with anti-corrosive paints, asphalt paints, and other coatings to enhance its corrosion resistance, suitable for underground pipelines and pipelines in marine environments.

These surface treatment methods effectively protect pipeline steel from corrosion and damage, ensuring its reliability and durability in various harsh environments.

Packaging and Transportation:

Womic Steel ensures the safe packaging and reliable transportation of pipeline steel, offering flexible options to meet diverse customer needs:

1. Bulk Cargo: For large orders, pipeline steel can be shipped in bulk using specialized bulk carriers. The steel is loaded directly into the ship's hold without packaging, suitable for cost-effective transportation of large quantities.

2. LCL (Less than Container Load): For smaller orders, pipeline steel can be shipped as LCL cargo, where multiple smaller orders are consolidated into a single container. This method is cost-effective for smaller quantities and offers more flexible delivery schedules.

3. FCL (Full Container Load): Customers can opt for FCL shipping, where a full container is dedicated to their order. This method provides faster transit times and reduces the risk of damage during handling.

4. Air Freight: For urgent orders, air freight is available for rapid delivery. While more expensive than sea freight, air freight offers fast and reliable transportation for time-sensitive shipments.

Womic Steel ensures that all shipments are securely packaged to prevent damage during transportation. The steel is typically wrapped in protective materials and secured in containers or on pallets to ensure stability during transit. Additionally, the company works closely with reputable shipping partners to ensure timely delivery and efficient logistics management.

Application Scenarios:

API 5L line pipes produced by Womic Steel are widely used in the petroleum and natural gas industries for the transportation of oil, gas, and other fluids. They are also used in various other industries such as chemical processing, power generation, and construction.

Conclusion:

Womic Steel is a trusted manufacturer of API 5L line pipes, offering high-quality products that meet the stringent requirements of the petroleum and natural gas industries. With a focus on quality, reliability, and customer satisfaction, Womic Steel continues to be a preferred choice for customers worldwide.

Post time: Mar-22-2024