1. Overview

ASTM A131/A131M is the specification for structural steel for ships. Grade AH/DH 32 are high-strength, low-alloy steels used primarily in shipbuilding and marine structures.

2. Chemical Composition

The chemical composition requirements for ASTM A131 Grade AH32 and DH32 are as follows:

- Carbon (C): Maximum 0.18%

- Manganese (Mn): 0.90 - 1.60%

- Phosphorus (P): Maximum 0.035%

- Sulfur (S): Maximum 0.035%

- Silicon (Si): 0.10 - 0.50%

- Aluminum (Al): Minimum 0.015%

- Copper (Cu): Maximum 0.35%

- Nickel (Ni): Maximum 0.40%

- Chromium (Cr): Maximum 0.20%

- Molybdenum (Mo): Maximum 0.08%

- Vanadium (V): Maximum 0.05%

- Niobium (Nb): Maximum 0.02%

3. Mechanical Properties

The mechanical property requirements for ASTM A131 Grade AH32 and DH32 are as follows:

- Yield Strength (min): 315 MPa (45 ksi)

- Tensile Strength: 440 - 590 MPa (64 - 85 ksi)

- Elongation (min): 22% in 200 mm, 19% in 50 mm

4. Impact Properties

- Impact Test Temperature: -20°C

- Impact Energy (min): 34 J

5. Carbon Equivalent

The Carbon Equivalent (CE) is calculated to assess the weldability of steel. The formula used is:

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

For ASTM A131 Grade AH32 and DH32, the typical CE values are below 0.40.

6. Available Dimensions

ASTM A131 Grade AH32 and DH32 plates are available in a wide range of dimensions. Common sizes include:

- Thickness: 4 mm to 200 mm

- Width: 1200 mm to 4000 mm

- Length: 3000 mm to 18000 mm

7. Production Process

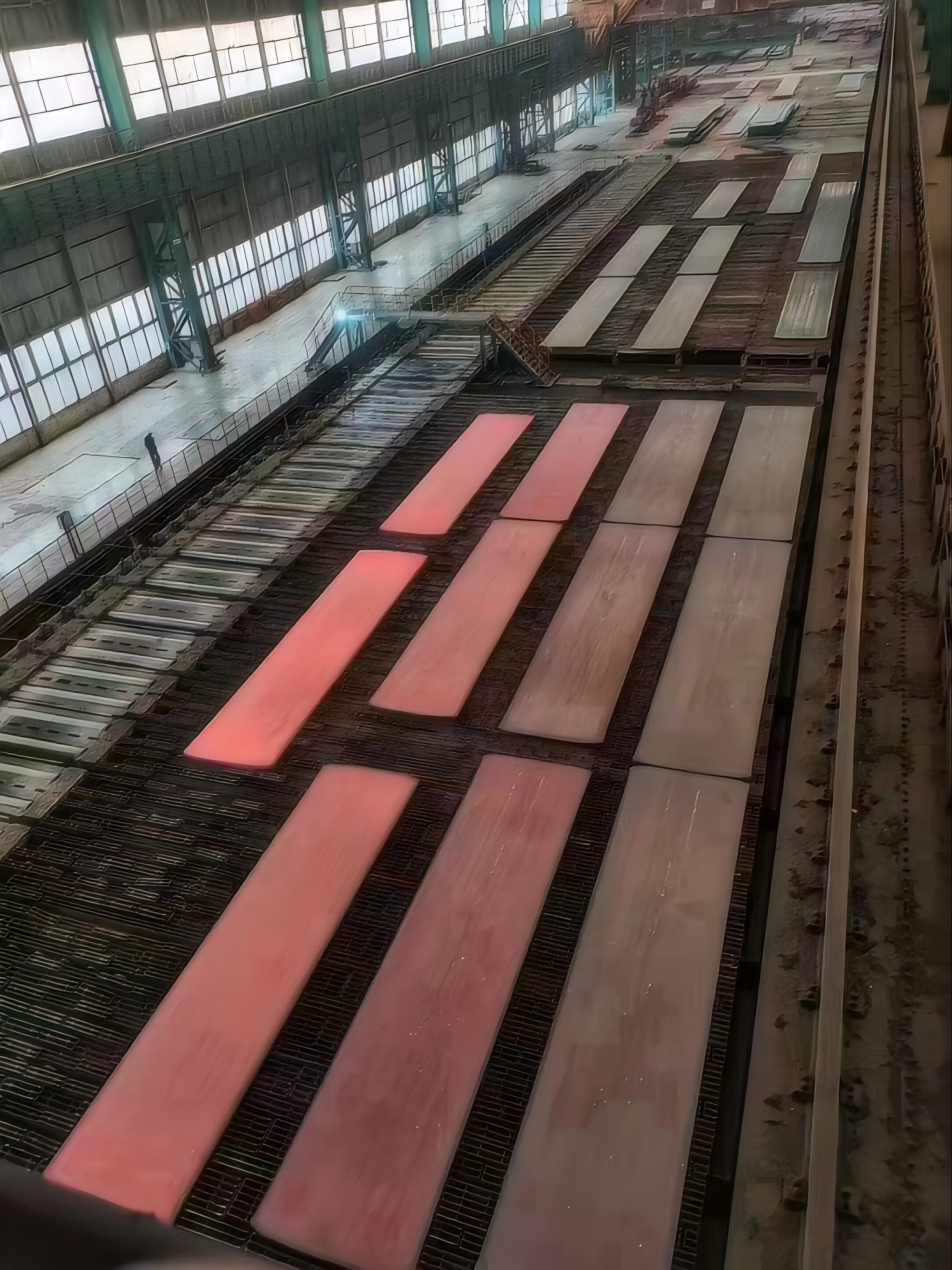

Melting: Electric Arc Furnace (EAF) or Basic Oxygen Furnace (BOF).

Hot Rolling: The steel is hot rolled in plate mills.

Heat Treatment: Controlled rolling followed by controlled cooling.

8. Surface Treatment

Shot Blasting: Removes mill scale and surface impurities.

Coating: Painted or coated with anti-corrosion oil.

9. Inspection Requirements

Ultrasonic Testing: To detect internal flaws.

Visual Inspection: For surface defects.

Dimensional Inspection: Ensures adherence to specified dimensions.

Mechanical Testing: Tensile, impact, and bend tests are performed to verify mechanical properties.

10. Application Scenarios

Shipbuilding: Used for the construction of the hull, deck, and other critical structures.

Marine Structures: Suitable for offshore platforms and other marine applications.

Womic Steel's Development History and Project Experience

Womic Steel has been a prominent player in the steel industry for decades, earning a reputation for excellence and innovation. Our journey began over 30 years ago, and since then, we have expanded our production capabilities, adopted advanced technologies, and committed to the highest standards of quality.

Key Milestones

1980s: Establishment of Womic Steel, focusing on high-quality steel production.

1990s: Introduction of advanced manufacturing technologies and expansion of production facilities.

2000s: Achieved ISO, CE, and API certifications, reinforcing our commitment to quality.

2010s: Expanded our product range to include a variety of steel grades and forms, including pipes, plates, bars, and wires.

2020s: Strengthened our global presence through strategic partnerships and export initiatives.

Project Experience

Womic Steel has supplied materials for numerous high-profile projects around the world, including:

1. Marine Engineering Projects: Provided high-strength steel plates for the construction of offshore platforms and ship hulls.

2. Infrastructure Developments: Supplied structural steel for bridges, tunnels, and other critical infrastructure.

3. Industrial Applications: Delivered customized steel solutions for manufacturing plants, refineries, and power stations.

4. Renewable Energy: Supported the construction of wind turbine towers and other renewable energy projects with our high-strength steel products.

Womic Steel's Production, Inspection, and Logistics Advantages

1. Advanced Production Facilities

Womic Steel is equipped with state-of-the-art manufacturing facilities that allow for precise control of chemical composition and mechanical properties. Our production lines are capable of producing a wide range of steel products, including plates, pipes, bars, and wires, with customizable sizes and thicknesses.

2. Stringent Quality Control

Quality is at the core of Womic Steel's operations. We adhere to strict quality control measures to ensure our products meet the highest standards. Our quality assurance process includes:

Chemical Analysis: Verifying the chemical composition of raw materials and finished products.

Mechanical Testing: Conducting tensile, impact, and hardness tests to ensure mechanical properties meet specifications.

Non-Destructive Testing: Utilizing ultrasonic and radiographic testing to detect internal flaws and ensure structural integrity.

3. Comprehensive Inspection Services

Womic Steel offers comprehensive inspection services to guarantee product quality. Our inspection services include:

Third-Party Inspection: We accommodate third-party inspection services to provide independent verification of product quality.

In-House Inspection: Our in-house inspection team performs thorough checks at every stage of the production process to ensure compliance with industry standards.

4.Efficient Logistics and Transportation

Womic Steel has a robust logistics network that ensures timely delivery of products worldwide. Our logistics and transportation advantages include:

Strategic Location: Proximity to major ports and transportation hubs facilitates efficient shipping and handling.

Secure Packaging: Products are securely packaged to prevent damage during transit. We offer customized packaging solutions to meet specific customer requirements.

Global Reach: Our extensive logistics network allows us to deliver products to customers around the globe, ensuring timely and reliable supply.

Post time: Jul-27-2024