Introduction

ASTM A179 steel pipe is a seamless cold-drawn low-carbon steel heat-exchanger and condenser tube. Womic Steel is a leading manufacturer of ASTM A179 steel pipes, known for its high-quality products and reliable performance. This article provides a detailed overview of the production dimensions, production process, surface treatment, packaging and transportation methods, testing standards, chemical composition, mechanical properties, inspection requirements, and application scenarios of ASTM A179 steel pipes by Womic Steel.

Production Dimensions

ASTM A179 steel pipes produced by Womic Steel have the following dimensions:

- Outer Diameter: 1/8 inch to 3 inch (3.2mm to 76.2mm)

- Wall Thickness: 0.015 inch to 0.500 inch (0.4mm to 12.7mm)

- Length: 1m to 12m (customizable)

Production Process

Womic Steel uses a cold-drawn seamless manufacturing process to produce ASTM A179 steel pipes. This process involves:

1. Selecting high-quality raw materials

2. Heating the raw materials to a suitable temperature

3. Piercing the heated billet to form a hollow tube

4. Cold-drawing the tube to the desired dimensions

5. Annealing the tube to improve its mechanical properties

6. Cutting and finishing the tube to the required length and surface finish

Surface Treatment

ASTM A179 steel pipes produced by Womic Steel can be supplied with various surface finishes, including:

- Black Phosphating

- Oiled

- Pickled and Oiled

- Bright Annealed

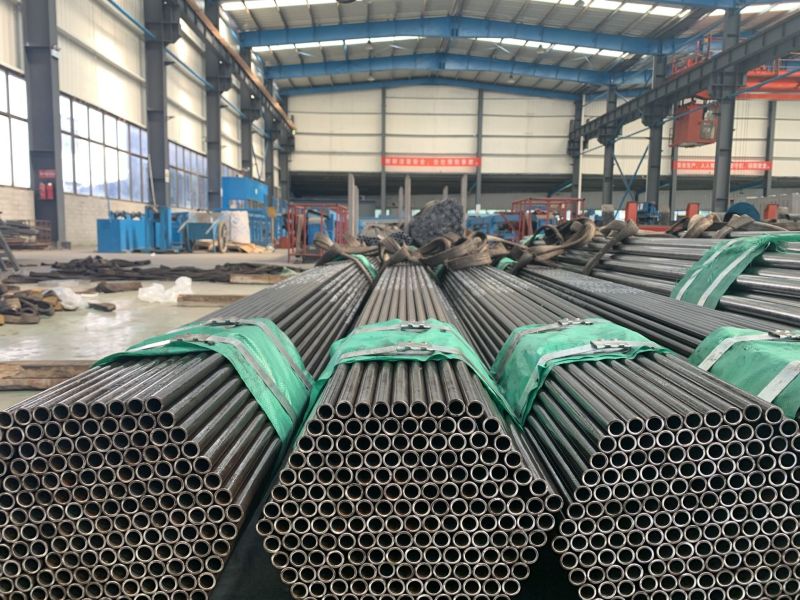

Packaging and Transportation

ASTM A179 steel pipes produced by Womic Steel are typically packaged in bundles or wooden cases for transportation. Special packaging requirements can be accommodated upon request.

Testing Standards

ASTM A179 steel pipes produced by Womic Steel are tested according to the following standards:

- ASTM A450/A450M: Standard Specification for General Requirements for Carbon and Low Alloy Steel Tubes

- ASTM A179/A179M: Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes

Chemical Composition

The chemical composition of ASTM A179 steel pipes produced by Womic Steel is as follows:

- Carbon (C): 0.06-0.18%

- Manganese (Mn): 0.27-0.63%

- Phosphorus (P): 0.035% max

- Sulfur (S): 0.035% max

Mechanical Properties

The mechanical properties of ASTM A179 steel pipes produced by Womic Steel are as follows:

- Tensile Strength: 325 MPa min

- Yield Strength: 180 MPa min

- Elongation: 35% min

Inspection Requirements

ASTM A179 steel pipes produced by Womic Steel are subject to stringent inspection requirements, including visual inspection, dimensional inspection, mechanical testing, hydrostatic testing, and non-destructive testing, to ensure their quality and performance.

Application Scenarios

ASTM A179 steel pipes produced by Womic Steel are widely used in various industries, including:

- Power generation

- Petrochemical

- Chemical processing

- Oil and gas

- Pharmaceutical

- Food processing

Womic Steel's Production Strengths and Advantages

Womic Steel has a strong production capability and several advantages, including:

- Advanced Production Equipment: Womic Steel is equipped with advanced production equipment, ensuring high-quality and efficient production of ASTM A179 steel pipes.

- Strict Quality Control: Womic Steel implements strict quality control measures at every stage of the production process to ensure that ASTM A179 steel pipes meet the highest quality standards.

- Customization Options: Womic Steel offers customization options for ASTM A179 steel pipes, allowing customers to specify their requirements for dimensions, materials, and other parameters.

- Competitive Pricing: Womic Steel offers competitive pricing for ASTM A179 steel pipes, making them a cost-effective solution for various industrial applications.

Conclusion

ASTM A179 steel pipes produced by Womic Steel are high-quality, reliable components used in a wide range of industrial applications. With their superior production capabilities, strict quality control measures, and competitive pricing, Womic Steel is a trusted manufacturer of ASTM A179 steel pipes, meeting the needs of customers in various industries.

Post time: Mar-18-2024