In the vast landscape of metal materials, ASTM TP310S stainless steel pipes and seamless pipes stand out with their unique performance advantages and wide application scope. They have become indispensable in industrial manufacturing and high-end equipment, offering excellent heat resistance and corrosion protection. This article delves into the unique allure of ASTM TP310S stainless steel pipes and seamless pipes by examining their material properties, production processes, application fields, market prospects, and maintenance tips.

ASTM TP310S Stainless Steel Pipe & Seamless Pipe Standards

Standards executed include:

●ASTM A312

●ASTM A790

●ASME SA213

●ASME SA249

●ASME SA789

●GB/T 14976

The TP310S stainless steel pipes are typically manufactured using cold-rolled seamless steel pipe, cold-drawn seamless steel pipe, and are delivered in a heat-treated and pickled condition.

Chemical Composition of TP310S Stainless Steel Pipe (%)

●Nickel (Ni): 19.00~22.00

●Chromium (Cr): 24.00~26.00

●Silicon (Si): ≤1.50

●Manganese (Mn): ≤2.00

●Carbon (C): ≤0.08

●Sulfur (S): ≤0.030

●Phosphorus (P): ≤0.045

Material Properties: A Perfect Blend of Heat Resistance and Corrosion Resistance

ASTM TP310S stainless steel, also known as 25Cr-20Ni stainless steel, is a typical austenitic stainless steel known for its high-temperature stability and excellent oxidation resistance. In continuous working environments, TP310S stainless steel can maintain stable physical and chemical properties at temperatures as high as 1200°C, which far surpasses the limits of conventional stainless steel. Additionally, it boasts superior corrosion resistance, protecting against a variety of acids, alkalis, and chlorides, making it a reliable choice for extreme operating conditions.

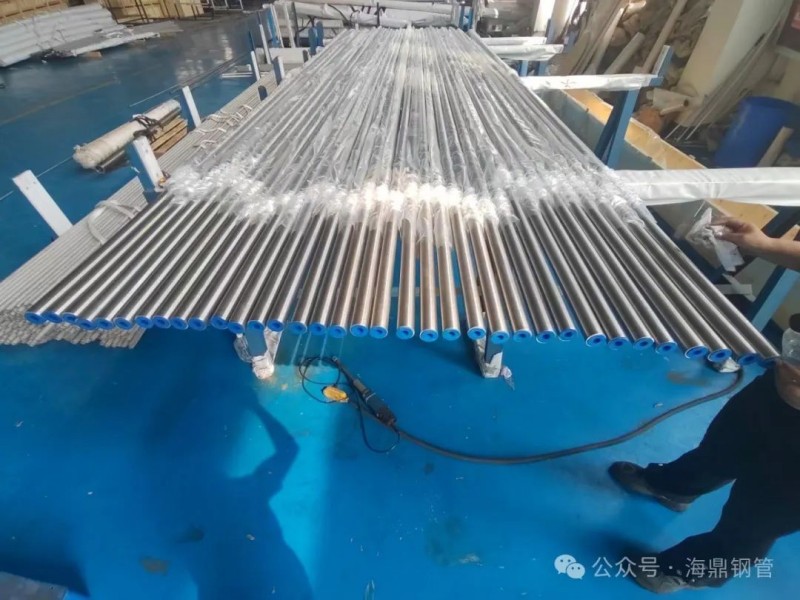

Production Process: Mastery in Craftsmanship for Outstanding Quality

The production of ASTM TP310S stainless steel pipes and seamless pipes involves an intricate combination of precision machining, heat treatment, and surface treatment. Seamless pipe production is especially meticulous, often utilizing advanced methods such as hot-rolled piercing or cold-rolled extrusion to ensure smooth inner and outer walls and precise dimensions.

At Womic Steel, the manufacturing process begins with the selection of high-grade raw materials, ensuring the optimal blend of elements like chromium and nickel to achieve the desired strength and durability. During the heat treatment phase, strict temperature control and precise time management are applied to refine the grain structure of the material, enhancing its mechanical properties and heat resistance. Additionally, the surface is treated through pickling, polishing, or passivation to further improve the pipe’s corrosion resistance and aesthetics.

Testing and Inspection: Ensuring Consistent Quality

To guarantee that TP310S stainless steel pipes meet rigorous industry standards, Womic Steel employs a comprehensive testing regime. This includes:

●Chemical Composition Analysis: Ensuring the right balance of elements like Cr and Ni to deliver the required performance.

●Mechanical Testing: Tensile strength, yield strength, and elongation are thoroughly tested to meet ASTM standards.

●Hydrostatic Testing: Pipes undergo high-pressure testing to ensure their durability and resistance to leaks under operating conditions.

●Non-Destructive Testing (NDT): Ultrasonic and eddy current testing ensure there are no internal defects or inclusions in the material.

●Surface Inspection: A visual inspection combined with surface roughness measurement ensures a flawless finish.

Application Fields: Wide Coverage Supporting Industry Growth

The application of ASTM TP310S stainless steel pipes and seamless pipes is extensive, covering nearly every industrial field that requires high-temperature, high-pressure, and corrosion-resistant environments. In the petrochemical industry, they are used to manufacture high-temperature and high-pressure reactors, heat exchangers, and pipeline systems. In the energy sector, particularly in nuclear power plants and thermal power plants, TP310S stainless steel pipes, due to their excellent heat resistance, are the material of choice for steam pipelines and superheater piping. Additionally, they play a key role in aerospace, food processing, and pharmaceuticals, offering strong support for the development of these industries.

Market Prospects: Growing Demand Driven by Innovation

As global industrialization continues and the new energy industry rapidly develops, the demand for high-performance, reliable metal materials is on the rise. As a standout material, ASTM TP310S stainless steel pipe and seamless pipes have a bright market outlook. On one hand, the modernization of traditional industries and the construction of new projects will continue to drive demand for these materials. On the other hand, with the constant emergence of new materials and advancements in process technology, the performance of TP310S stainless steel will continue to improve, and its application areas will expand. Particularly in the fields of energy conservation, emission reduction, and environmental protection, TP310S stainless steel’s advantages will become increasingly apparent, contributing to sustainable industrial development.

Womic Steel’s Manufacturing Strength: A Leader in High-Performance Metal Solutions

As a leading manufacturer of stainless steel and alloy pipes, Womic Steel stands out in the industry due to its cutting-edge production facilities and strict adherence to international standards. Our production capacity is second to none, capable of manufacturing stainless steel pipes ranging from 1/2 inch to 96 inches, with customizable sizes, thicknesses, and lengths to meet client specifications.

Womic Steel is known for:

●Advanced Equipment: We use state-of-the-art machinery for both hot-rolled and cold-drawn processes, ensuring the highest quality in every pipe we produce.

●International Certifications: Our facilities are ISO, CE, and API certified, ensuring compliance with global standards and access to markets worldwide.

●Custom Solutions: We offer tailored products and services, including third-party inspections, special packaging, and bundling options, which guarantee that our pipes meet both quality standards and customer-specific requirements.

●Innovative R&D: Our research and development team continuously improves product performance, with a focus on enhancing heat resistance, corrosion resistance, and mechanical strength.

●Environmental Commitment: As part of our dedication to green manufacturing, we implement energy-efficient processes and reduce waste, contributing to global sustainability goals.

Maintenance Tips: Effective Management to Extend Service Life

While ASTM TP310S stainless steel pipes and seamless pipes offer exceptional performance, they still require proper management and maintenance to ensure long-term stable operation. Regularly inspect the surface of the pipes for signs of corrosion, cracking, or other defects, and address them promptly. Follow the operational guidelines to avoid over-temperature and over-pressure conditions that could damage the pipes. Periodic cleaning and maintenance will help maintain the cleanliness and smoothness of the inner and outer walls, reducing the impact of corrosive substances on the pipes.

By adopting a scientific management and maintenance approach, companies can extend the service life of ASTM TP310S stainless steel pipes and reduce operational costs in the long run.

Conclusion

ASTM TP310S stainless steel pipes and seamless pipes are integral components in modern industry, offering unique material properties, sophisticated production processes, wide-ranging applications, promising market prospects, and efficient maintenance strategies. With Womic Steel’s unparalleled manufacturing expertise and commitment to quality, these pipes will continue to play a crucial role in industrial development, driving progress in various sectors and contributing to a sustainable future.

Post time: Oct-17-2024