Womic Copper, a division of Womic Steel, is a professional manufacturer and global supplier of oxygen-free copper tubing, delivering top-grade C10100 (OFE) copper tubes with guaranteed purity, electrical conductivity, and mechanical performance. Our production is strictly in accordance with ASTM B188 and B601, ensuring that every tube meets international standards for high-performance industrial use.

With an industry-leading ability to control oxygen levels to as low as 5 ppm, and advanced refining technology to reduce total impurities below 40 ppm, Womic Copper is your go-to manufacturer for precision copper tubes in power substations, vacuum applications, electronics, and cleanroom systems.

1. Product Overview – C10100 Oxygen-Free Copper

UNS Number: C10100

Designation: OFE Copper (Oxygen-Free Electronic Copper)

Purity: ≥ 99.99% Cu

Oxygen Content: ≤ 5 ppm (Womic can control between 3–5 ppm)

Electrical Conductivity: ≥ 101% IACS

Standards:

●ASTM B188 – Seamless Copper Tube for Air Conditioning and Refrigeration

●ASTM B68 / B75 – Seamless Copper Tube for General Engineering

●ASTM B280 – Refrigeration Grade

●EN 12735-1 – Copper Tubes for Air Conditioning and Refrigeration

● GB/T 1527 – Seamless Copper Tubes

● JIS H3300 – Japanese Standard for Copper and Copper Alloy Tubes

Womic C10100 copper tubing is oxygen-free, vacuum-grade, and provides maximum conductivity, corrosion resistance, and ductility, making it ideal for high-end electrical and thermal systems.

Dimensional Tolerances:

Straightness Tolerance: ≤ 13 mm over full length

Length Tolerance: ± 13 mm

Surface Condition: Clean and free from any dirt or surface defects that could interfere with intended applications.

2. Chemical Composition – Ultra-Pure OFE Copper (C10100)

Womic Copper ensures that every C10100 copper tube exceeds 99.99% copper purity, with oxygen content strictly controlled at ≤ 0.0005% (5 ppm). The full impurity specification is as follows:

|

Element |

Max PPM |

Element |

Max PPM |

|

Antimony (Sb) |

4 |

Lead (Pb) |

5 |

|

Arsenic (As) |

5 |

Manganese (Mn) |

0.5 |

|

Bismuth (Bi) |

1 |

Nickel (Ni) |

10 |

|

Cadmium (Cd) |

1 |

Phosphorus (P) |

3 |

|

Iron (Fe) |

10 |

Selenium (Se) |

3 |

|

Silver (Ag) |

25 |

Sulfur (S) |

15 |

|

Tellurium (Te) |

2 |

Tin (Sn) |

2 |

|

Zinc (Zn) |

1 |

Oxygen (O) |

0.0005 |

Total Impurity Limit:

Antimony + Selenium + Arsenic + Tellurium+ Bismuth + Tin + Manganese ................. Max 40 ppm

Copper Content = 100% – Total Impurities. Total impurities are the sum of silver, sulphur, lead, tin, bismuth, arsenic, antimony, iron, nickel, mercury, zinc, phosphorus, selenium, tellurium, manganese, cadmium and oxygen.

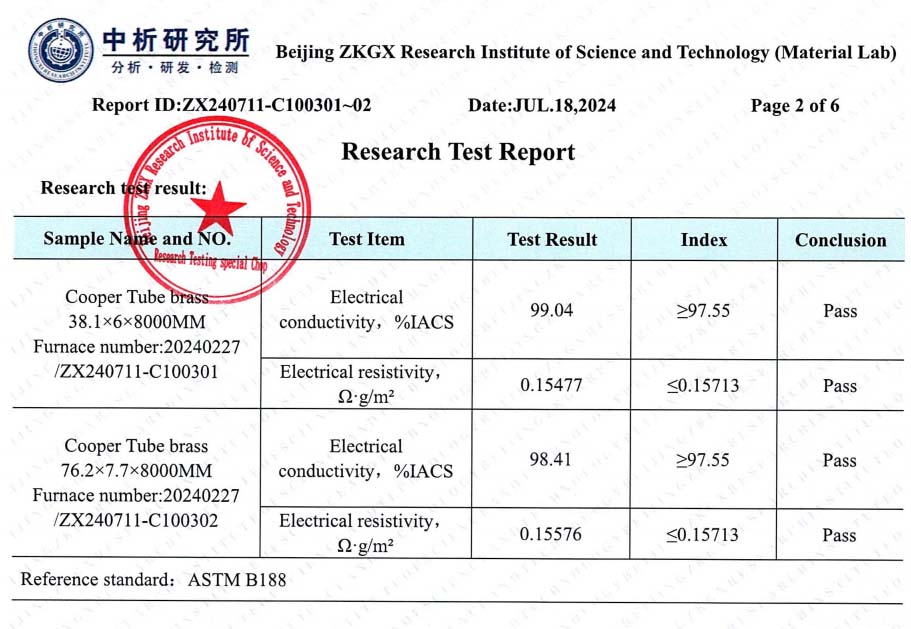

3. Electrical & Mechanical Properties

Our C10100 oxygen-free copper tubes are engineered for optimal conductivity and strength, with consistent performance across production batches.

|

Property |

Typical Value |

|

Electrical Conductivity |

≥ 101% IACS |

|

Electrical Resistivity (20°C) |

≤ 0.15713 Ω·g/m2 |

|

Thermal Conductivity |

≥ 398 W/m·K |

|

Tensile Strength (H80 temper) |

≥ 245 MPa |

|

Yield Strength |

≥ 205 MPa |

|

Elongation (over 5D) |

≥ 5% |

|

Hardness (Brinell HBW) |

Min 80 |

|

Grain Size (per ASTM E112) |

Uniform Fine Grain |

4. Applications of C10100 Copper Tubing

Our oxygen-free copper tubes are ideal for critical environments that demand ultra-high purity, stable electrical properties, and flawless surface integrity:

●Power Transmission & Substations – Copper bus tubes, conductors in 110–500 kV substations

● Vacuum Systems & Accelerators – UHV-compatible, hydrogen-free copper for particle physics

●Aerospace & Military Electronics – Wiring systems, waveguides, RF cavities

●Cryogenics & Medical Imaging – Liquid helium/nitrogen delivery, MRI machine components

● HVAC and Refrigeration – Seamless, high-purity tubes for precision cooling systems

●Semiconductor & Cleanroom Equipment – Oxygen-free piping for gas and cooling lines

● Solar Inverters & Battery Systems – High-conductivity busbars and interconnects

5. Quality Control & Laboratory Testing

To meet the highest quality standards, Womic Copper integrates comprehensive in-house inspection systems, including:

Advanced Equipment:

● Oxygen Analyzer (IR-based) – Detects oxygen to <3 ppm

● Atomic Absorption Spectrometer – Measures metallic trace impurities

● Eddy Current Testers – Non-destructive flaw detection

● Brinell & Vickers Hardness Testers – Ensures consistent mechanical properties

● Microstructure Analysis (SEM + Metallography) – Grain and inclusion assessment

● Universal Tensile Test Machines – Full mechanical strength verification

● Conductivity Test (IACS Measurement) – Verifies ≥101% performance

Third-Party Testing:

We fully support inspection by internationally certified bodies such as SGS, TÜV, BV, and DNV, with detailed reports issued prior to delivery.

6. Packaging, Shipping & Factory Service

Womic Copper provides safe, export-grade packaging to protect product quality during domestic or international shipment.

Packaging Features:

● Plastic end caps + individual poly wrap

●Vacuum-sealed PE bags to prevent oxidation

● Fumigated wooden crates with steel band reinforcement

● Each tube labeled with heat number, lot number, and specifications

Transportation:

●Available in FCL, LCL, and air freight

●Logistics service includes CIF, FOB, DDP, and EXW

●Reinforced loading + lashing for long-distance shipment

●Documents prepared for customs, port, and third-party agencies

7. Why Choose Womic Copper

●Ultra-Low Oxygen Control – 3–5 ppm oxygen level, industry leading

●Advanced Seamless Production – Full hot + cold drawing, annealing, H80 temper

●100% QC Tracing System – End-to-end digital traceability

●Worldwide Project Experience – Supplied 500kV substation systems in Asia and Europe

●Factory Audit Welcome – On-site inspection, transparent production

● Safe and Global Logistics – On-time delivery with complete documentation

Post time: Apr-05-2025