All casting steel and forged steel products can be OEM customized according to the drawings from customers. And we can arrange order production as per the drawings you provided.

Casting steel products: Slag pots, Rotary kiln wheel belt, crusher parts (Mantles &Concave, Bowl Liners ), mining machine parts, Electric Shovel spare parts (track shoe),

Forged steel products: Gear, Gear Shafts, Cylindrical Gears, OEM design gears, roller shafts, shafts and solutions.

Material Range: ASTM A27 GR70-40, ZGMn13Mo1, ZGMn13Mo2, ZG25CrNi2Mo, 40CrNi2Mo, SAE H-13, AISI 8620, ZG45Cr26Ni35, ZG40Cr28Ni48W5Si2, ZG35Cr20Ni80

ALLOY STEEL 4340 (36CrNiMo4), AISI 4140 Steel /42CrMoS4, UNS G43400, 18CrNiMo7-6, 17NiCrMo6-4, 18NiCrMo5, 20NiCrMo2-2, 18CrNiMo7-6, 14NiCrMo13-4, 20NiCrMo13-4, ZG35Cr28Ni16, ZGMn13Mo2

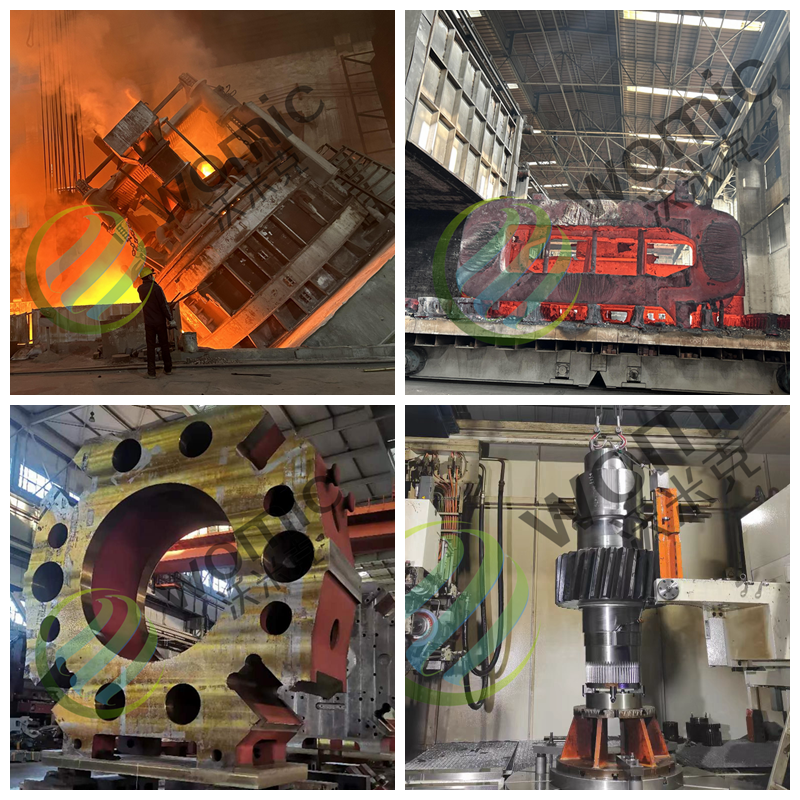

WOMIC STEEL also have a well-known foundry workshop for the casting steel products and forged steel products in northern China. Many casting steel products are supplied to all over the world, such as Mexico, South-America, Italy, Europe, the United States, Japan, Russia, South-east Asia and so on. With the abundant casting steel and forged steel process experience, WOMIC STEEL also improves the process technology continuously. The large-scale ball mill girth gear, different kinds of gears, gear shaft, supporting roller, copper mining used slag pots, machines, Electric Shovel spare parts (track shoe), crusher parts (Mantles &Concave, Bowl Liners ), and movable jaw produced by it have attracted many overseas customers to visit the company. And made them satisfied on our products.

After 20 years production and sales experience in the casting industry, we now have an experienced and skilled professional technical team, specializing in the production of large and extra-large steel castings. The production process adopts joint pouring, one-time organization of molten steel 450 tons, and the maximum single weight of castings can reach about 300 tons. The product industry involves mining, cement, ship, forging, metallurgy, bridge, water conservancy, One machining (group) center (5 TK6920 CNC boring and milling machines, 13 CNC 3.15M~8M double column vertical lathe (group), 1 CNC 120×3000 heavy duty plate rolling machine, 6 sets of φ1.25m-8m gear hobbing machine (group)) and so on.

Production equipment and testing equipment are complete. The maximum lifting capacity of a single vehicle is 300 tons, with one electric arc furnace of 30 tons and 80 tons, one double-station LF refining furnace of 120 tons, one rotary table shot blasting machine of 10m*10m, three high temperature heat treatment furnaces of 12m*7m*5m, 8m*4m*3.5m, 8m*4m*3.3m, and 8m* 4M *3.3m. Filter area 30,000 square meters electric arc furnace dust removal equipment. The independent testing center is equipped with chemical laboratory, direct reading spectrometer, impact testing machine, tensile testing machine, ultrasonic flaw detector, Leeb hardness tester, Metallographic phase microscope, etc.

Anytime on-site inspections are accepted by us, so that you will believe that the steel castings and forged products produced by WOMIC STEEL have the good quality and long service life, which can well meet the customers’ design requirements.

In order to solve the situation of high pollution and high energy consumption, WOMIC STEEL adopts intermediate frequency electric furnaces and installed dust collectors in the workshop. Now, the working environment of the workshop has been significantly improved. In the past, coke was burnt, but electricity is now used, which not only reduces energy consumption, saves energy and protects the environment, but also improves product accuracy.

WOMIC STEEL will further improve the factory’s hardware facilities, supporting automation equipment, application of automated procedures to pick up parts, cleaning and polishing, and automatic spraying, etc., to increase the degree of automation of the production process to more than 90%, and continue to improve technology.

The difference of casting steel products and forged steel products:

First, the production process is different

The production process of forgings and steel castings is different. Forged steel refers to all kinds of forged materials and forgings produced by forging method; Cast steel is the steel used to cast castings. Forging is the rolling of raw materials into the desired shape and size by impact and plastic deformation of metal materials. In contrast, steel castings are made by pouring molten metal into a pre-prepared model, which is solidified and cooled to obtain the desired shape and size. Forged steel is often used in the manufacture of some important machine parts; Cast steel is mainly used to manufacture some complex shapes, difficult to forge or cut forming and require high strength and plasticity parts.

Second, the material structure is different

The material structure of forgings and steel castings is also different. Forgings are generally more uniform and have better strength and fatigue resistance. Due to the relatively dense crystalline structure of forgings, they are not prone to deformation and thermal cracking when subjected to load. In contrast, the structure of cast steel is relatively loose, which is easy to produce plastic deformation and fatigue damage under the action of load.

Third, different performance characteristics

The performance characteristics of forgings and castings are also different. Forgings have high wear and corrosion resistance and are suitable for high strength and high frequency loads. In contrast, the wear resistance and corrosion resistance of cast steel parts are relatively poor, but they have good plasticity

Post time: Jun-26-2024