The Core Pillar of Precision Manufacturing:

WOMIC STEEL GROUP Cold Drawn Seamless Pipe Solutions Empowering Global Industrial Innovation

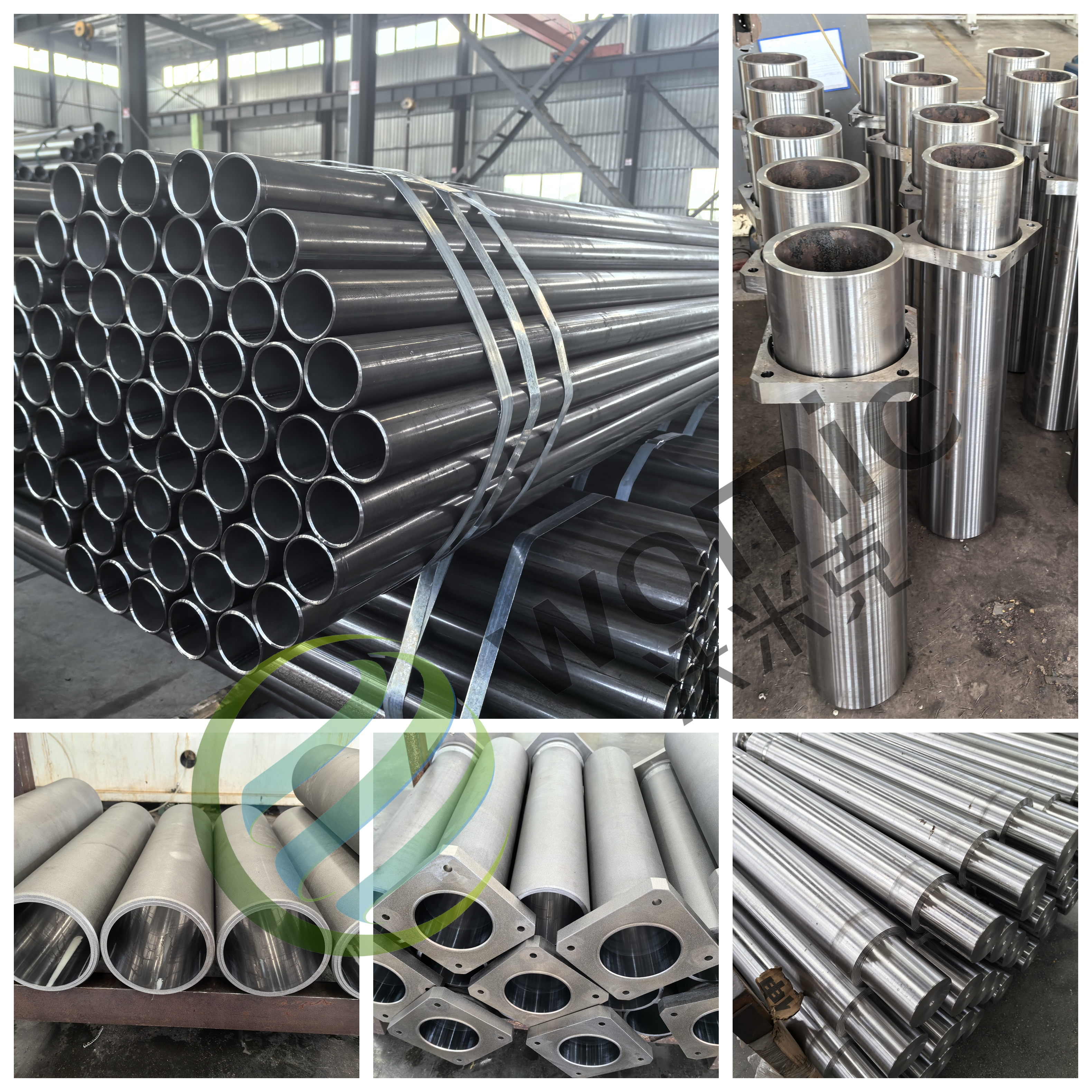

High-Quality Hydraulic Cylinder Precision Cold Drawn Seamless / Welded Steel Pipe / Steel Tube

In the pursuit of precision and reliability in industrial fields, cold drawn seamless pipes have become the “invisible backbone” of industries such as automotive, aerospace, and energy. With decades of technological expertise, WOMIC STEEL GROUP helps global customers break engineering limits with high-precision, high-strength, and corrosion-resistant cold drawn seamless pipe products.

Why Choose Cold Drawn Seamless Pipes?

Cold drawn seamless pipes use a unique cold working process to pull solid metal billets into seamless hollow structures, completely eliminating the weakness of welded seams. Their advantages far surpass those of traditional welded pipes:

Unmatched Strength: The grain structure is densified, enhancing tensile strength by more than 30%, capable of withstanding extreme pressure environments.

Millimeter-Level Precision: Inner and outer diameter tolerances are precise to ±0.1mm, meeting the needs for precision transmission and assembly.

All-Environment Corrosion Resistance: Utilizing high-purity alloy materials and surface treatment technologies, they adapt to corrosive environments like chemicals and marine conditions.

Lightweight Design: Weighing 15% less than welded pipes of the same specification, significantly reducing equipment energy consumption.

WOMIC’s Core Technology: Lean Manufacturing from Raw Material to Finished Product

We ensure the quality benchmark of every pipe with 7 key processes:

Selective Raw Materials: Using high-quality steel billets from Baosteel, Hengyang, TPCO, etc., with spectral testing to ensure material composition meets standards.

Intelligent Piercing: Precision-controlled temperature piercing technology eliminates internal stress concentration, establishing structural stability.

Multi-Stage Cold Drawing: Achieving optimal balance of wall thickness uniformity and surface smoothness through 12 progressive cold drawing stages.

Customized Heat Treatment: Tailored annealing/normalizing processes based on customer requirements, precisely controlling mechanical properties.

Zero Defect Detection: Automated flaw detection throughout the entire process (eddy current + ultrasonic), with a defect detection rate of 99.99%.

Eco-Friendly Surface Treatment: Offering 8 anti-corrosion options, including galvanizing and powder coating, complying with RoHS and REACH standards.

Intelligent Storage and Logistics: Constant temperature and humidity warehouses with custom shockproof packaging to ensure zero loss during global delivery.

Empowering Industries Across the Globe: WOMIC Cold Drawn Pipe Applications

New Energy Vehicles: Lightweight chassis and battery brackets, helping improve driving range by 12%.

Deep Sea Oil and Gas Extraction: Ultra-thick wall pipes (35mm) used successfully in the South China Sea 981 drilling platform’s high-pressure pipelines.

Aerospace: Titanium alloy cold drawn pipes used in the C919 landing gear hydraulic system, passing NASA-level fatigue testing.

Smart Equipment: Robotic joint bearing pipes, with precision up to IT5 grade, extending service life by 3 times.

WOMIC’s Four Commitments: Redefining Industry Service Standards

24-Hour Rapid Response:

Dedicated engineering team providing full support from product selection to after-sales service.

Most Cost-Effective Solutions: Scalable production and flexible customization, with prices 10%-15% lower than competitors.

Zero Delay Delivery: 100% on-time delivery rate with 6 global production bases in sync.

Full Lifecycle Management: Offering free pipe life prediction and maintenance solutions.

Customer Testimonials: The Choice of Global Top 500 Companies

“WOMIC’s φ21.3 – 406.6mm cold drawn pipes performed excellently in many different types of projects.

We specialize in the production of high-quality Hydraulic Cylinder Tubes that meet the demanding specifications of various industries such as construction, agriculture, and automotive.

Please find below our part of Production Range of High-Quality and Precision Steel Tubes/Pipes:

OD: 1/2 – 26 inch (21.3 – 660 mm)

OD & ID and Wall Thickness Tolerance controlled within ±0.1 mm

Ovality: 0.2 mm

The pipes produce by us regularly used for applications like Conveyor/Roller/Idler/Honed Cylinder/ Textile Mill/ Axles and Bushes

Common sizes include: 31.8 mm, 76.2 mm, 101.6 mm, 108 mm, 127 mm, 133.1 mm, 152.4 mm, 158.8 mm, 165.1 mm, 177.8 mm, 219.1 mm, and more

OEM customized sizes available, diameter, thickness, length, material can be requested by customers.

We would be delighted to discuss your requirements in more detail and explore how we can support your business with our precision hydraulic tubes.

Thank you for considering Womic Steel Group as your trusted partner for hydraulic solutions. We look forward to the opportunity to work with you.

If you are interested in receiving a product sample to test the quality first or would like a detailed quote, ple

Take Action Now for Efficient Collaboration!

Visit [www.womicsteel.com] for exclusive quotes. The first 100 inquiries can enjoy free samples and technical solution optimization services.

Contact Email: sales@womicsteel.com

WOMIC STEEL GROUP — Crafting Infinite Possibilities with Seamless Precision!

© 2025 WOMIC STEEL GROUP. All rights reserved. ISO 9001:2025 Certified Company | 23 Global Patents

Post time: Feb-21-2025