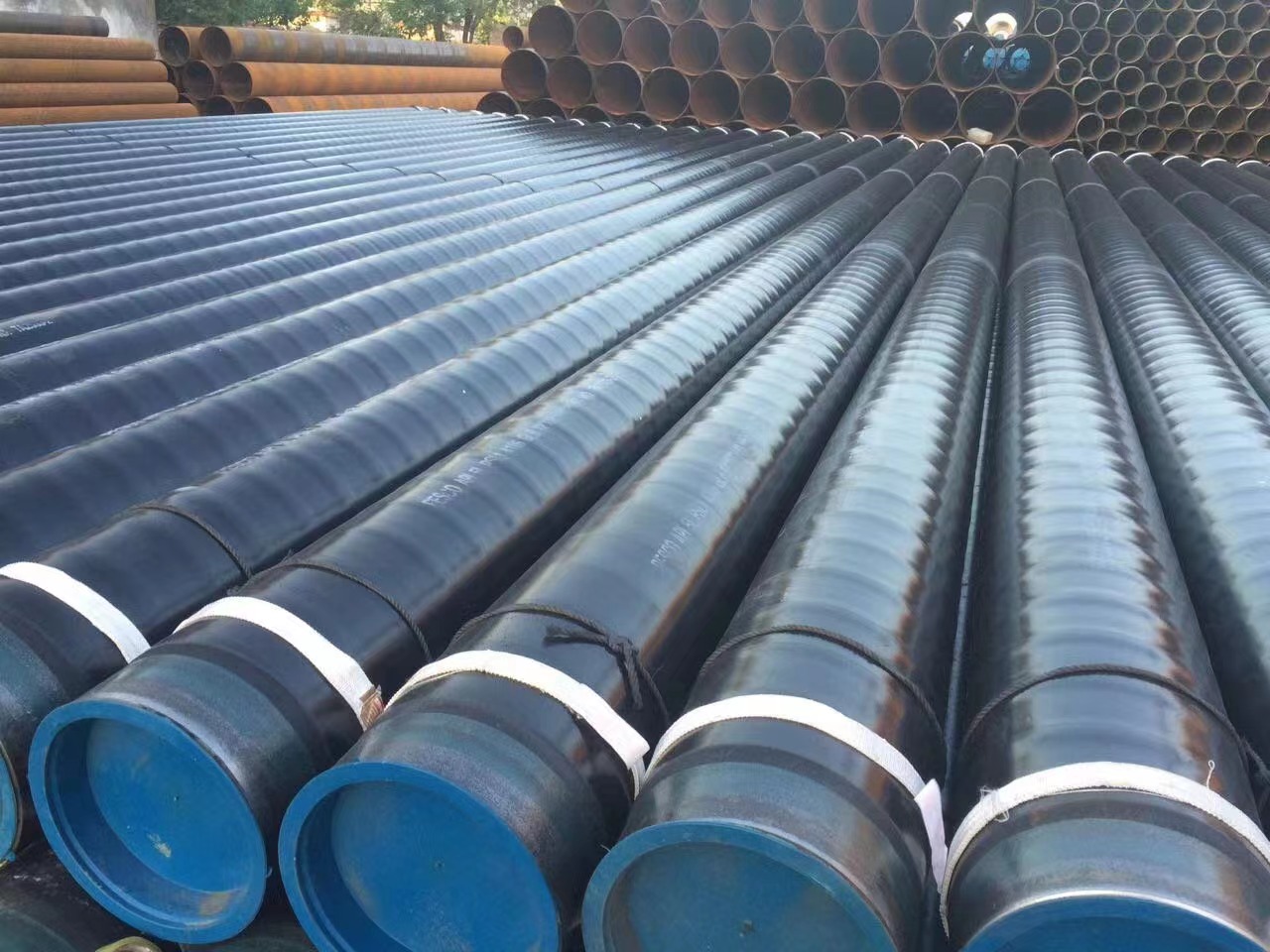

As global engineering advances, steel pipes stand as crucial mediums for transportation, playing an indispensable role in various projects. However, due to the diverse usage environments, steel pipes are prone to corrosion during transport and use, making anti-corrosion processes critically important. To address this issue, different countries and international standardization organizations have established various anti-corrosion standards such as AWWA C210/C213, DIN 30670, and ISO 21809. Guided by these standards, Womic Steel Group, as an exceptional manufacturer of steel pipes and anti-corrosion solutions, has successfully supplied pipeline products meeting these standards in oil and gas transportation projects, water treatment initiatives, and more in regions like South America, Southeast Asia, and Africa, showcasing outstanding capabilities in the field of pipeline corrosion protection.

The AWWA C210/C213 standard, established by the American Water Works Association, focuses on anti-corrosion treatment for steel pipes used in water conveyance, drainage, and sewage treatment. As an outstanding supplier adhering to this standard, Womic Steel has ensured the stability and reliable operation of pipeline systems in water treatment projects across South America by strictly following the anti-corrosion processes stipulated in the AWWA C210/C213 standard.

The DIN 30670 standard, devised by the German Institute for Standardization, applies to pipelines transporting petroleum, natural gas, kerosene, and water. In Southeast Asia's oil and gas transportation projects,Womic Steel has provided high-quality steel pipes compliant with the German industrial standards set in DIN 30670 by adhering rigorously to its anti-corrosion requirements.

The ISO 21809 standard, formulated by the International Organization for Standardization, is suitable for transportation pipeline systems in petrochemicals, natural gas, and kerosene industries. In Africa,Womic Steel has employed epoxy resin coating systems compliant with the ISO 21809 standard, delivering pipeline products with outstanding durability and corrosion resistance to its clientele.

Womic Steel’s successful practices demonstrate its remarkable capabilities and technical expertise in the field of anti-corrosion steel pipes. By strictly adhering to international standards and delivering high-quality anti-corrosion steel pipe products, Womic Steel not only meets the demands for superior pipeline products in oil and gas transportation and water treatment projects but also establishes a strong brand image in the international market.

Renowned for its exceptional product quality and service reputation, Womic Steel has been widely recognized in the global market. Moving forward, amidst the continuous development in the global engineering sector, We Womic Steel remains committed to upholding high anti-corrosion standards, continually enhancing product quality and technological advancements to offer more reliable anti-corrosion steel pipe products and solutions for engineering projects worldwide.

Post time: Dec-15-2023