Overview of ASTM A694 F65 Material

ASTM A694 F65 is a high-strength carbon steel widely used in the production of flanges, fittings, and other piping components designed for high-pressure transmission applications. This material is commonly utilized in the oil and gas, petrochemical, and power generation industries due to its excellent mechanical properties, including high strength and toughness.

Production Dimensions and Specifications

Womic Steel manufactures ASTM A694 F65 flanges and fittings in a broad range of dimensions to cater to various application needs. The typical production dimensions include:

• Outer Diameter: 1/2 inch to 96 inches

• Wall Thickness: Up to 50 mm

• Length: Customizable as per client requirements/Standard

Standard Chemical Composition

The chemical composition of ASTM A694 F65 is critical for its mechanical properties and performance. The typical composition includes:

• Carbon (C): ≤ 0.12%

• Manganese (Mn): 1.10% - 1.50%

• Phosphorus (P): ≤ 0.025%

• Sulfur (S): ≤ 0.025%

• Silicon (Si): 0.15% - 0.30%

• Nickel (Ni): ≤ 0.40%

• Chromium (Cr): ≤ 0.30%

• Molybdenum (Mo): ≤ 0.12%

• Copper (Cu): ≤ 0.40%

• Vanadium (V): ≤ 0.08%

• Columbium (Cb): ≤ 0.05%

Mechanical Properties

ASTM A694 F65 material exhibits outstanding mechanical properties, making it suitable for high-pressure applications. The typical mechanical properties include:

• Tensile Strength: 485 MPa (70,000 psi) minimum

• Yield Strength: 450 MPa (65,000 psi) minimum

• Elongation: 20% minimum in 2 inches

Impact Properties

ASTM A694 F65 requires impact testing to ensure its toughness at low temperatures. The typical impact properties are:

• Impact Energy: 27 Joules (20 ft-lbs) minimum at -46°C (-50°F)

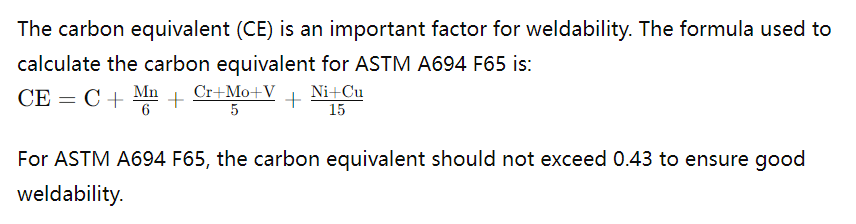

Carbon Equivalent

Hydrostatic Testing

ASTM A694 F65 flanges and fittings undergo rigorous hydrostatic testing to ensure their integrity and ability to withstand high pressure. The typical hydrostatic test requirements are:

• Test Pressure: 1.5 times the design pressure

• Duration: Minimum of 5 seconds without leakage

Inspection and Testing Requirements

Products manufactured under ASTM A694 F65 standard must undergo a series of inspections and tests to ensure compliance with specifications. The required inspections and tests include:

• Visual Inspection: To check for surface defects and dimensional accuracy.

• Ultrasonic Testing: To detect internal flaws and ensure material integrity.

• Radiographic Testing: For detecting internal imperfections and verifying weld quality.

• Magnetic Particle Testing: For identifying surface and slightly subsurface discontinuities.

• Tensile Testing: To measure the material’s strength and ductility.

• Impact Testing: To ensure toughness at specified temperatures.

• Hardness Testing: To verify the material’s hardness and ensure consistency.

Womic Steel's Unique Advantages and Expertise

Womic Steel is a renowned manufacturer of high-quality steel components, specializing in ASTM A694 F65 flanges and fittings. Our advantages include:

1.State-of-the-Art Production Facilities: Equipped with advanced machinery and technology, we ensure precise manufacturing of components with tight tolerances and superior surface finish.

2.Extensive Quality Control: Our rigorous quality control procedures ensure that every product meets or exceeds the required standards. We employ both destructive and non-destructive testing methods to verify material integrity and performance.

3.Experienced Technical Team: Our team of skilled engineers and technicians has extensive experience in the production and inspection of high-strength steel materials. They are capable of providing technical support and customized solutions to meet specific client requirements.

4.Comprehensive Testing Capabilities: We have in-house testing facilities for conducting all required mechanical, chemical, and hydrostatic tests. This allows us to ensure the highest quality and compliance with international standards.

5.Efficient Logistics and Delivery: Womic Steel has a well-established logistics network to ensure timely delivery of products to clients worldwide. We offer customized packaging solutions to protect the integrity of the products during transportation.

6.Commitment to Sustainability: We prioritize sustainable practices in our manufacturing processes, reducing waste and minimizing environmental impact.

Conclusion

ASTM A694 F65 is a high-performance material suitable for high-pressure applications in various industries. Womic Steel's expertise in manufacturing and quality control ensures that our flanges and fittings meet the stringent requirements of this standard, providing reliable and durable solutions for our clients. Our commitment to excellence and customer satisfaction makes us a trusted partner in the steel manufacturing industry.

Post time: Jul-28-2024