Womic Steel Group, a leading manufacturer of SANS 657-3 precise steel tubes (Steel tubes for rolls for conveyor belt idlers), excels in producing high-quality steel pipes that meet strict Conveyor roller industry production standards. Our production capabilities and advantages ensure that we deliver reliable and durable steel pipes for a wide range of applications.

Production Specifications

Our SANS 657-3 conveyor roller tube are manufactured according to the highest standards, ensuring superior quality and performance. Here are some key specifications:

|

Norminal Outside Diameter (mm) |

Actual Outside Diameter (mm) |

Outside Diameter(mm) |

Ovality Max |

Wall Thickness |

Weight of Tube |

|

|

Min |

Min |

(mm) |

Kgs/Mtr |

|||

|

101 |

101.6 |

101.8 |

101.4 |

0.4 | 3 |

9.62 |

|

127 |

127 |

127.2 |

126.8 |

0.4 | 4 |

12.13 |

|

152 |

152.4 |

152.6 |

152.2 |

0.4 | 4 |

18.17 |

|

165 |

165.1 |

165.3 |

164.8 |

0.5 | 4.5 |

19.74 |

|

178 |

177.8 |

178.1 |

177.5 |

0.5 | 4.5 |

25.42 |

|

219 |

219.1 |

219.4 |

218.8 |

0.6 | 6 | |

Note:If customer’s requirements are more strict,Outside Diameter&Ovality tolerance : Even±0.1mm can be satisfied.

Womic Steel's Production Advantages

Precision Manufacturing: Womic Steel utilizes advanced manufacturing techniques and equipment to ensure precise dimensions and tolerances, meeting the strict requirements of SANS 657-3.

High-Quality Materials: We source high-quality raw materials to ensure the durability and longevity of our steel pipes, meeting or exceeding the standard's specifications.

Third-Party Inspection: We accept third-party inspection to ensure the quality and reliability of our products, providing our customers with confidence and peace of mind.

Customization Options: We offer customization options for our SANS 657-3 conveyor roller tube, including different lengths, coatings, and end finishes, to meet the specific requirements of our customers.

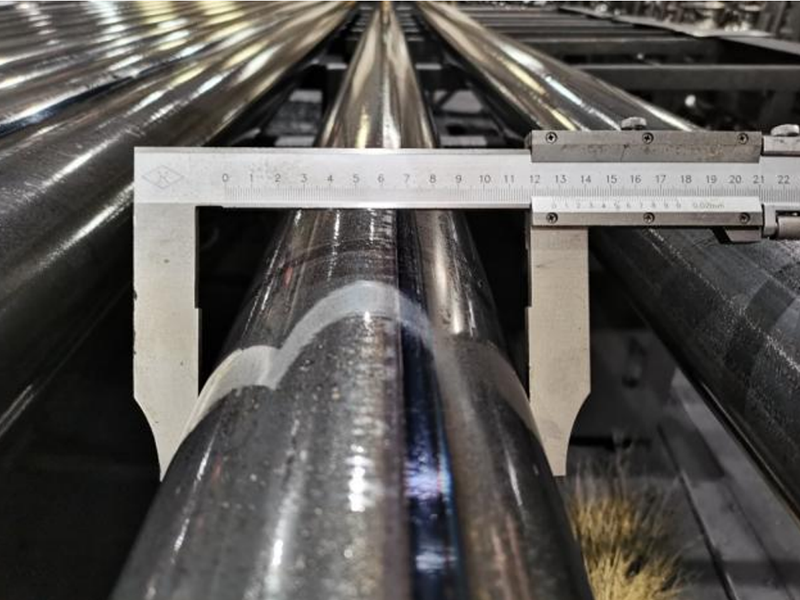

TOLERANCES CONTROL BY WOMIC

Tolerance control :

OD 101.6mm ~ 127mm, On Specified OD Tolerance ±0.1 mm, Ovality 0.2 mm;

OD 133.1mm ~ 219.1mm, On Specified OD Tolerance ±0.15mm, Ovality 0.3 mm;

On wall Thickness :

±0.2 mm for the pipe wall thickness below and include 4.5mm,

±0.28 mm for the pipe wall thickness above 4.5mm.

Straightness :

Shall not exceed 1 in 1000 (measured at the midpoint of the tube).

2)ENDS :Cut cleanly and nominally square with the axis of the tube and free from excessive burrs.

3)PROPERTIES

a) Chemical : % Max.C - 0.25%, S - 0.06%, P - 0.060%,

b) Mechanical:(Min.) UTS - 320 N/mm22 YS - 230 N/mm2 & %Elongation - 10%.

4) FLATTENING TEST

a) Weld Position 90°-Flatten until the distance between the two plates is 60% of the actual tube

b) Weld Position 0°-Flatten until the distance between the two plates is 15% of the actual tube OD.

5) FLARE TEST

Applying a steadily increasing force until the end of the test piece flares to a diameter 10% ± 1% Larger than the outside diameter of the pipe.

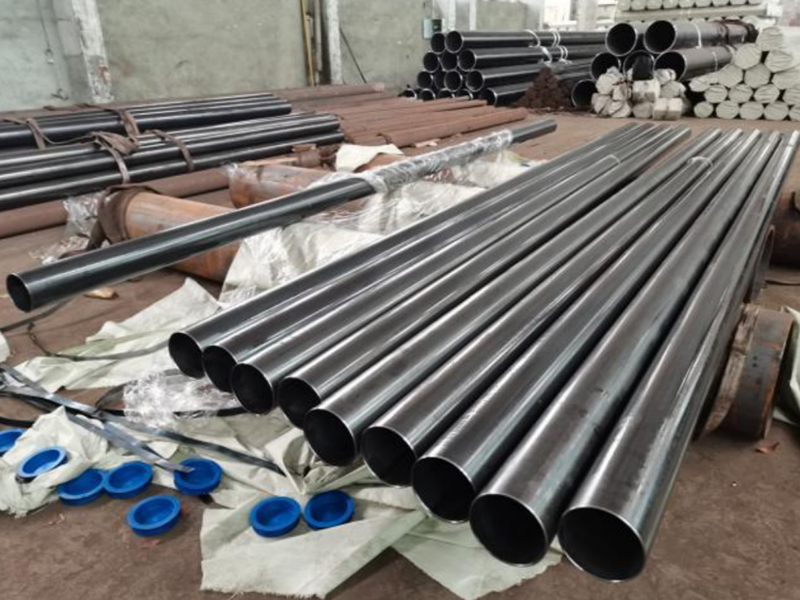

6) PACKING: Steel belt bundling, waterproof cloth packaging

7) MILL TEST CERTIFICATE: We can issue a MTC,Certifying that the tube supplied comply with this standard.

Womic Steel Group is a trusted manufacturer of SANS 657-3 conveyor roller tube, known for our commitment to quality, precision manufacturing, and customer satisfaction. With our extensive experience and advanced production capabilities, we are your ideal partner for high-quality steel pipes that meet the stringent requirements of the standard. Contact us today to learn more about our products and services.

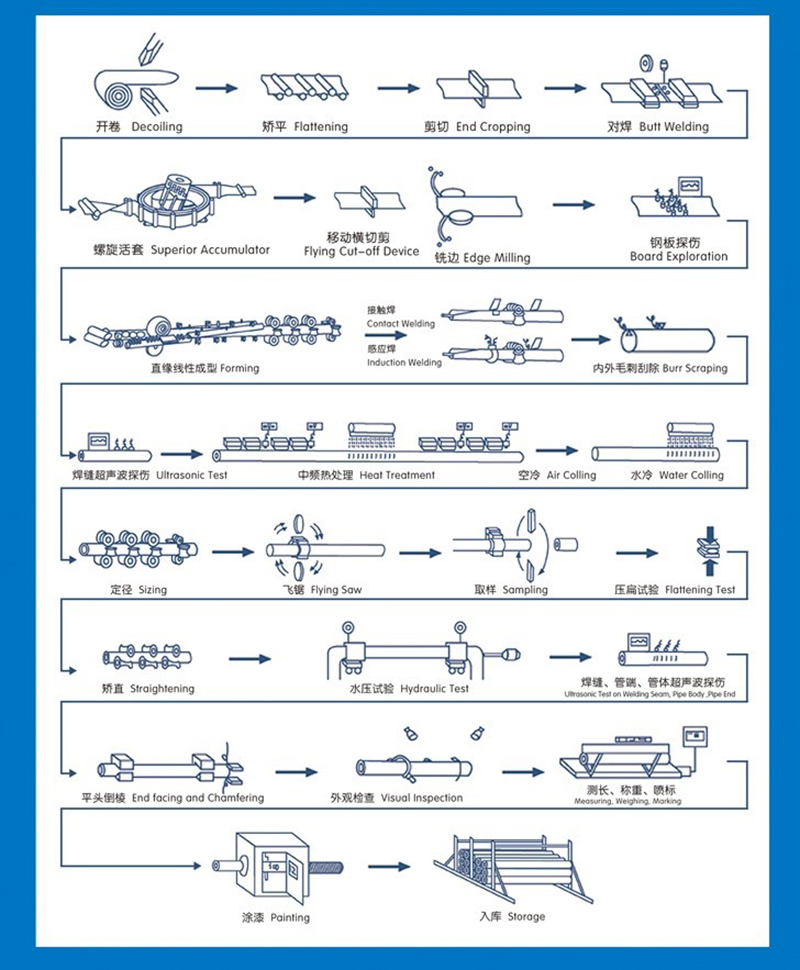

MPS OF THE ERW STEEL PIPES

Post time: May-09-2024