Womic Steel specializes in the production of high-quality steel pipes that comply with DIN 2391 standards. Our pipes are designed for a wide variety of applications, including structural, mechanical, and fluid transportation systems. Leveraging advanced manufacturing technology and stringent quality control processes, we ensure that our products meet international standards, providing unmatched durability, precision, and performance.

Our steel pipes are particularly well-suited for use in idlers, hydraulic and pneumatic cylinders, mechanical and automotive engineering, machinery, oil cylinder tubes, motorcycle shock absorber steel tubes, and auto shock absorber inner cylinders. These applications require high-strength, precision-engineered pipes that offer excellent reliability and performance in demanding environments.

DIN 2391 Seamless Precision Tubes Production Range:

- Outside Diameter (OD): 6 mm to 400 mm

- Wall Thickness (WT): 1 mm to 18 mm

- Length: Custom lengths available, typically ranging from 6 meters to 12 meters, depending on the project requirements.

DIN 2391 Seamless Precision Tubes Tolerances:

|

Parameter |

Tolerance |

| Outside Diameter (OD) | ± 0.01mm |

| Wall Thickness (WT) | ± 0.1 mm of the specified wall thickness |

| Ovality (Ovalness) | 0.1 mm |

| Length | ± 5 mm |

| Straightness | Max 1 mm per meter |

| Surface Finish | As per customer specification (Commonly:Anti-rust Oil,Hard chrome plating,Nickel chromium plating, or other Coating) |

| Squareness of Ends | ± 1° |

DIN 2391 Seamless Precision Tubes Chemical Composition

|

Standard |

Grade |

Chemical Components (%) |

|||||

|

Symbol |

Material No. |

C |

Si |

Mn |

P |

S |

|

|

DIN2391 |

St 30 Si |

1.0211 |

≤0.10 |

≤0.30 |

≤0.55 |

≤0.025 |

≤0.025 |

|

St 30 Al |

1.0212 |

≤0.10 |

≤0.05 |

≤0.55 |

≤0.025 |

≤0.025 |

|

|

St 35 |

1.0308 |

≤0.17 |

≤0.35 |

≥0.40 |

≤0.025 |

≤0.025 |

|

|

St 5 |

1.0408 |

≤0.21 |

≤0.35 |

≥0.40 |

≤0.025 |

≤0.025 |

|

|

St 52 |

1.058 |

≤0.22 |

≤0.55 |

≤1.60 |

≤0.025 |

≤0.025 |

|

The following alloying elements may be added: Nb: ≤ 0,03 %; Ti: ≤ 0,03 %; V: ≤ 0,05 %; Nb + Ti + V: ≤ 0,05 %

DIN 2391 Seamless Precision Tubes Delivery Conditions

The tubes shall be manufactured from cold drawn or cold rolled processes. The tubes shall be supplied in one of the delivery conditions as follows:

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and thus, have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

DIN 2391 Seamless Precision Tubes Mechanical Properties.

|

Mechanical properties at room temperature |

|||||||||||||

|

Steel Grade |

Minimum values for the delivery condition |

||||||||||||

|

Steel Name |

Steel Number |

BK |

BKW |

BKS |

GBK |

NBK |

|||||||

|

Rm |

A % |

Rm |

A % |

Rm |

ReH |

A % |

Rm |

A % |

Rm |

ReH |

A % |

||

|

Mpa |

Mpa |

Mpa |

Mpa |

Mpa |

Mpa |

Mpa |

|||||||

|

St 30 Si |

1.0211 |

430 |

8 |

380 |

12 |

380 |

280 |

16 |

280 |

30 |

290 to 420 |

215 |

30 |

|

St 30 Al |

1.0212 |

430 |

8 |

380 |

12 |

380 |

280 |

16 |

280 |

30 |

290 to 420 |

215 |

30 |

|

St 35 |

1.0308 |

480 |

6 |

420 |

10 |

420 |

315 |

14 |

315 |

25 |

340 to 470 |

235 |

25 |

|

St 45 |

1.0408 |

580 |

5 |

520 |

8 |

520 |

375 |

12 |

390 |

21 |

440 to 570 |

255 |

21 |

|

St 52 |

1.0580 |

640 |

4 |

580 |

7 |

580 |

420 |

10 |

490 |

22 |

490 to 630 |

355 |

22 |

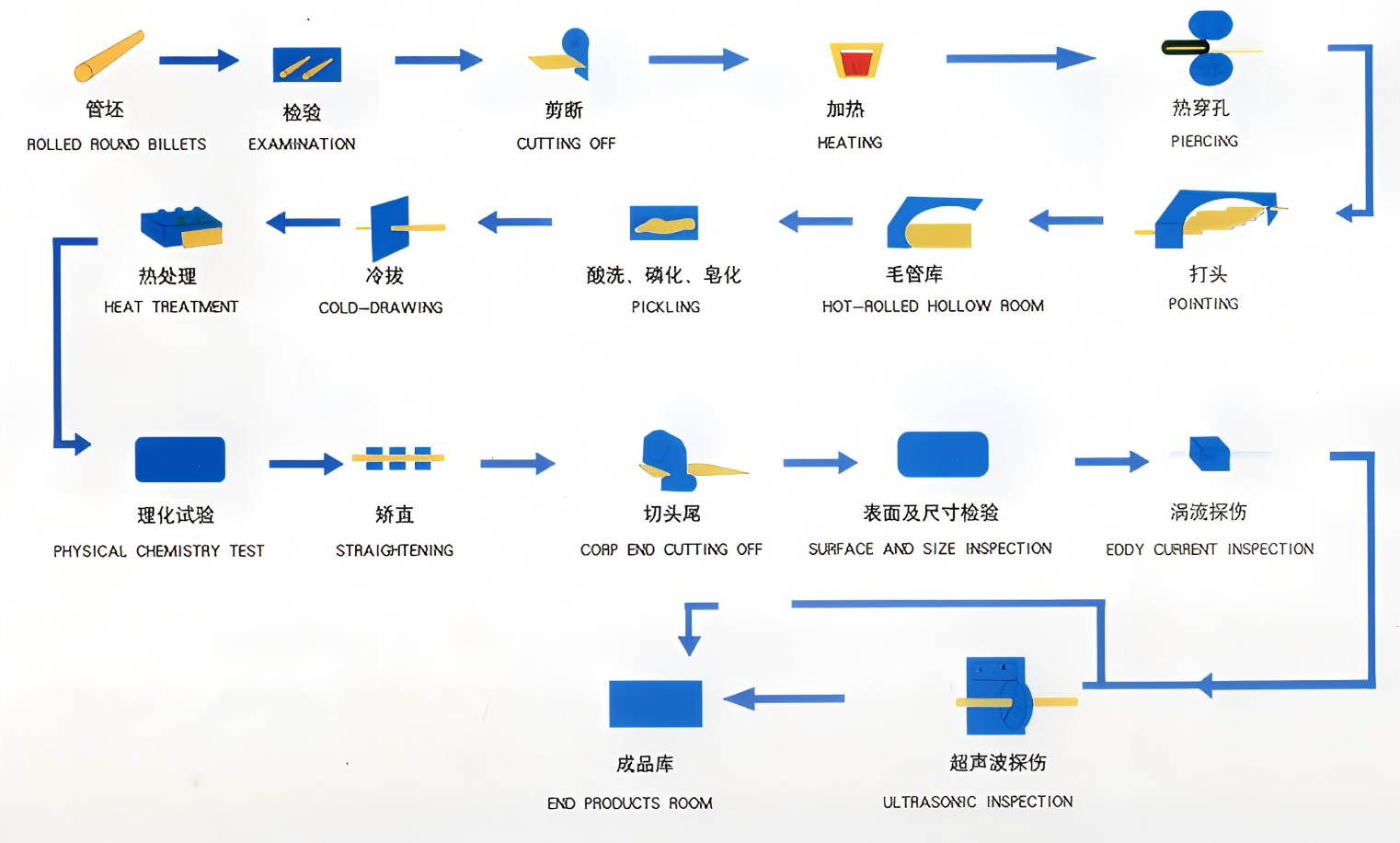

DIN 2391 Seamless Precision Tubes Manufacturing Process:

●Rolled Round Billets: The production begins with the use of rolled round billets, which are the initial raw material in the form of steel rods.

●Examination: These billets are first examined for quality and consistency to ensure they meet the necessary standards before proceeding to the next step.

●Cutting Off: The billets are then cut to the desired length to fit the requirements for further processing.

●Heating: The cut billets are heated to a high temperature to make them suitable for further deformation in the following steps.

●Piercing: The heated billets are then pierced to create a hollow center, which forms the basic structure of the seamless pipe.

●Hot-Rolled Hollow Room: The hollow billets undergo hot-rolling to further shape the pipe.

●Cold-Drawn: The hot-rolled pipes are then drawn through a die under controlled conditions, reducing the diameter and thickness, and refining the pipe's dimensions.

●Pickling: The pipes are pickled in an acid solution to remove any surface scale or impurities formed during the manufacturing process.

●Heat Treatment: The pipes are subjected to heat treatment, which involves processes like annealing to improve their mechanical properties and relieve stresses.

●Physical Chemistry Test: The pipes undergo physical and chemical tests to ensure that they meet the required material specifications and properties.

●Straightening: After heat treatment, the pipes are straightened to ensure their uniformity and precision.

●Coil End Cutting Off: The ends of the pipes are trimmed to the required length.

●Surface and Size Inspection: The pipes are thoroughly inspected for surface defects and checked for dimensional accuracy to ensure quality.

●Eddy Current Inspection: This non-destructive test is used to detect any surface cracks or defects that might not be visible to the naked eye.

●Ultrasonic Inspection: The pipes undergo ultrasonic testing to detect any internal defects or flaws that could affect the pipe's strength or integrity.

●End Products Room: Finally, the finished pipes are sent to the end products room, where they are packaged and prepared for shipment.

Testing & Inspection:

Womic Steel guarantees full traceability and quality assurance for allDIN 2391 Seamless Precision Tubes through the following tests:

- Dimensional Inspection: Measurement of OD, WT, length, ovality, and straightness.

- Mechanical Testing:

- Tensile Test

- Impact Test

- Hardness Test

- Non-Destructive Testing (NDT):

- Eddy Current Test for internal defects

- Ultrasonic Testing (UT) for wall thickness and integrity

- Chemical Analysis: Conducted to verify the material composition using spectrographic methods.

- Hydrostatic Test: To check the pipe's ability to withstand internal pressure without failure.

Laboratory & Quality Control:

Womic Steel operates a fully equipped laboratory with advanced testing and inspection equipment to ensure compliance with DIN 2391 Seamless Precision Tubes standards. Our technical experts conduct regular in-house quality checks on every batch of pipes. We also work closely with independent third-party agencies for external verification of pipe quality.

Packaging

Protective Coating: Each tube is cleaned and coated with an anti-corrosion layer to prevent oxidation or rusting during transport and storage. This may include a layer of oil, wax, or other protective coatings as per customer requirements.

End Caps: Both ends of the tubes are sealed with plastic or metal end caps to prevent dirt, moisture, and damage during handling and transportation.

Bundling: The tubes are bundled into manageable packages, typically in lengths that align with standard shipping requirements. Bundles are wrapped with steel straps, plastic bands, or woven straps to hold them together securely.

Protection between Tubes: To avoid direct contact and prevent scratching or damage, tubes within the bundles are often separated by protective materials such as cardboard, wooden spacers, or foam inserts.

Packaging Material: The bundles of tubes are often wrapped in shrink wrap or heavy-duty plastic film to ensure they remain intact during transportation and are protected from dust and moisture.

Identification and Labeling: Each package is clearly marked with the product details, including the grade of steel, dimensions (diameter, thickness, length), quantity, batch number, and other relevant specifications. Labels may include handling instructions such as "Keep Dry" or "Handle with Care."

Transportation

Mode of Transport:

Sea Freight: For international shipments, seamless precision tubes are commonly shipped by sea. The bundles are loaded into shipping containers or onto flat racks, depending on the size and length of the tubes.

Rail or Road Transport: For domestic or regional shipments, the tubes can be transported by rail or road, loaded onto flatbed trucks or in containers.

Loading and Securing: When loaded onto transport vehicles, the bundles are securely fastened to prevent shifting or movement during transit. This can be achieved using steel straps, plastic bands, and additional bracing within the container or truck. For sea freight, if the tubes are not in containers, they are often loaded onto flat racks and secured with additional tarps or covers to shield them from weather conditions like rain or saltwater exposure.

Climate Control: If required (especially in humid or coastal regions), controlled transportation conditions (e.g., temperature and humidity control) can be arranged to prevent any damage from environmental factors during transit.

Documentation: Proper shipping documents are prepared for customs clearance and transportation tracking, including the bill of lading, certificate of origin, quality certificates, and other necessary regulatory documents.

Insurance: To protect against potential damage, loss, or theft during transit, it is recommended to arrange insurance coverage for the shipment, especially for international shipments.

Advantages of Choosing Womic Steel:

- Precision Manufacturing: Our state-of-the-art production processes allow us to meet the strictest tolerances for diameter, wall thickness, and ovality.

- High-Quality Materials: We source only the highest-grade steel from trusted suppliers, ensuring excellent mechanical properties and corrosion resistance.

- Customization: We offer tailored solutions based on customer needs, including specific lengths, surface treatments, and packaging options.

- Comprehensive Testing: With our rigorous testing procedures, we ensure each pipe meets all technical and regulatory requirements, delivering reliable and durable performance.

- Experienced Team: Our team of engineers and technicians are highly skilled and knowledgeable, ensuring the highest standards in production and customer service.

- On-Time Delivery: We work with a reliable logistics network, ensuring timely deliveries to any part of the world.

Conclusion:

Womic Steel’s DIN 2391 Seamless Precision Tubes are synonymous with high performance, durability, and precise manufacturing. Our commitment to quality and customer satisfaction sets us apart as a leader in steel pipe production. Whether for construction, machinery, or fluid systems, our products are designed to meet the highest standards of reliability and strength.

Choose Womic Steel Group as your reliable partner for high-quality Stainless Steel Pipes&Fittings and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Feb-02-2025