Product Overview

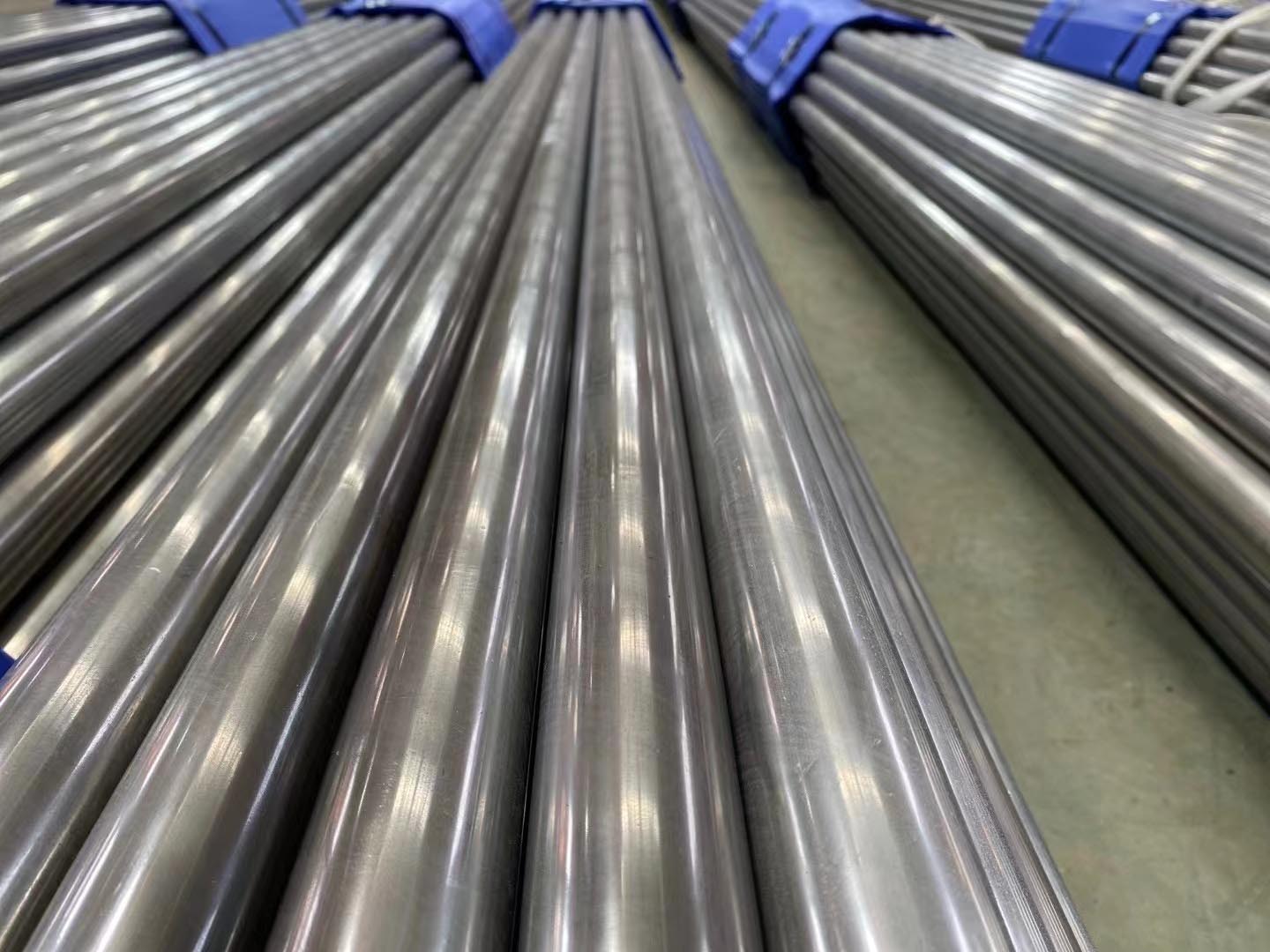

Womic Steel specializes in the production of high-quality DIN 2445-certified seamless steel tubes, engineered for precision and durability. Our tubes are suitable for various demanding applications, including fluid transportation systems, hydraulic components, automotive systems, and mechanical engineering. With advanced manufacturing technology and strict quality control processes, we ensure that our products meet international standards, delivering exceptional reliability and performance in every use case.

Our DIN 2445 seamless steel tubes are ideal for applications requiring high-strength, precision-engineered pipes that deliver superior performance in both static and dynamic environments. These pipes are widely used in fluid transport systems, hydraulic cylinders, machinery, automotive systems, and industrial equipment.

DIN 2445 Seamless Steel Tubes Production Range

●Outside Diameter (OD): 6 mm to 400 mm

●Wall Thickness (WT): 1 mm to 20 mm

●Length: Custom lengths available, typically ranging from 6 meters to 12 meters, depending on the project requirements.

DIN 2445 Seamless Steel Tubes Tolerances

Womic Steel guarantees precise dimensional accuracy, with the following tolerances applied to our DIN 2445 seamless steel tubes:

|

Designation |

Symbol |

Description |

| Cold Finished (Hard) | BK | Tubes that do not undergo heat treatment following final cold forming. High resistance to deformation. |

| Cold Finished (Soft) | BKW | Cold drawing is followed by heat treatment with limited deformation for flexibility in further processing. |

| Cold Finished and Stress-Relieved | BKS | Heat treatment applied to relieve stress following the last cold forming, enabling further processing and machining. |

| Annealed | GBK | Final cold forming process is followed by annealing in a controlled atmosphere to improve ductility and ease further processing. |

| Normalized | NBK | Cold forming followed by annealing above the upper transformation point to refine mechanical properties. |

DIN 2445 Seamless Steel Tubes Mechanical Properties

The mechanical properties for DIN 2445 steel tubes, measured at room temperature, vary based on the steel grade and delivery condition:

|

Steel Grade |

Minimum values for the delivery condition |

|

St 37.4 |

Rm: 360-510 MPa, A%: 26-30 |

|

St 44.4 |

Rm: 430-580 MPa, A%: 24-30 |

|

St 52.4 |

Rm: 500-650 MPa, A%: 22-30 |

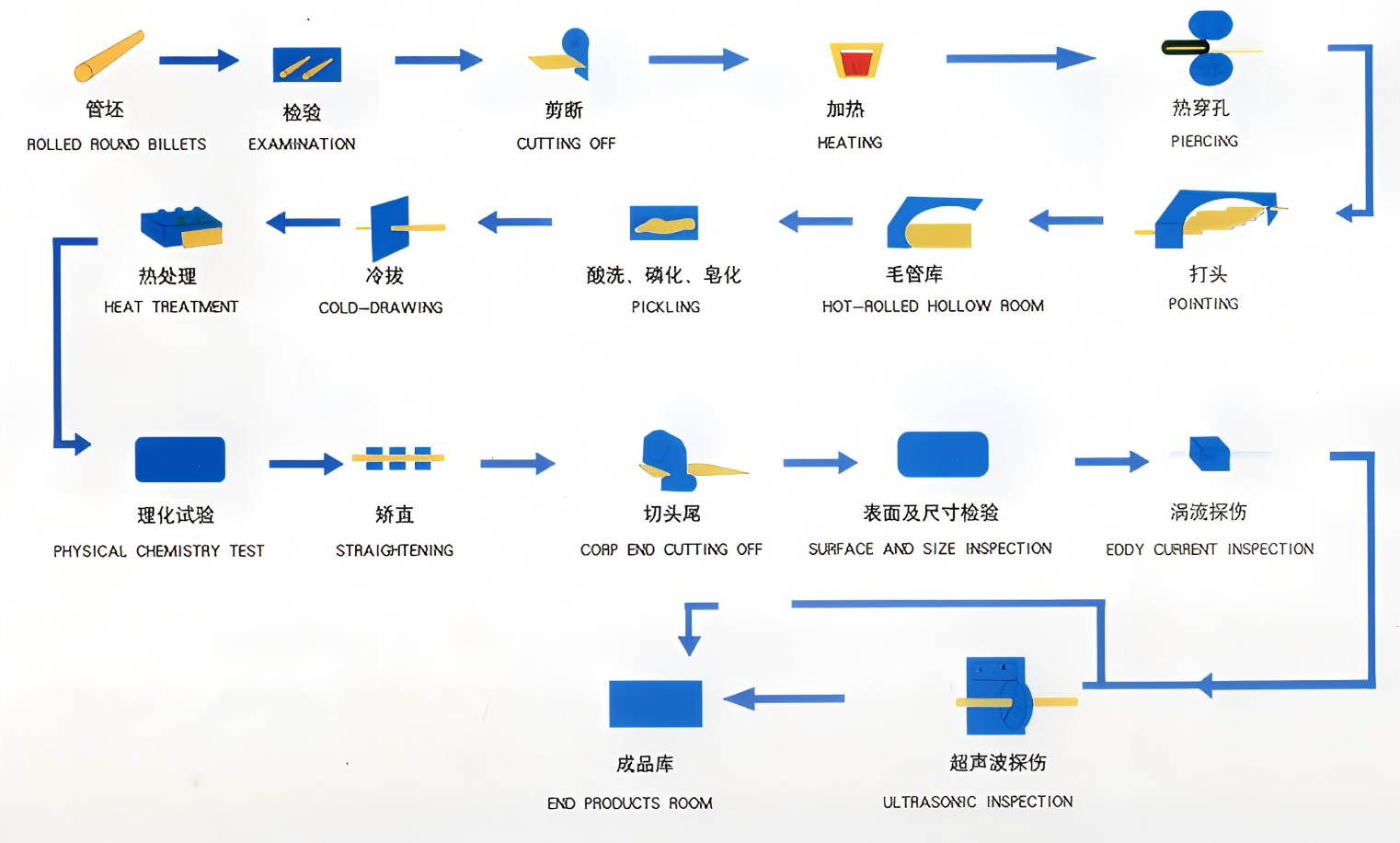

DIN 2445 Seamless Steel Tubes Manufacturing Process

Womic Steel employs advanced manufacturing technology to produce DIN 2445 seamless steel tubes, ensuring high precision and durability. Our manufacturing process includes:

●Billet Selection & Inspection: The production begins with high-quality steel billets, inspected for consistency and quality before processing.

●Heating & Piercing: The billets are heated and pierced to form a hollow tube, setting the foundation for further shaping.

●Hot-Rolling: The pierced billets are hot-rolled to achieve the desired dimensions.

●Cold Drawing: The hot-rolled pipes are cold drawn to achieve precise diameters and wall thicknesses.

●Pickling: The pipes are pickled to remove impurities, ensuring a clean surface.

●Heat Treatment: Tubes undergo heat treatment processes such as annealing to optimize mechanical properties.

●Straightening & Cutting: The tubes are straightened and cut to custom lengths as per customer specifications.

●Inspection & Testing: Comprehensive inspections, including dimensional checks, mechanical testing, and non-destructive tests like eddy current and ultrasonic testing, are carried out to ensure product quality.

Testing & Inspection

Womic Steel guarantees full traceability and quality assurance for all DIN 2445 seamless steel tubes through the following tests:

●Dimensional Inspection: Measurement of OD, WT, length, ovality, and straightness.

●Mechanical Testing: Tensile test, impact test, and hardness test.

●Non-Destructive Testing (NDT): Eddy current testing for internal defects, ultrasonic testing (UT) for wall thickness and integrity.

●Chemical Analysis: Material composition verified through spectrographic methods.

●Hydrostatic Test: Tests the pipe's ability to withstand internal pressure without failure.

Laboratory & Quality Control

Womic Steel operates a fully equipped laboratory with advanced testing and inspection equipment. Our technical experts perform in-house quality checks on every batch of tubes, ensuring compliance with DIN 2445 standards. Third-party agencies also conduct external verification for additional quality assurance.

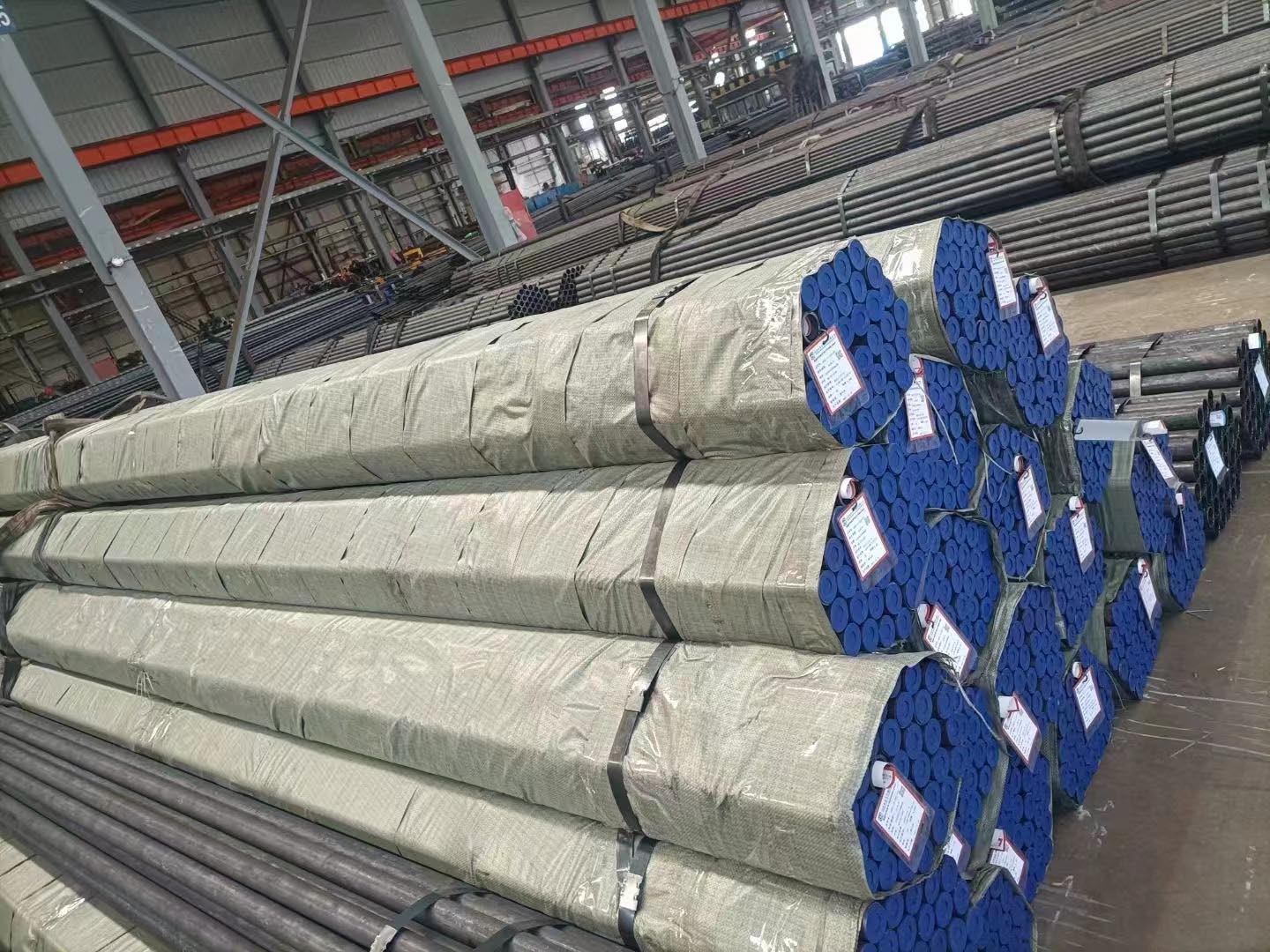

Packaging

To ensure the safe transport of our DIN 2445 seamless steel tubes, Womic Steel follows the highest packaging standards:

●Protective Coating: Anti-corrosion coating to prevent rust and oxidation.

●End Caps: Sealing both ends of the tubes with plastic or metal caps to prevent contamination.

●Bundling: Tubes are bundled securely with steel straps, plastic bands, or woven straps.

●Shrink Wrapping: Bundles are wrapped in shrink film to protect them from environmental factors.

●Labeling: Each bundle is clearly labeled with essential product details, including steel grade, dimensions, and quantity.

Transportation

Womic Steel ensures timely and secure global delivery of DIN 2445 seamless steel tubes:

●Sea Freight: For international shipments, tubes are loaded into containers or flat racks and shipped globally.

●Rail or Road Transport: Domestic and regional deliveries are made by rail or truck, with proper securing methods to prevent shifting.

●Climate Control: We can provide climate-controlled transportation when required, especially for sensitive materials.

●Documentation & Insurance: Comprehensive shipping documents and insurance are provided to ensure the safe and reliable delivery of goods.

Advantages of Choosing Womic Steel

●Precision Manufacturing: High accuracy in dimensional tolerances and mechanical properties.

●Customization: Flexible solutions for length, surface treatment, and packaging.

●Comprehensive Testing: Rigorous testing ensures every product meets industry standards.

●Global Delivery: Reliable and timely delivery worldwide.

●Experienced Team: Highly skilled engineers ensuring the highest standards of production and customer service.

Conclusion

Womic Steel's DIN 2445 Seamless Steel Tubes deliver superior strength, reliability, and precision for various demanding applications. Our commitment to quality, stringent testing, and flexible customer solutions make us a trusted partner for seamless tube production.

Choose Womic Steel for DIN 2445 Seamless Steel Tubes and experience top-notch quality and customer service.

For more details, please contact us directly:

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Feb-11-2025