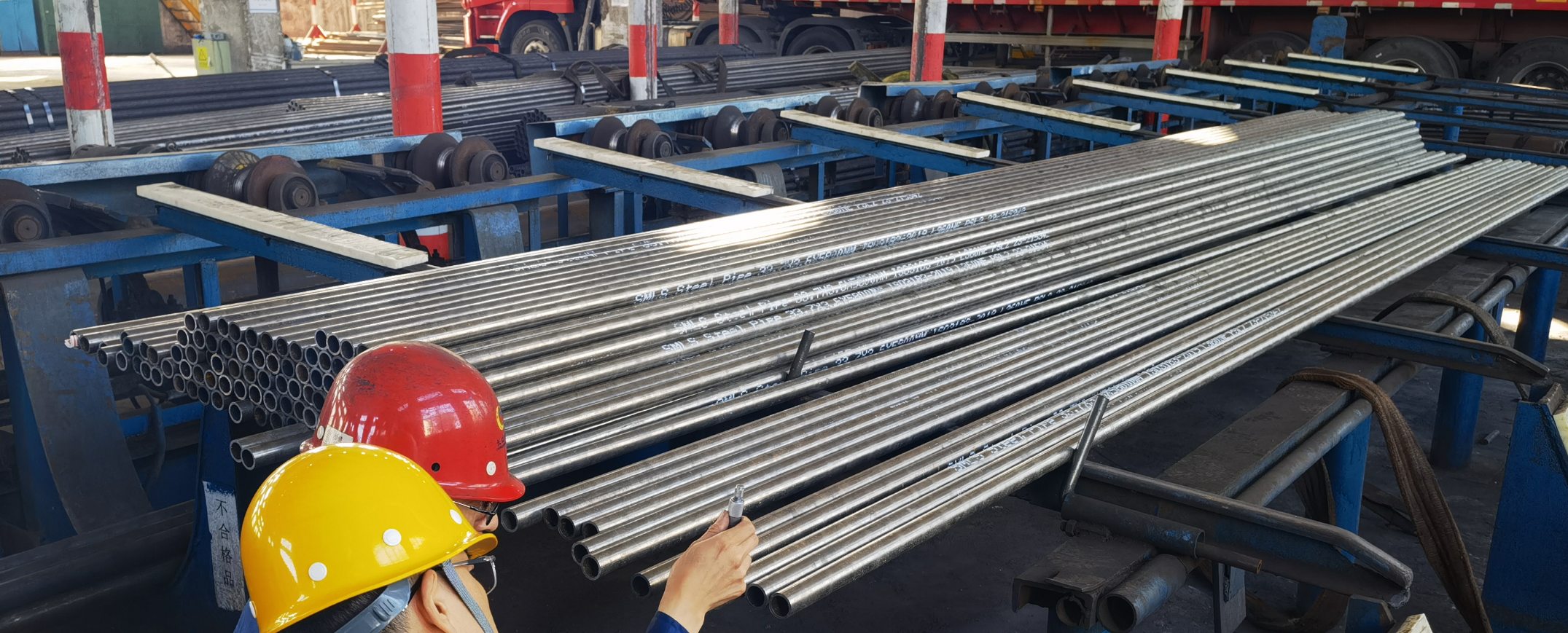

1.0345 carbon steel tube supplier in China

EN10216-2 TC2 P235GH 1.0345 Seamless Alloy Steel Tubes for Caldera, Boiler

Womic Steel Group, which is one of the leading steel pipes and fittings manufacturer in China, Womic supply alloy seamless steel boiler tubes with high quality and competitive price to our clients and well experienced in exporting and shipping. The P235GH EN 10216-2 TC2 Tubes which manufacture from carbon steel as well as low alloy steel grades tend to be resistant to loads under very high pressure and high temperatures usages.

Charastertistic: Resistance, Pressure Resistance, Good Weldability, Corrosion Resisitance, Versatility

The EN 10216-2 standard specifies the requirements for seamless non-alloy and alloy steel tubes for specified elevated temperature conditions. Primarily used in the construction of pressure equipment such as boilers, heat exchangers, and pipelines.

EN 10216-2 P235gh pipes produced by Womic Steel are widely used with elevated temperature applications such as oil and gas, heat exchangers and pressure vessels. The EN 10216-2 P235gh Tc2 is a carbon alloy steel material that is normalized. The composition of the material makes it possible to have higher mechanical properties. The EN 10216-2 Pipe Dimensions range from 10.2mm to 711mm in outer diameters. The wall thicknesses of the pipes range from 1.6mm to 100mm. the schedules range from sch5 through XXS. The heavier wall thicknesses are also available according to customer requirements. The P235gh Steel Pipe produced by Womic Steel has carbon, silicon, manganese, phosphorus, sulfur, molybdenum, nickel, chromium and copper in the composition. The P235gh Steel Material in Womic STEEL has 360MPa minimum yield strength and 500MPa minimum tensile strength. The EN 10216-2 material has many different grades with yield strengths ranging from 300MPa to 630MPa and minimum tensile strengths ranging from 40MPa to 830MPa. The EN 10216-2 Grade P235gh Alloy Steel Seamless Tubes produced by Womic Steel can be of different types such as capillary tubes, heat exchanger tubes, cold drawn tubes, hot rolled tubes and so on. The production of the products can be through seamless or welded means. There are EN 10216-2 P265gh Equivalent grades which can be used in place of the material. Depending on the requirement and cost efficiency, the equivalent materials can also be used. The EN 10216-2 P235gh Tc1 is used in oil and gas, boiler, heat exchangers, power generation and in other high temperature high pressure applications.

Chemical Composition % Max

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

Al a |

Cu b |

Nb c |

Ti c |

V c |

Cr+Cu+Mo+Ni |

|

0.16 |

0.35 |

1.2 |

0.025 |

0.02 |

0.3 |

0.08 |

0.3 |

0.02 |

0.3 |

0.01 |

0.04 |

0.02 |

0.7 |

a This requirement is not applicable provided the steel contains a sufficient amount of other nitrogen binding elements which shall be reported.When using titanium, the producer shall verify that(Al+Ti/2)≥0,020%.

b Option 2: In order to fecilitae subsequent forming operations, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply.

c The content of these elements need not to be reported unless intentionally added to the cast.

Mechanical Property

|

Steel grades |

Upper yield limit or yield strength ReH or Rp0,2 for wall thickness of t min |

Tensile strength Rm |

Elongation A min% |

||||

|

T≤16 |

16<T≤ 40<t<=40< span=""> |

40<T≤ 60<t<=60< span=""> |

60<T≤ 100<t<=60< span=""> |

||||

|

MPa |

MPa |

MPa |

MPa |

MPa |

I |

t |

|

|

P235GH |

235 |

225 |

215 |

- |

360- 500 |

25 |

23 |

Applications

Pipeline ---- EN 10216-P235GH (1.0345) TC2

Oil Industries ---- EN 10216-P235GH (1.0345) TC2

Gas Distribution ---- EN 10216-P235GH (1.0345) TC2

Power Industries ---- EN 10216-P235GH (1.0345) TC2

Nuclear Power Generation ---- EN 10216-P235GH (1.0345) TC2

Heat Exchangers/Boilers/Condensers,etc ---- EN 10216-P235GH (1.0345) TC2

Welcome to contact us for more details !

sales@womicsteel.com

Post time: Oct-30-2024