1.Product Overview

Womic Steel specializes in the production of high-quality copper tubes conforming to the EN 1057 standard. These tubes are made from Cu-DHP (CW024A) material, ensuring exceptional purity and performance for plumbing, gas distribution, heating, and cooling applications. With a minimum copper and silver content of 99.9% and a controlled phosphorus range between 0.015% and 0.040%, our copper tubes exhibit excellent corrosion resistance, durability, and ease of installation.

EN 1057 copper tubes are designed for use in both domestic and industrial environments, providing reliable performance in potable water systems, central heating, refrigeration, and medical gas pipelines . Manufactured to stringent quality standards, these tubes offer superior mechanical properties and long-term service reliability.

2.EN 1057 Copper Tubes Production Range

●Outside Diameter (OD): 6 mm to 267 mm

●Wall Thickness (WT): 0.3 mm to 20 mm

●Length: Standard lengths of 3m, 5m, or 6m; custom lengths available upon request

●Coiled Tubes: Available in 25m or 50m coils for flexible installation

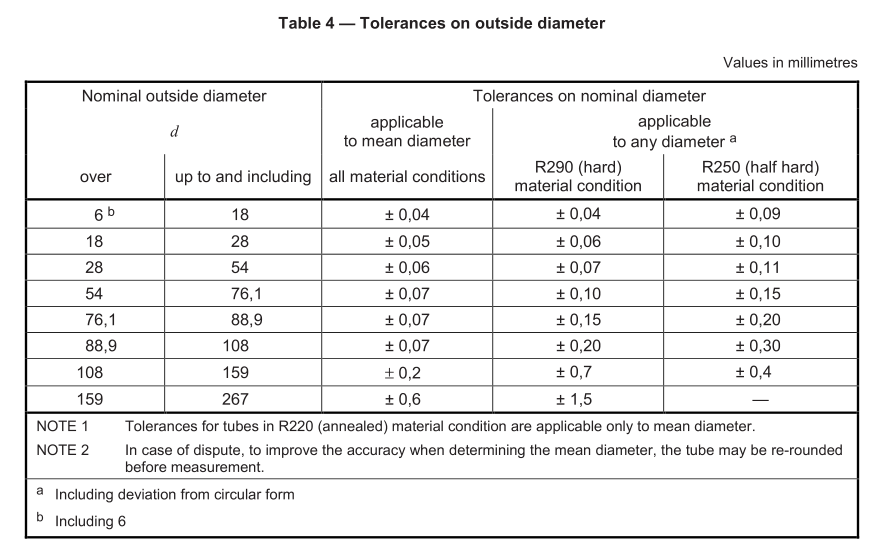

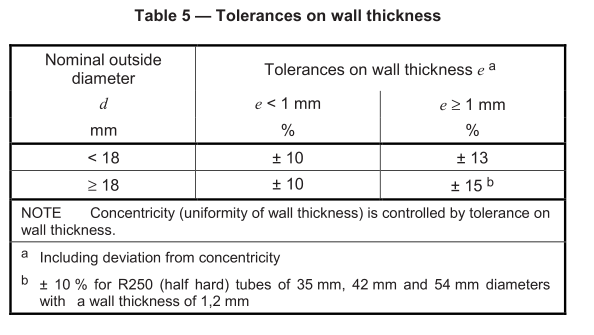

3.EN 1057 Copper Tubes Tolerances

Womic Steel ensures precise dimensional accuracy with the following tolerances:

4.EN 1057 Copper Tubes Chemical Composition

Our copper tubes are manufactured from Cu-DHP (CW024A) material with the following composition:

The composition shall conform to the following requirements:

Cu + Ag: min. 99,90 %;

0,015 %≤P≤0,040 %.

This copper grade is designated either Cu-DHP or CW024A.

This composition ensures excellent corrosion resistance, high thermal and electrical conductivity, and superior workability.

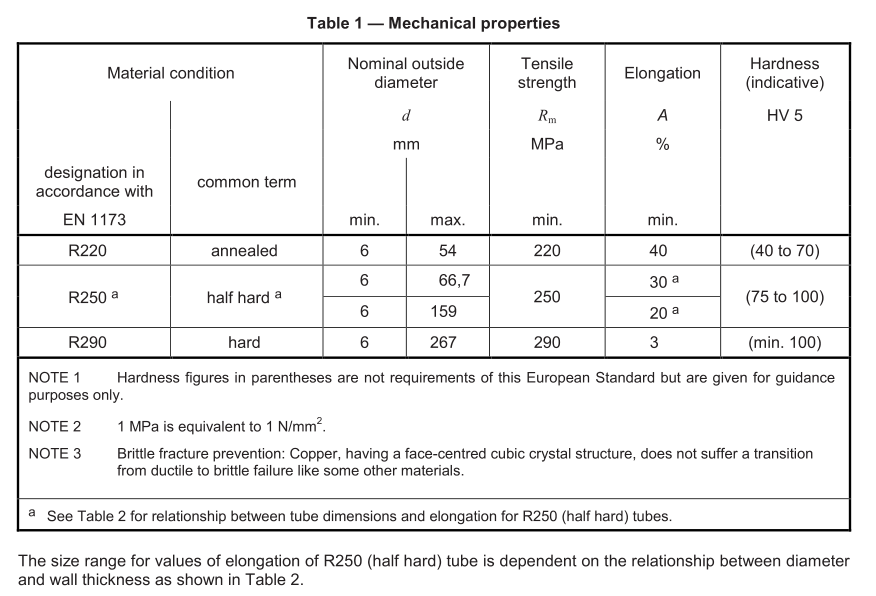

5.EN 1057 Copper Tubes Mechanical Properties

The mechanical properties of our EN 1057 copper tubes depend on the delivery condition:

6.EN 1057 Copper Tubes Delivery Conditions

Womic Steel provides EN 1057 copper tubes in the following tempers:

●R220 (Annealed): Highly flexible, suitable for bending and forming

●R250 (Half-Hard): Moderate strength, good balance of flexibility and durability

●R290 (Hard): High strength, suitable for straight applications with minimal bending

7.EN 1057 Copper Tubes Manufacturing Process

Our advanced production process ensures the highest quality standards:

1.Casting & Billet Preparation: High-purity copper is melted and cast into billets.

2.Extrusion & Piercing: Billets are extruded into tube form and pierced for the required dimensions.

3.Cold Drawing: Tubes are drawn through dies to achieve precise dimensions.

4.Annealing: Heat treatment is applied to achieve the required mechanical properties.

5.Straightening & Cutting: Tubes are straightened and cut to required lengths.

6.Inspection & Testing: Rigorous quality checks ensure compliance with EN 1057 standards.

8.Testing & Inspection

Womic Steel guarantees full quality control with comprehensive testing, including:

●Chemical/Spectrographic Analysis: Verification of material composition using chemical or spectroscopic methods.

●Tensile Test: Evaluation of tensile strength and elongation properties (EN 10002-1).

●Hardness Test: Measurement of material hardness via Vickers method (EN ISO 6507-1).

●Carbon Content Test: Quantitative determination of carbon percentage using EN 723 reference method.

●Carbon Film Test: Detection and assessment of carbon film presence (Annex B).

●Bending Test: Assessment of bendability under

●Drift-Expanding Test: Expansion of tube end by 30% with a 45°conical mandrel to validate ductility (EN ISO 8493).

●Flanging Test: Verification of flange formation (minimum 30% increase in tube diameter) using a tool with 1 mm corner radius (EN ISO 8494).

●Freedom from Defects Tests:

●Eddy Current Test (ECT): Detection of surface/subsurface defects (EN 1971 & Annex C.1).

●Hydrostatic Test: Pressure resistance validation via water pressure (Annex C.2).

●Pneumatic Test: Leakage detection using air/gas pressure (Annex C.3).

●Note: Initial type testing mandates ECT; other methods are manufacturer’s choice.

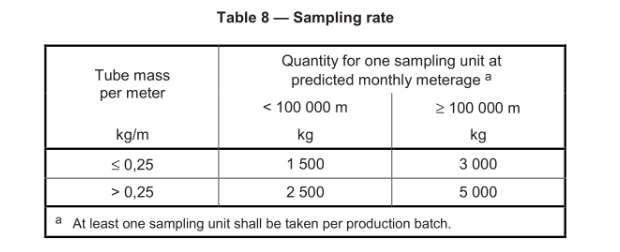

9.Sampling:

For the purpose of quality assurance during production, the number of sampling units to be taken at random shall be in accordance with Table 8.

These sampling rates shall apply when testing for dimensional controls; controls of other mandatory properties shall be carried out on each second sampling unit.

Results may be used from analyses carried out at an earlier stage of manufacturing the product, e.g. at the casting or billets inward stage, if product identity is maintained and if the quality management system of the manufacturer conforms to the relevant requirements of EN lSO 9001.

10.Packaging

To ensure safe handling and transportation, our copper tubes are packaged as follows:

●Anti-Oxidation Coating: A protective layer is applied to the surface of copper tubes to prevent oxidation and discoloration during storage and transportation.

●End Caps: Plastic or corrosion-resistant metal caps are installed on tube ends to prevent contamination and mechanical damage.

●Bundling: Tubes are grouped by specifications and securely fastened with high-strength plastic straps to minimize movement during transit.

●Wooden Crating: Bundled tubes are placed in moisture-resistant wooden crates. The crates are lined with waterproof foam or desiccant materials to prevent humidity damage and comply with ISPM 15 international phytosanitary standards.

●Reinforced Sealing: Crates are sealed with steel bands or heavy-duty fasteners. Optional shrink-wrapping is available for additional weatherproofing.

●Labeling: Each crate is labeled with the tube’s outer diameter (OD), wall thickness (WT), length, temper (e.g., soft, half-hard), production batch number, and date to ensure full traceability.

11.Transportation & Logistics

Womic Steel ensures timely and secure delivery of EN 1057 copper tubes:

●Sea Freight: Global shipments in containers with proper securing

●Rail or Road Transport: Reliable domestic and regional deliveries

●Climate-Controlled Transport: Available for sensitive applications

●Comprehensive Documentation: Shipping documents and insurance provided

●High Purity Copper: Exceptional durability and corrosion resistance

●Precision Manufacturing: Strict dimensional tolerances for reliable performance

●Custom Solutions: Tailored lengths, tempers, and coatings available

●Comprehensive Testing: Ensuring compliance with international standards

●Global Distribution: Reliable and timely worldwide delivery

12.Advantages of Choosing Womic Steel

13.Applications

EN 1057 copper tubes are widely used in:

- Plumbing Systems: Safe and reliable distribution of potable water

- Gas Distribution: Ideal for natural gas and LPG applications

- Heating Systems: Efficient performance in radiators and underfloor heating

- Refrigeration & Air Conditioning: High thermal conductivity for cooling systems

- Medical Gas Pipelines: Trusted in hospitals for oxygen and medical gases

Conclusion

Womic Steel’s EN 1057 Copper Tubes offer superior quality, strength, and reliability for plumbing, gas, and industrial applications. Our commitment to precision manufacturing, rigorous testing, and customer-focused solutions makes us a trusted partner in the industry.

Choose Womic Steel Group as your reliable partner for high-quality Copper Tubes&Fittings and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Mar-10-2025