Fittings

Pipe fitting is a piping system to connect, control, change direction, diversion, sealing, support and other parts of the role of the collective term.

Steel pipe fittings are pressurized pipe fittings. According to the different processing technology, divided into four categories, namely, butt-welding fittings (welded and non-welded two kinds), socket welding and threaded fittings, flange fittings.

Pipe fittings refers to the piping system for direct connection, turning, branching, reducing and used as end parts, etc..

Including elbows, tees, crosses, reducers, pipe hoops, internal and external threaded fittings, couplings, quick hose couplings, threaded short section, branch seat (table), plug (pipe plug), caps, blind plates, etc., excluding valves, flanges, fasteners, gaskets.

Pipe fittings of the material table contents are mainly style, connection form, pressure level, wall thickness level, material, norms and standards, specifications, etc..

Common Classification

There are many types of pipe fittings, which are categorized here according to use, connection, material, and processing.

According to the use of points

1, for the pipe connected to each other fittings: flanges, live, pipe hoops, clamp hoops, ferrules, throat hoops, etc.

2, change the direction of the pipe fittings: elbows, bends

3, change the pipe diameter of the pipe fittings: reducer (reducer), reducer elbow, branch pipe table, reinforcing pipe

4, increase the pipeline branch fittings: tee, cross

5, for pipe sealing fittings: gaskets, raw material tape, line hemp, flange blind, pipe plugs, blind, head, welded plugs

6、Fittings for pipe fixing: rings, tow hooks, rings, brackets, brackets, pipe cards, etc.

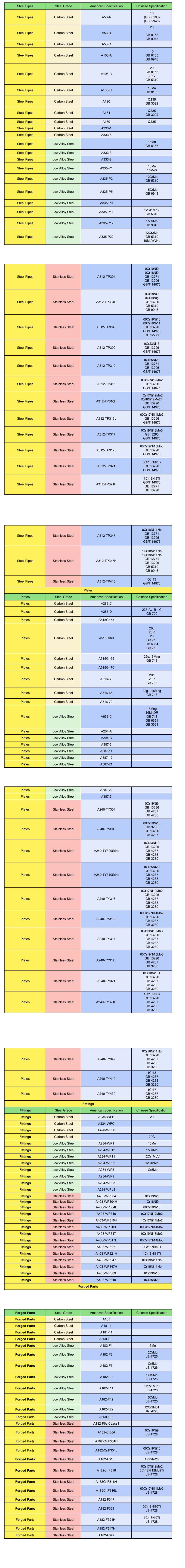

| Steel Pipes | Steel Grade | American Specification | Chinese Specification |

| Steel Pipes | Carbon Steel | A53-A | 10 (GB 8163) (GB 9948) |

| Steel Pipes | Carbon Steel | A53-B | 20GB 8163 GB 9948 |

| Steel Pipes | Carbon Steel | A53-C | |

| Steel Pipes | Carbon Steel | A106-A | 10 GB 8163 GB 9948 |

| Steel Pipes | Carbon Steel | A106-B | 20 GB 8163 20G GB 5310 |

| Steel Pipes | Carbon Steel | A106-C | 16Mn GB 8163 |

| Steel Pipes | Carbon Steel | A120 | Q235 GB 3092 |

| Steel Pipes | Carbon Steel | A134 | Q235 GB 3092 |

| Steel Pipes | Carbon Steel | A139 | Q235 |

| Steel Pipes | Carbon Steel | A333-1 | |

| Steel Pipes | Carbon Steel | A333-6 | |

| Steel Pipes | Low Alloy Steel | 16Mn GB 8163 |

|

| Steel Pipes | Low Alloy Steel | A333-3 | |

| Steel Pipes | Low Alloy Steel | A333-8 | |

| Steel Pipes | Low Alloy Steel | A335-P1 | 16Mo 15Mo3 |

| Steel Pipes | Low Alloy Steel | A335-P2 | 12CrMo GB 5310 |

| Steel Pipes | Low Alloy Steel | A335-P5 | 15CrMo GB 9948 |

| Steel Pipes | Low Alloy Steel | A335-P9 | |

| Steel Pipes | Low Alloy Steel | A335-P11 | 12Cr1MoV GB 5310 |

| Steel Pipes | Low Alloy Steel | A335-P12 | 15CrMo GB 9948 |

| Steel Pipes | Low Alloy Steel | A335-P22 | 12Cr2Mo GB 5310 10MoWvNb |

| Steel Pipes | Stainless Steel | A312-TP304 | 0Cr19Ni9 0Cr18Ni9 GB 12771 GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP304H | 0Cr18Ni9 0Cr19Nig GB 13296 GB 5310 GB 9948 |

| Steel Pipes | Stainless Steel | A312-TP304L | 00Cr19Ni10 00Cr19Ni11 GB 13296 GB/T 14976 GB 12771 |

| Steel Pipes | Stainless Steel | A312-TP309 | 0Cr23Ni13 GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP310 | 0Cr25Ni20 GB 12771 GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP316 | 0Cr17Ni12Mo2 GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP316H | 1Cr17Ni12Mo2 1Crl8Ni12Mo2Ti GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP316L | 00Cr17Ni14Mo2 GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP317 | 0Cr19Ni13Mo3 GB I3296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP317L | 00Cr19Ni13Mo3 GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP321 | 0Cr18Ni10Ti GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP321H | 1Cr18Ni9Ti GB/T 14976 GB 12771 GB 13296 |

| Steel Pipes | Stainless Steel | A312-TP347 | 0Cr18Ni11Nb GB 12771 GB 13296 GB/T 14976 |

| Steel Pipes | Stainless Steel | A312-TP347H | 1Cr18Ni11Nb 1Cr19Ni11Nb GB 12771 GB 13296 GB 5310 GB 9948 |

| Steel Pipes | Stainless Steel | A312-TP410 | 0Cr13 GB/T 14976 |

| Plates | |||

| Plates | Steel Grade | American Specification | Chinese Specification |

| Plates | Carbon Steel | A283-C | |

| Plates | Carbon Steel | A283-D | 235-A、B、C GB 700 |

| Plates | Carbon Steel | A515Gr.55 | |

| Plates | Carbon Steel | A515Gr60 | 20g 20R 20 GB 713 GB 6654 GB 710 |

| Plates | Carbon Steel | A515Gr.65 | 22g,16Mng GB 713 |

| Plates | Carbon Steel | A515Gr.70 | |

| Plates | Carbon Steel | A516-60 | 20g 20R GB 713 |

| Plates | Carbon Steel | A516-65 | 22g、16Mng GB 713 |

| Plates | Carbon Steel | A516-70 | |

| Plates | Low Alloy Steel | A662-C | 16Mng 16MnDR GB 713 GB 6654 GB 3531 |

| Plates | Low Alloy Steel | A204-A | |

| Plates | Low Alloy Steel | A204-B | |

| Plates | Low Alloy Steel | A387-2 | |

| Plates | Low Alloy Steel | A387-11 | |

| Plates | Low Alloy Steel | A387-12 | |

| Plates | Low Alloy Steel | A387-21 | |

| Plates | Low Alloy Steel | A387-22 | |

| Plates | Low Alloy Steel | A387-5 | |

| Plates | Stainless Steel | A240-TY304 | 0Cr19Ni9 GB 13296 GB 4237 GB 4238 |

| Plates | Stainless Steel | A240-TY304L | 00Cr19Ni10 GB 3280 GB 13296 GB 4237 |

| Plates | Stainless Steel | A240-TY309S(H) | 0Cr23Ni13 GB 13296 GB 4237 GB 4238 GB 3280 |

| Plates | Stainless Steel | A240-TY310S(H) | 0Cr25Ni20 GB 13296 GB 4237 GB 4238 GB 3280 |

| Plates | Stainless Steel | A240-TY316 | 0Cr17Ni12Mo2 GB 13296 GB 4237 GB 4238 GB 3280 |

| Plates | Stainless Steel | A240-TY316L | 00Cr17Ni14Mo2 GB 13296 GB 4237 GB 3280 |

| Plates | Stainless Steel | A240-TY317 | 0Cr19Ni13Mo3 GB 13296 GB 4237 GB 4238 GB 3280 |

| Plates | Stainless Steel | A240-TY317L | 00Cr19Ni13Mo3 GB 13296 GB 4237 GB 3280 |

| Plates | Stainless Steel | A240-TY321 | 0Cr18Ni10T GB 13296 GB 4237 GB 4238 GB 3280 |

| Plates | Stainless Steel | A240-TY321H | 1Cr18Ni9Ti GB 13296 GB 4237 GB 4238 GB 3280 |

| Plates | Stainless Steel | A240-TY347 | 0Cr18Ni11Nb GB 13296 GB 4237 GB 4238 GB 3280 |

| Plates | Stainless Steel | A240-TY410 | 1Cr13 GB 4237 GB 4238 GB 3280 |

| Plates | Stainless Steel | A240-TY430 | 1Cr17 GB 4237 GB 3280 |

| Fittings | |||

| Fittings | Steel Grade | American Specification | Chinese Specification |

| Fittings | Carbon Steel | A234-WPB | 20 |

| Fittings | Carbon Steel | A234-WPC | |

| Fittings | Carbon Steel | A420-WPL6 | |

| Fittings | Carbon Steel | 20G | |

| Fittings | Low Alloy Steel | A234-WP1 | 16Mo |

| Fittings | Low Alloy Steel | A234-WP12 | 15CrMo |

| Fittings | Low Alloy Steel | A234-WP11 | 12Cr1MoV |

| Fittings | Low Alloy Steel | A234-WP22 | 12Cr2Mo |

| Fittings | Low Alloy Steel | A234-WP5 | 1Cr5Mo |

| Fittings | Low Alloy Steel | A234-WP9 | |

| Fittings | Low Alloy Steel | A234-WPL3 | |

| Fittings | Low Alloy Steel | A234-WPL8 | |

| Fittings | Stainless Steel | A403-WP304 | 0Cr19Nig |

| Fittings | Stainless Steel | A403-WP304H | 1Cr18Ni9 |

| Fittings | Stainless Steel | A403-WP304L | 00Cr19Ni10 |

| Fittings | Stainless Steel | A403-WP316 | 0Cr17Ni12Mo2 |

| Fittings | Stainless Steel | A403-WP316H | 1Cr17Ni14Mo2 |

| Fittings | Stainless Steel | A403-WP316L | 00Cr17Ni14Mo2 |

| Fittings | Stainless Steel | A403-WP317 | 0Cr19Ni13Mo3 |

| Fittings | Stainless Steel | A403-WP317L | 00Cr17Ni14Mo3 |

| Fittings | Stainless Steel | A403-WP321 | 0Cr18Ni10Ti |

| Fittings | Stainless Steel | A403-WP321H | 1Cr18Ni11Ti |

| Fittings | Stainless Steel | A403-WP347 | 0Cr19Ni11Nb |

| Fittings | Stainless Steel | A403-WP347H | 1Cr19Ni11Nb |

| Fittings | Stainless Steel | A403-WP309 | 0Cr23Ni13 |

| Fittings | Stainless Steel | A403-WP310 | 0Cr25Ni20 |

| Forged Parts | |||

| Forged Parts | Steel Grade | American Specification | Chinese Specification |

| Forged Parts | Carbon Steel | A105 | |

| Forged Parts | Carbon Steel | A181-1 | |

| Forged Parts | Carbon Steel | A181-11 | |

| Forged Parts | Carbon Steel | A350-LF2 | |

| Forged Parts | Low Alloy Steel | A182-F1 | 16Mo |

| Forged Parts | Low Alloy Steel | A182-F2 | 12CrMo JB 4726 |

| Forged Parts | Low Alloy Steel | A182-F5 | 1Cr5Mo JB 4726 |

| Forged Parts | Low Alloy Steel | A182-F9 | 1Cr9Mo JB 4726 |

| Forged Parts | Low Alloy Steel | A182-F11 | 12Cr1MoV JB 4726 |

| Forged Parts | Low Alloy Steel | A182-F12 | 15CrMo JB 4726 |

| Forged Parts | Low Alloy Steel | A182-F22 | 12Cr2Mo1 .IR 4726 |

| Forged Parts | Low Alloy Steel | A350-LF3 | |

| Forged Parts | Stainless Steel | A182-F6a CLass1 | |

| Forged Parts | Stainless Steel | A182-Cr304 | 0Cr18Ni9 JB 4728 |

| Forged Parts | Stainless Steel | A182-Cr.F304H | |

| Forged Parts | Stainless Steel | A182-Cr.F304L | 00Cr19Ni10 JB 4728 |

| Forged Parts | Stainless Steel | A182-F310 | Cr25Ni20 |

| Forged Parts | Stainless Steel | A182Cr.F316 | 0Cr17Ni12Mo2 0Cr18Ni12Mo2Ti JB 4728 |

| Forged Parts | Stainless Steel | A182Cr.F316H | |

| Forged Parts | Stainless Steel | A182Cr.F316L | 00Cr17Ni14Mo2 JB 4728 |

| Forged Parts | Stainless Steel | A182-F317 | |

| Forged Parts | Stainless Steel | A182-F321 | 0Cr18Ni10Ti JB 4728 |

| Forged Parts | Stainless Steel | A182-F321H | 1Cr18Ni9Ti JB 4728 |

| Forged Parts | Stainless Steel | A182-F347H | |

| Forged Parts | Stainless Steel | A182-F347 | |

According to the connection points

1、Welded fittings

2、Threaded fittings

3、Tubing fittings

4、Clamping fittings

5、Socket fittings

6、Bonded fittings

7、Hot melt fittings

8, Curved bullet double fusion fittings

9、Glue ring connecting fittings

According to the material points

1, cast steel fittings: ASTM/ASME A234 WPB, WPC

2、Cast iron pipe fittings

3、Stainless steel fittings

ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

astm/asme a403 wp 321-321h astm/asme a403 wp 347-347h

Low Temperature Steels: ASTM/ASME A402 WPL3-WPL 6

High Performance Steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon-chrome asphalt, PVC, PPR, RFPP (reinforced polypropylene), etc.

4、Plastic pipe fittings

5、PVC pipe fittings

6 、Rubber pipe fittings

7、Graphite pipe fittings

8、Forged steel fittings

9、PPR pipe fittings

10, alloy pipe fittings: ASTM / ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP911, 15Mo3 15CrMoV, 35CrMoV

11、PE pipe fittings

12、ABS pipe fittings

According to the production method

Can be divided into pushing, pressing, forging, casting and so on.

According to manufacturing standards

Can be divided into national standard, electric standard, ship standard, chemical standard, water standard, American standard, German standard, Japanese standard, Russian standard and so on.

According to the radius of curvature to points

Can be divided into long radius elbow and short radius elbow. Long radius elbow means that its radius of curvature is equal to 1.5 times the outside diameter of the pipe, that is, R = 1.5D; short radius elbow means that its radius of curvature is equal to the outside diameter of the pipe, that is, R = 1.0D. (D is the diameter of the elbow, R is the radius of curvature).

If divided by pressure rating

There are about seventeen, and the U.S. pipe standard is the same, there are: Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS; Sch80, SCH100, Sch120, Sch140, Sch160, XXS; which is most commonly used are STD and XS.

Patterns and Designations

Elbows

Elbow is to make the pipe turn the pipe fittings EL Elbow

1、Reducing elbow Elbow with different diameters at both ends

REL Reducing elbow

2, long radius elbow bend radius equal to 1.5 times the nominal size of the pipe elbow

ELL (LR) (EL) Long radius elbow

3, short radius elbow bend radius equal to the nominal size of the pipe elbow

ELS (SR) (ES) Short radius elbow

4, 45 ° elbow so that the pipe turned 45 ° elbow

5, 90 ° elbow so that the pipe to 90 ° elbow

6, 180 ° elbow (back elbow) to make the pipe turn 180 ° elbow

7、Seamless elbow with seamless steel pipe processing elbow

8, welded elbow (seam elbow) with a steel plate formed and welded into the elbow

9, oblique elbow (shrimp waist elbow) by trapezoidal pipe section welded elbow shaped like shrimp waist

MEL Mitre elbow

Tube Bending

Bending a tube into a section of pipe with the desired curvature at room temperature or under heating conditions.

fabricated pipe bend

Cross-over bend

Offset bend

Quarter bend

Cirele bend

Single offset quarter bend

“S”bend

Single offset“U”bend

“U”bend

Double offset expansion“U”bend

Mitre bend

3-piece mitre bend

Corrugated bend

Tee

A kind of pipe fittings that can be connected to three different directions of pipelines, in the form of T-shaped, Y-shaped pipe fittings.

Equal diameter tee with the same diameter tee.

Reduced diameter tee with different diameters.

Tee

LT Lateral tee

RT Reducing tee

Equal tee 45°Y Type

Reducing tee 45° Y Type

Cross

A cross-shaped fitting that connects pipes in four different directions. cross

CRS straight cross

CRR reducing cross

Reducing cross (reducing on one outlet)

Reducing cross (reducing on one run and outlet)

Reducing cross (reducing on both outlet)

Reducing cross (reducing on one run and both outlet)

Reducers

Straight pipe fittings with different diameters at both ends.

Concentric Reducer (Concentric Size Head) Reducer with overlapping centerline

Eccentric Reducer (Eccentric Size Head) Reducer with non-coincident centerline and one side straight.

Reducer

Concentric reducer

Eccentric reducer

Pipe clamps

Fittings with internal threads or sockets for connecting two pipe sections.

Double threaded pipe clamps Pipe clamps with threads on both ends.

Single-threaded pipe clamps Threaded pipe clamp at one end.

Double socket hose clamps Hose clamps with sockets at both ends.

Single socket hose clamp with socket on one end.

Reducing double socket hose clamps Hose clamps with sockets at both ends and different diameters.

Reducing Threaded Couplings Couplings with internal threads on both ends and different diameters.

CPL Coupling

FCPL Full coupling

HCPL Half coupling

RCPL Reducing coupling

Full thread coupling

Half Cplg half thread coupling

Female and male threaded fittings (internal and external threads)

Pipe fittings for connecting pipes of different diameters with one end having a female thread and the other end having a male thread.

BU Female and male threaded fittings Bushing

HHB Hexagonal head

FB Flat fitting

Loose couplings Hose couplings

A hose coupling consisting of several elements for connecting pipe segments and facilitating the assembly and disassembly of other fittings, valves, etc. on the pipeline.

Hose couplings are fittings that allow for quick connection of hoses.

UN Union

HC Hose coupler

Hose couplers are straight fittings with a male thread.

Single threaded nipple A nipple with a male thread at one end.

Double threaded nipple A nipple with male threads at both ends.

Reduced diameter nipple Nipple with different diameters at both ends.

SE Stub end

NIP Pipe nipple or straight nipple

SNIP Swaged nipple

NPT=National pipe thread = American Standard Thread

BBE Bevel both ends

BLE Bevel large end

BSE Bevel small end Bevel small end

PBE Plain both ends Plain both ends

PLE Plain large end large end

PSE Plain small end small end

POE Plain one end

TOE Thread one end -Thread both ends

TBE Thread both ends

TLE Thread large end

TSE Thread small end Small end thread

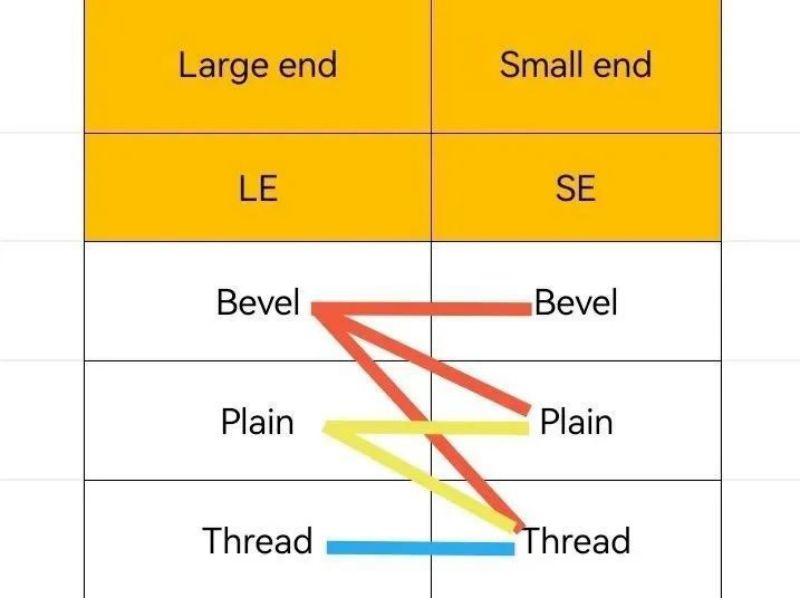

Reducing fittings end combination form

Olet

TOL Threaded pipe supports threadolet

WOL Welded pipe stand weldolet

SOL Socket branch sockolet

Elbow stand elbolet

Elbow stand elbolet

Plugs (pipe plugs) caps

Silk plug used to plug the pipe end of the external threaded pipe fittings, square head pipe plugs, hexagonal pipe plugs, etc..

Pipe cap is welded or threaded with the end of the pipe connected to the cap-shaped pipe fittings.

CP Pipe Cap(Head) Cap

PL pipe plug (silk plug) Plug

HHP Hex Head PLUG

RHP Round head plug

SHP Square head plug

Blind Plate

A circular plate inserted between a pair of flanges to separate pipes.

Gasket ring hollow partition, generally used when not isolated.

BLK Blank A bulkhead resembling a figure of 8. Half of the figure of 8 is solid and used to separate pipes, and the other half is hollow and used when not separating pipes.

BLK Blank

SB 8-word blind Spectacle blind (blank)

Connection form

BW Butt weIding

SW SocKet welding

Pressure Rating

CL Class

PN Nominal pressure

Wall Thickness Grades

THK Wall Thickness Thickness

SCH Schedule number

STD Standard

XS Extra strong

XXS Double extra strong

Tube Series Standards

The U.S. pipe series (ANSIB36.10 and ANSIB36.19) is a typical “large outside diameter series”, the nominal size range of DN6 ~ DN2000mm.

First, the pipe labeling “SCH” that the wall thickness.

① ANSI B36.10 standard includes SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140, SCH160 ten levels.

② ANSI B36.19 standard includes SCH5s, SCH10s, SCH40s, SCH80s four grades.

Secondly, the pipe wall thickness is expressed in terms of pipe weight, which divides the pipe wall thickness into three types:

Standard weight pipe, indicated by STD;

Thickened pipe, indicated by XS;

Extra thick tube, indicated by XXS.

Steel Grade

Norms and standards

There are two main systems of international pipe flange standards, namely, the European pipe flange system represented by German DIN (including the former Soviet Union) and the American pipe flange system represented by American ANSI pipe flange. In addition, there is the Japanese JIS pipe flange, but in the petrochemical plant is generally used only for public works, and in the international influence is small. Now the countries pipe flange profile below:

1, Germany and the former Soviet Union as the representative of the European system pipe flange

2, the American system pipe flange standard, to ANSI B16.5 and ANSI B 16.47

3,the British and French pipe flange standards, the two countries have two sets of pipe flange standards.

In summary, the international common pipe flange standard can be summarized as two different, and can not be interchangeable pipe flange system: a Germany as the representative of the European pipe flange system; the other is the United States as the representative of the American pipe flange system.

IOS7005-1 is a standard issued by the International Organization for Standardization in 1992, which is actually a pipe flange standard that combines two sets of pipe flanges from the United States and Germany.

Post time: Nov-15-2023