1. Standard: SANS 719

2. Grade: C

3. Type: Electric Resistance Welded (ERW)

4. Size Range:

- Outer Diameter: 10mm to 610mm

- Wall Thickness: 1.6mm to 12.7mm

5. Length: 6 meters, or as required

6. Ends: Plain end, beveled end

7. Surface Treatment:

- Black (self-colored)

- Oiled

- Galvanized

- Painted

8. Applications: Water, sewage, general conveyance of fluids

9. Chemical Composition:

- Carbon (C): 0.28% max

- Manganese (Mn): 1.25% max

- Phosphorus (P): 0.040% max

- Sulfur (S): 0.020% max

- Silcon (Si): 0.04 % max. Or 0.135 % to 0.25 %

10. Mechanical Properties:

- Tensile Strength: 414MPa min

- Yield Strength: 290 MPa min

- Elongation: 9266 divided by numerical value of actual UTS

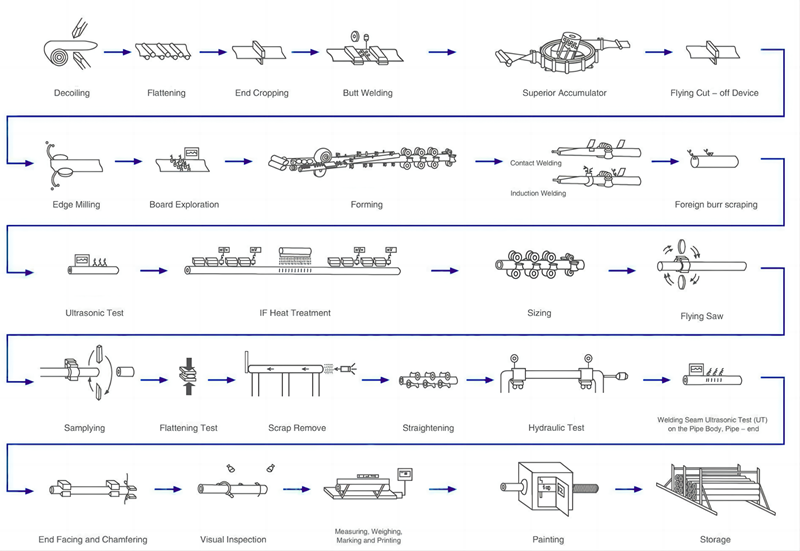

11. Manufacturing Process:

- The pipe is manufactured using cold-formed and high-frequency induction welded (HFIW) process.

- The strip is formed into a tubular shape and welded longitudinally using high-frequency induction welding.

12. Inspection and Testing:

- Chemical analysis of the raw material

- Transverse tensile test to ensure mechanical properties comply with specifications

- Flattening test to ensure the pipe's ability to withstand deformation

- Root bend test (electric fusion welds) to ensure the pipe's flexibility and integrity

- Hydrostatic test to ensure the pipe's leak-tightness

13. Non-Destructive Testing (NDT):

- Ultrasonic testing (UT)

- Eddy current testing (ET)

14. Certification:

- Mill test certificate (MTC) according to EN 10204/3.1

- Third-party inspection (optional)

15. Packaging:

- In bundles

- Plastic caps on both ends

- Waterproof paper or steel sheet cover

- Marking: as required (including Manufacturer,grade, size, standard, heat number, Lot Number etc.)

16. Delivery Condition:

- As rolled

- Normalized

- Normalized rolled

17. Marking:

- Each pipe should be legibly marked with the following information:

- Manufacturer's name or trademark

- SANS 719 Grade C

- Size (outer diameter and wall thickness)

- Heat number or batch number

- Date of manufacture

- Inspection and test certificate details

18. Special Requirements:

- Pipes can be supplied with special coatings or linings for specific applications (e.g., epoxy coating for corrosion resistance).

19. Additional Tests (If Required):

- Charpy V-notch impact test

- Hardness test

- Macrostructure examination

- Microstructure examination

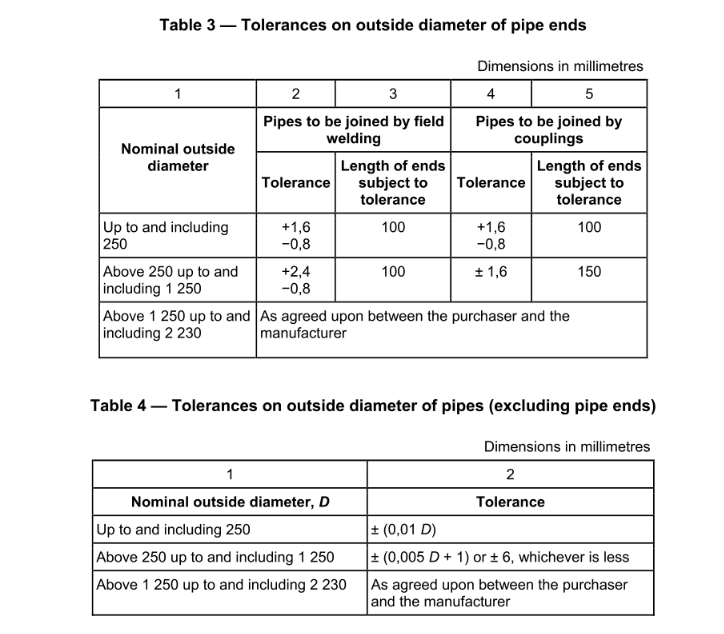

20.Tolerance:

-Outside Diameter

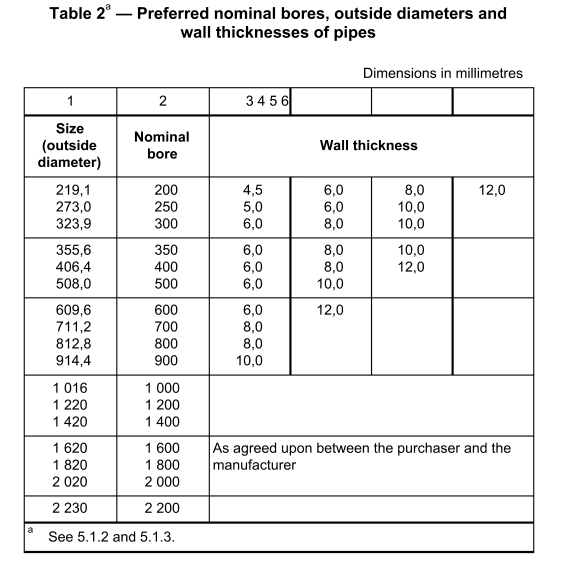

-Wall thickness

The wall thickness of a pipe shall, subject to a tolerance of +10 % or -8 %, be one of the relevant values given in columns 3 to 6 of below table, unless otherwise agreed upon between the manufacturer and the purchaser.

-Straightness

Any deviation of a pipe from a straight line, shall not exceed 0,2 % of the length of the pipe.

Any out-of-roundness (other than that caused by sag), of pipes of outside diameter greater than 500 mm shall not exceed 1 % of the outside diameter (i.e.maximum ovality 2 %) or 6 mm, whichever is less.

Please note that this detailed data sheet provides comprehensive information about SANS 719 Grade C pipes. Specific requirements may vary based on the project and the exact specification of the pipe required.

Post time: Apr-28-2024