As the saying goes, “three parts paint, seven parts coating”, and the most important thing in the coating is the quality of the surface treatment of the material, a relevant study shows that the influence of the coating quality factors in the quality of the surface treatment of the material accounted for the ratio of 40-50% of the more. The role of surface treatment in coating can be imagined.

Descaling grade: refers to the cleanliness of surface treatment.

Steel Surface Treatment Standards

|

GB 8923-2011 |

Chinese National Standard |

|

ISO 8501-1:2007 |

ISO Standard |

|

SIS055900 |

Sweden Standard |

|

SSPC-SP2,3,5,6,7,AND 10 |

Surface Treatment Standards of the American Steel Structure Painting Association |

|

BS4232 |

British Standard |

|

DIN55928 |

Germany Standard |

|

JSRA SPSS |

Japan Shipbuilding Research Association Standards |

★ National standard GB8923-2011 describes the descaling grade ★

[1] Jet or blast descaling

Jet or blast descaling is indicated by the letter “Sa”. There are four descaling grades:

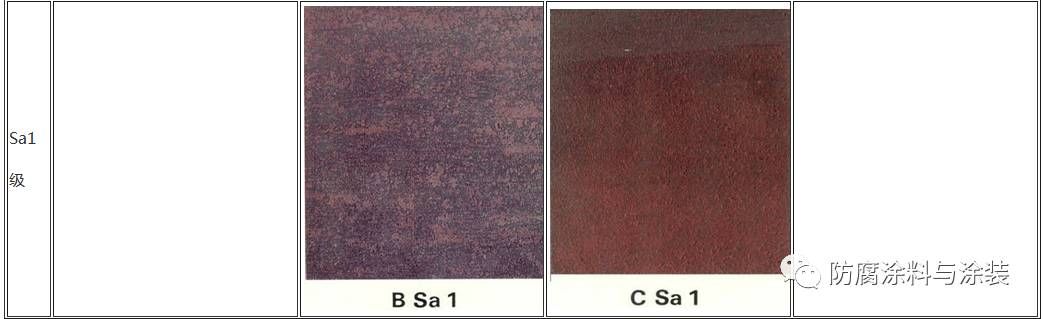

Sa1 Light Jet or Blast Descaling

Without magnification, the surface should be free of visible grease and dirt, and free of adhesions such as poorly adhered oxidized skin, rust and paint coatings.

Sa2 Thorough Jet or Blast Descaling

Without magnification, the surface shall be free from visible grease and dirt and oxygen virtually free from oxidized skin, rust, coatings and foreign impurities, the residue of which shall be firmly attached.

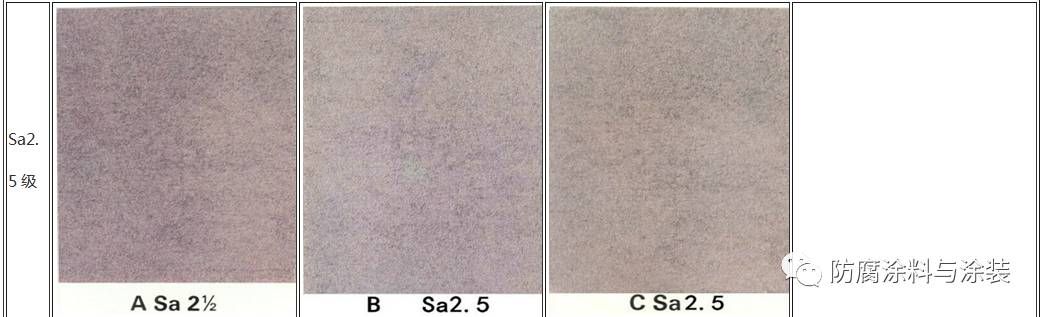

Sa2.5 Very Thorough Jet or Blast Descaling

Without magnification, the surface should be free of visible grease, dirt, oxidation, rust, coatings and foreign impurities, and the residual traces of any contaminants should be only dotted or streaked with light discoloration.

Sa3 Jet or blast descaling of steel with clean surface appearance

Without magnification, the surface shall be free from visible oil, grease, dirt, oxidized skin, rust, coatings and foreign impurities, and the surface shall have a uniform metallic color.

[2] Hand and power tool descaling

Hand and power tool descaling is indicated by the letter “St”. There are two classes of descaling:

St2 Thorough hand and power tool descaling

Without magnification, the surface shall be free from visible oil, grease and dirt, and free from poorly adhered oxidized skin, rust, coatings and foreign impurities.

St3 Same as St2 but more thorough, the surface should have the metallic luster of the substrate.

【3】Flame cleaning

Without magnification, the surface shall be free of visible oil, grease, dirt, oxidized skin, rust, coatings and foreign impurities, and any residual traces shall be only surface discoloration.

Comparison table between our descaling standard and foreign descaling standard equivalent

Note: Sp6 in SSPC is slightly stricter than Sa2.5, Sp2 is manual wire brush descaling and Sp3 is power descaling.

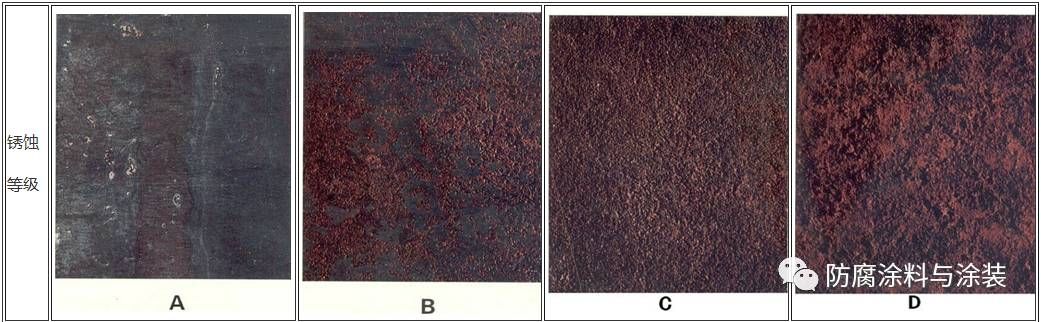

Comparison charts of steel surface corrosion grade and jet descaling grade are as follows:

Post time: Dec-05-2023