Overview of Alloy Materials

Definition of Alloy

An alloy is a homogeneous mixture composed of two or more metals, or a combination of metals and non-metallic elements, with metallic characteristics. The concept behind alloy design is to combine elements in such a way as to optimize mechanical, physical, and chemical properties to meet the specific requirements of different applications.

Classification of Alloy Materials

Alloy materials can be classified based on their main constituent elements and properties as follows:

●Ferrous Alloys: These are iron-based alloys with added elements like carbon, manganese, and silicon, mainly used in the steelmaking and casting industries.

●Aluminum Alloys: These are aluminum-based alloys with elements like copper, magnesium, and zinc, known for being lightweight, strong, and having excellent conductivity and thermal properties.

●Copper Alloys: These are copper-based alloys with added elements like zinc, tin, and lead, offering good conductivity, corrosion resistance, and workability.

●Magnesium Alloys: Magnesium-based alloys, usually combined with aluminum, zinc, and manganese, are the lightest structural metals with good shock resistance and heat dissipation.

●Nickel Alloys: Nickel-based alloys contain elements such as chromium, iron, and cobalt, and exhibit outstanding corrosion resistance and high-temperature performance.

●Titanium Alloys: Known for their high strength, low density, and exceptional corrosion resistance, titanium-based alloys are widely used in aerospace applications.

Ferrous Alloys

Composition and Properties of Ferrous Alloys

Ferrous alloys are composed of iron with various alloying elements that enhance their mechanical properties. Common elements include:

●Carbon: One of the most important alloying elements, varying carbon content in ferrous alloys affects hardness and toughness. High-carbon alloys offer more hardness but less toughness.

●Silicon: Silicon improves the strength and toughness of ferrous alloys and is often used in silicon-iron alloys for steelmaking as a deoxidizer and alloying agent.

●Manganese: Manganese is crucial for increasing the strength and hardness of ferrous alloys, and ferromanganese alloys are essential for improving the wear resistance and corrosion resistance of steel.

●Chromium: Chromium-iron alloys provide excellent corrosion resistance and high-temperature strength, commonly used in the production of stainless steel and special steels.

Applications of Ferrous Alloys

Ferrous alloys are widely used across various industries, including:

●Steelmaking Industry: Ferrous alloys are important additives in steel production, used to modify steel’s composition and improve its properties.

●Casting Industry: In casting processes, ferrous alloys enhance the mechanical properties and durability of cast iron products.

●Welding Materials: Ferrous alloys are used in the production of welding rods and flux to ensure high-quality weld joints.

●Chemical and Fertilizer Industries: Ferrous alloys serve as catalysts and reducing agents in chemical and fertilizer manufacturing.

●Metalworking: Ferrous alloys are used in tools like cutting instruments and molds, improving their durability and efficiency.

Aluminum Alloys

Key Characteristics of Aluminum Alloys

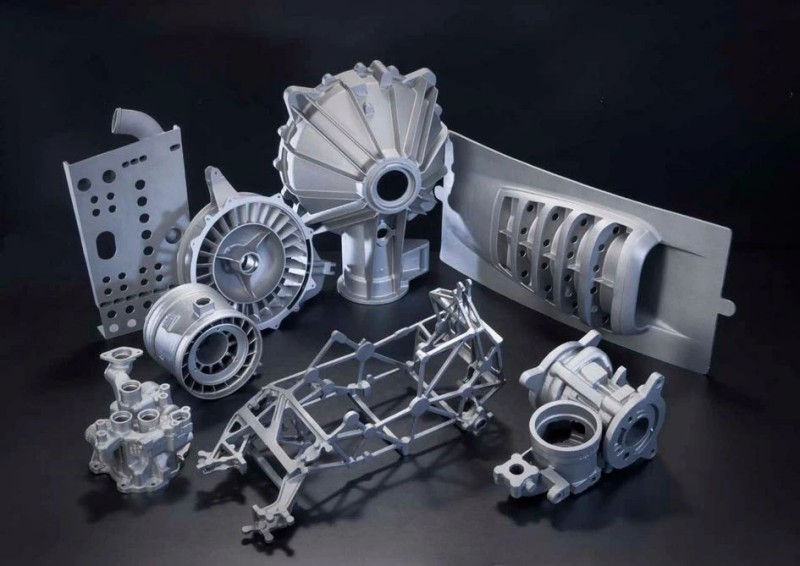

Aluminum alloys are renowned for their lightweight, high strength, and ease of processing, making them essential in modern industries. Key characteristics include:

●Lightweight: Aluminum alloys have a low density of approximately 2.7 g/cm³, making them ideal for applications requiring weight reduction.

●High Strength: Through alloying and heat treatment, aluminum alloys can achieve high tensile strength, with some alloys exceeding 500 MPa.

●Excellent Conductivity: Pure aluminum is an excellent conductor of electricity and heat, and aluminum alloys retain a significant portion of these properties.

●Corrosion Resistance: A natural oxide layer forms on the surface of aluminum alloys, providing excellent corrosion resistance, and special treatments can further enhance this property.

●Ease of Processing: Aluminum alloys exhibit good plasticity, making them suitable for casting, extrusion, and forging processes.

Grades and Applications of Aluminum Alloys

Aluminum alloys are classified based on their main alloying elements and properties. Some common grades include:

●1xxx Series: Pure aluminum, with over 99.00% aluminum content, primarily used in the electrical industry and everyday consumer goods.

●2xxx Series: Copper is the primary alloying element, significantly improving strength after heat treatment, commonly used in aerospace applications.

●3xxx Series: Manganese is the main alloying element, offering good corrosion resistance, widely used in construction and structural materials.

●4xxx Series: Silicon is the main alloying element, providing heat resistance and good welding properties, suitable for welding materials and heat-resistant components.

●5xxx Series: Magnesium is the primary alloying element, offering excellent mechanical properties and corrosion resistance, used in marine, automotive, and aerospace industries.

●6xxx Series: Magnesium and silicon are the main alloying elements, providing good strength and workability, commonly used in structural materials.

●7xxx Series: Zinc is the primary alloying element, and these alloys offer the highest strength, commonly used in aircraft structures and high-strength applications.

●8xxx Series: Contain other elements like iron and nickel, offering good strength and conductivity, mainly used in the electrical industry.

Aluminum alloys are used in various sectors, including:

●Aerospace: Lightweight and high-strength aluminum alloys are essential for aircraft structures and components.

●Transportation: Aluminum alloys are used to manufacture lightweight automotive and railway components, improving fuel efficiency.

●Electrical Industry: Aluminum is a preferred material for cables and transformers

●Construction: Aluminum alloys are widely used in architectural structures, window frames, doors, and roofing due to their strength, corrosion resistance, and aesthetic appearance.

●Packaging: Aluminum alloys, particularly in the form of foils and cans, are used extensively in the packaging industry because they are lightweight, non-toxic, and highly recyclable.

Copper Alloys

Composition and Properties of Copper Alloys

Copper alloys are known for their excellent electrical and thermal conductivity, corrosion resistance, and ease of fabrication. Common copper alloys include:

●Brass (Copper-Zinc Alloy): Known for its strength, ductility, and resistance to corrosion, brass is commonly used in mechanical applications, plumbing, and musical instruments.

●Bronze (Copper-Tin Alloy): This alloy offers superior corrosion resistance, hardness, and wear resistance, often used in bearings, bushings, and marine applications.

●Copper-Nickel Alloys: These alloys provide excellent corrosion resistance in marine environments, making them ideal for shipbuilding, offshore platforms, and desalination plants.

●Beryllium Copper: With high strength, hardness, and corrosion resistance, beryllium copper is often used in precision instruments, electrical connectors, and springs.

Applications of Copper Alloys

Copper alloys serve a broad range of industries due to their versatility and unique properties:

●Electrical Industry: Copper alloys are widely used in electrical connectors, wiring, and components due to their excellent conductivity.

●Plumbing and Fluid Handling: Brass and bronze are commonly used for valves, fittings, and other plumbing applications because of their corrosion resistance.

●Marine Industry: Copper-nickel alloys are favored for marine applications due to their excellent resistance to seawater corrosion.

●Precision Engineering: Beryllium copper is used in tools, non-sparking equipment, and precision components because of its strength and durability.

Magnesium Alloys

Characteristics of Magnesium Alloys

Magnesium alloys are the lightest structural metals, with an excellent strength-to-weight ratio, shock absorption, and machinability. Key properties include:

●Lightweight: Magnesium alloys are 35% lighter than aluminum and 78% lighter than steel, making them ideal for weight-sensitive applications.

●Good Machinability: Magnesium alloys have excellent machinability, allowing for complex and precise parts to be made efficiently.

●Shock Absorption: These alloys have good shock absorption properties, making them useful in automotive and aerospace applications.

●Heat Dissipation: Magnesium alloys provide effective heat dissipation, crucial for electronics and high-temperature components.

Applications of Magnesium Alloys

Due to their lightweight and strength, magnesium alloys are used in various industries:

●Automotive Industry: Magnesium alloys are used in engine components, transmission housings, and wheels to reduce vehicle weight and improve fuel efficiency.

●Aerospace Industry: Magnesium alloys are employed in aircraft parts and aerospace components where weight reduction is critical.

●Electronics: Magnesium alloys are used in the manufacture of lightweight laptops, cameras, and mobile phones due to their strength and heat dissipation properties.

●Medical Devices: Magnesium alloys are used in bioresorbable implants and orthopedic devices due to their biocompatibility.

Nickel Alloys

Properties of Nickel Alloys

Nickel alloys are known for their exceptional corrosion resistance, high-temperature stability, and mechanical strength. They are typically alloyed with chromium, iron, and other elements to enhance performance in extreme environments. Key properties include:

●Corrosion Resistance: Nickel alloys have excellent resistance to oxidation and corrosion in harsh environments, including seawater and acidic conditions.

●High-Temperature Strength: Nickel alloys retain their strength at high temperatures, making them suitable for use in aerospace and power generation applications.

●Wear Resistance: Nickel alloys offer good wear resistance, which is valuable in applications requiring long-lasting durability.

Applications of Nickel Alloys

Nickel alloys are used in demanding applications across various sectors:

●Aerospace Industry: Nickel-based superalloys are used in jet engines, turbine blades, and other high-temperature components because of their heat resistance.

●Chemical Processing: Nickel alloys are used in reactors, heat exchangers, and piping systems where resistance to corrosion and high temperatures is essential.

●Power Generation: Nickel alloys are employed in nuclear reactors and gas turbines due to their high-temperature capabilities and corrosion resistance.

●Marine Industry: Nickel alloys are used in marine environments for applications like pumps, valves, and seawater desalination equipment.

Titanium Alloys

Characteristics of Titanium Alloys

Titanium alloys are lightweight yet strong, with exceptional resistance to corrosion and high-temperature stability. Key properties include:

●High Strength-to-Weight Ratio: Titanium alloys are as strong as steel but nearly 45% lighter, making them ideal for aerospace and high-performance applications.

●Corrosion Resistance: Titanium alloys offer outstanding resistance to corrosion, especially in seawater and chemical environments.

●Biocompatibility: Titanium alloys are biocompatible, making them suitable for medical implants and devices.

●High-Temperature Stability: Titanium alloys can withstand extreme temperatures, maintaining their strength and integrity in aerospace and industrial applications.

Applications of Titanium Alloys

Titanium alloys are widely used in industries where high strength, lightweight, and corrosion resistance are critical:

●Aerospace Industry: Titanium alloys are used in aircraft frames, engine components, and landing gears due to their high strength and weight savings.

●Medical Devices: Titanium alloys are used in orthopedic implants, dental implants, and surgical instruments due to their biocompatibility and durability.

●Marine Industry: Titanium alloys are employed in subsea components, shipbuilding, and offshore drilling due to their corrosion resistance.

●Industrial Applications: Titanium alloys are used in chemical processing plants, power generation, and automotive applications for components requiring strength and corrosion resistance.

Conclusion

Alloy materials play a pivotal role in modern industries, offering tailored solutions with unique combinations of strength, weight, corrosion resistance, and durability. From aerospace to automotive, construction to medical devices, the versatility of alloy materials makes them indispensable for countless applications. Whether it’s the high strength of ferrous alloys, the lightweight properties of aluminum alloys, or the corrosion resistance of nickel and titanium alloys, alloys are engineered to meet the diverse needs of today’s technologically advanced world.

Post time: Oct-17-2024