Chemical piping and valves are an indispensable part of chemical production and are the link between various types of chemical equipment. How do the 5 most common valves in chemical piping work? The main purpose? What are the chemical pipes and fittings valves? (11 kinds of pipe + 4 types of fittings + 11 valves) chemical piping these things, a full grasp!

3

11 major valves

The device used to control the flow of fluid in the pipeline is called a valve. Its main roles are:

Open and close the role – cut off or communicate with the fluid flow in the pipeline;

Adjustment – to adjust the fluid flow rate in the pipeline, flow;

Throttling – fluid flow through the valve, resulting in a large pressure drop.

Classification:

According to the role of the valve in the pipeline is different, can be divided into cut-off valve (also known as globe valve), throttle valve, check valve, safety valves and so on;

According to the different structural forms of valves can be divided into gate valves, plug (often called Cocker), ball valves, butterfly valves, diaphragm valves, lined valves and so on.

In addition, according to the production of different materials for the valve, and is divided into stainless steel valves, cast steel valves, cast iron valves, plastic valves, ceramic valves and so on.

Various valve selection can be found in the relevant manuals and samples, only the most common types of valves are introduced here.

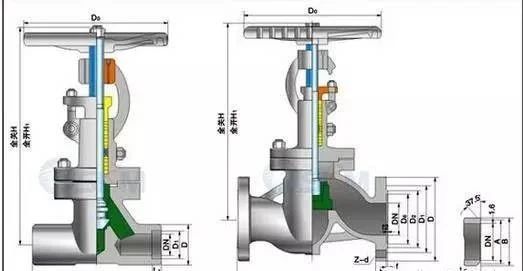

①Globe Valve

Because of the simple structure, easy to manufacture and maintain, widely used in low and medium pressure pipelines. It is installed in the valve stem below the round valve disc (valve head) and the valve body flange part (valve seat) to achieve the purpose of cutting off fluid flow.

The valve stem can be adjusted by the thread lift the valve opening degree, play a certain role in regulation. Due to the valve’s cut-off effect is to rely on the valve head and seat plane contact seal, not suitable for use in the pipeline containing solid particles of fluid.

Globe Valve can be used according to the characteristics of the media to choose the appropriate valve head, seat, shell material. For the use of the valve due to bad sealing or head, seat and other parts of the valve is damaged, you can take the light knife, grinding, surfacing and other methods of repair and use, in order to extend the service life of the valve.

②Gate Valve

It is perpendicular to the direction of media flow by one or two flat plates, with the valve body sealing surface to achieve the purpose of closure. The valve plate is raised to open the valve.

Flat plate with the rotation of the valve stem and lift, with the size of the opening to regulate the flow of fluid. This valve resistance is small, good sealing performance, switching labor-saving, especially suitable for large caliber pipeline, but the gate valve structure is more complex, more types.

According to the stem structure is different, there are open stem and dark stem; according to the structure of the valve plate is divided into wedge type, parallel type and so on.

Generally, the wedge type valve plate is a single valve plate, and the parallel type uses two valve plates. Parallel type is easier to manufacture than wedge type, good repair, use is not easy to deformation, but should not be used for transportation of impurities in the fluid pipeline, more for the transportation of water, clean gas, oil and other pipelines.

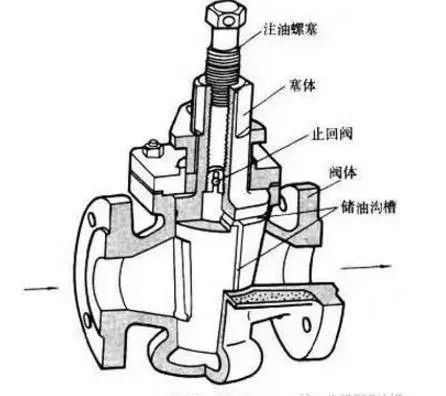

③Plug valves

Plug is commonly known as Cocker, it is the use of the valve body to insert a central hole with a conical plug to open and close the pipeline.

Plug according to the different sealing forms, can be divided into packing plug, oil-sealed plug and no packing plug and so on. The structure of the plug is simple, small external dimensions, open and close quickly, easy to operate, small fluid resistance, easy to make three-way or four-way distribution or switching valve.

Plug sealing surface is large, easy to wear, switching laborious, not easy to adjust the flow, but cut off quickly. Plug can be used for lower pressure and temperature or medium containing solid particles in the fluid pipeline, but should not be used for higher pressure, higher temperature or steam pipeline.

④Throttle Valve

It belongs to one kind of globe valve. The shape of its valve head is conical or streamlined, which can better control the flow of regulated fluids or throttling and pressure regulation. The valve requires high production precision and good sealing performance.

Mainly used for instrumentation control or sampling and other pipelines, but should not be used for viscosity and solid particles in the pipeline.

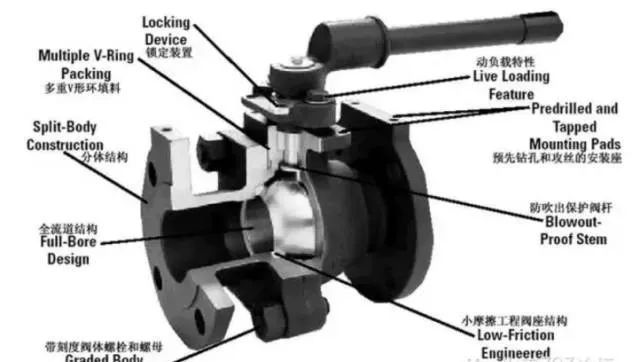

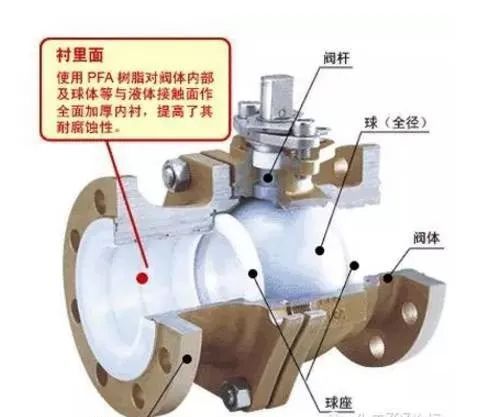

⑤Ball Valve

Ball valve, also known as ball center valve, is a kind of valve developed faster in recent years. It utilizes a ball with a hole in the middle as the valve center, relying on the rotation of the ball to control the valve opening or closing.

It is similar to the plug, but smaller than the sealing surface of the plug, compact structure, switching labor-saving, far more widely used than the plug.

With the improvement of ball valve manufacturing precision, ball valves are not only used in low-pressure pipeline, and has been used in high-pressure pipeline. However, due to the limitations of the sealing material, it is not suitable for use in high temperature pipelines.

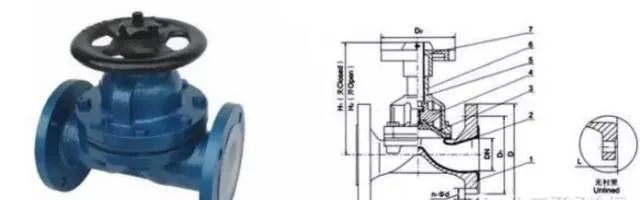

⑥ Diaphragm Valves

Commonly available are rubber diaphragm valves. The opening and closing of this valve is a special rubber diaphragm, the diaphragm is clamped between the valve body and the valve cover, and the disc under the valve stem presses the diaphragm tightly on the valve body to achieve sealing.

This valve has a simple structure, reliable sealing, easy maintenance and low fluid resistance. Suitable for conveying acidic media and fluid pipelines with suspended solids, but generally should not be used for higher pressures or temperatures higher than 60 ℃ pipeline, should not be used for conveying organic solvents and strong oxidizing media in the pipeline.

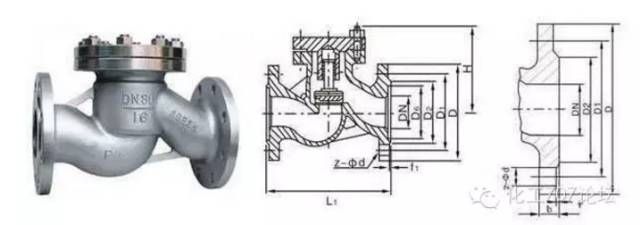

⑦ Check Valve

Also known as non-return valves or check valves. It is installed in the pipeline so that the fluid can only flow in one direction, and the reverse flow is not allowed.

It is a kind of automatic closing valve, there is a valve or rocking plate in the valve body. When the medium flows smoothly, the fluid will automatically open the valve flap; when the fluid flows backwards, the fluid (or spring force) will automatically close the valve flap. According to the different structure of the check valve, is divided into lift and swing type two categories.

Lift check valve flap is perpendicular to the valve channel lifting movement, generally used in horizontal or vertical pipeline; rotary check valve valve flap is often called rocker plate, rocker plate side connected to the shaft, the rocker plate can be rotated around the shaft, rotary check valve is generally installed in the horizontal pipeline, for a small diameter can also be installed in the vertical pipeline, but pay attention to the flow should not be too large.

Check valve is generally applicable to clean media pipeline, containing solid particles and viscosity of the media pipeline should not be used. Lift type check valve closed performance is better than the swing type, but the swing type check valve fluid resistance is smaller than the lift type. In general, the swing check valve is suitable for large caliber pipeline.

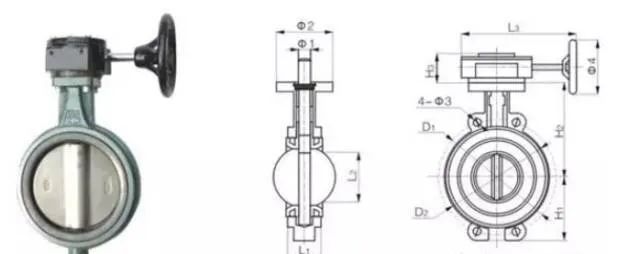

⑧Butterfly Valve

Butterfly valve is a rotatable disk (or oval disk) to control the opening and closing of the pipeline. It is a simple structure, small external dimensions.

Due to the sealing structure and material problems, the valve closed performance is poor, only for low-pressure, large-diameter pipeline regulation, commonly used in the transmission of water, air, gas and other media in the pipeline.

⑨ Pressure Reducing Valve

Is to reduce the medium pressure to a certain value of the automatic valve, the general pressure after the valve to be less than 50% of the pressure before the valve, which mainly rely on the diaphragm, spring, piston and other parts of the medium to control the pressure difference between the valve flap and the valve seat gap to achieve the purpose of pressure reduction.

There are many types of pressure reducing valves, common piston and diaphragm type two.

⑩ lining valve

In order to prevent corrosion of the medium, some valves need to be lined with corrosion-resistant materials (such as lead, rubber, enamel, etc.) in the valve body and valve head, lining materials should be selected according to the nature of the medium.

For the convenience of lining, lined valves are mostly made of right-angle type or direct-flow type.

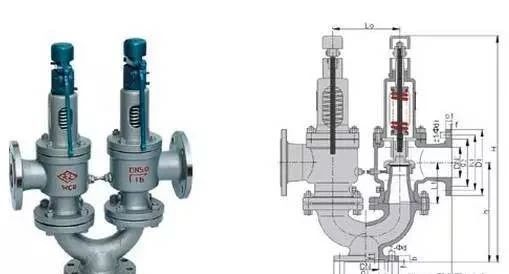

⑪Safety valves

In order to ensure the safety of chemical production, in the pipeline system under pressure, there is a permanent safety device, that is, the selection of a certain thickness of metal sheet, like inserting a blind plate installed in the end of the pipeline or tee interface.

When the pressure in the pipeline rises, the sheet is broken to achieve the purpose of pressure relief. Rupture plates are generally used in low-pressure, large-diameter pipelines, but in most chemical pipelines with safety valves, safety valves are many types, can be broadly divided into two categories, namely, spring-loaded and lever-type.

Spring-loaded safety valves rely mainly on the force of the spring to achieve sealing. When the pressure in the pipe exceeds the spring force, the valve is opened by the medium, and the fluid in the pipe is discharged, so that the pressure is reduced.

Once the pressure in the pipe drops below the spring force, the valve closes again. Lever-type safety valves mainly rely on the force of the weight on the lever to achieve sealing, the principle of action with the spring-type. Safety valve selection, is based on the working pressure and working temperature to determine the nominal pressure level, its caliber size can be calculated with reference to the relevant provisions to determine.

Safety valve structure type, valve material should be selected according to the nature of the medium, working conditions. The starting pressure, test and acceptance of the safety valve have special provisions, regular calibration by the security department, seal printing, in use shall not be arbitrarily adjusted to ensure safety.

Post time: Dec-01-2023