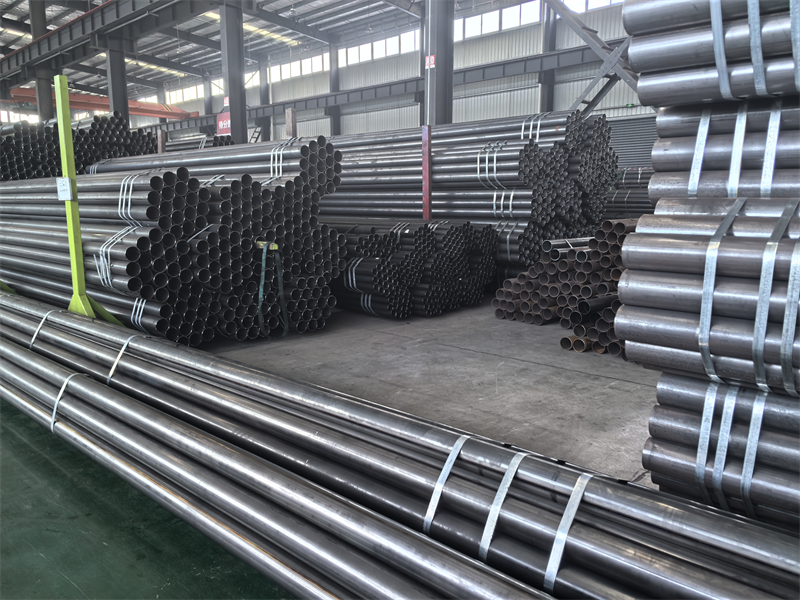

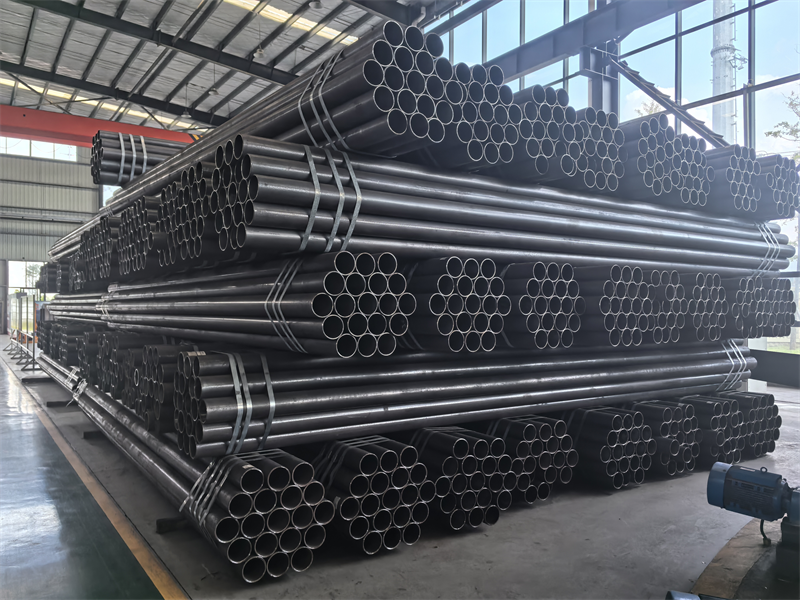

Precision Engineering for High-Performance Applications

Womic Steel is a globally recognized manufacturer of high-quality conveyor roller tubes. These tubes are essential components of conveyor systems, widely used in logistics, mining, metallurgy, ports, food processing, and other industries. Known for their durability, precision, and adaptability, Womic Steel conveyor roller tubes are designed to meet diverse working conditions.

Material Grades and Specifications

Womic Steel ensures the use of premium-grade materials for superior strength, wear resistance, and corrosion protection.

Common Material Grades

- Carbon Steel: Q195, Q235, Q345, S235JR, S355JR

- Stainless Steel: 201, 304, 316L (ideal for corrosive environments)

- Alloy Steel: 16Mn, 20Mn2, 30MnSi (suitable for high-strength applications)

- Galvanized Steel: For enhanced corrosion resistance

Applicable Standards

Our products comply with a range of international and regional standards:

- ASTM: ASTM A513, ASTM A106, ASTM A312

- EN: EN 10210, EN 10219, EN 10305

- JIS: JIS G3445, JIS G3466

- ISO: ISO 10799

- SANS: SANS 657-3 (South African standards for conveyor tubing)

Production Process

Womic Steel employs advanced production techniques and state-of-the-art equipment to deliver precise and reliable conveyor roller tubes.

1. Raw Material Selection

High-quality steel coils are carefully selected and tested for mechanical and chemical properties.

2. Tube Forming

- Cold Rolling: Produces thin-walled tubes with uniform thickness and a smooth surface.

- Hot Rolling: Ideal for thick-walled tubes with superior strength and impact resistance.

- High-Frequency Welded Tubes: Provides strong and seamless welds.

3. Dimensional Precision

Automated CNC equipment ensures the tubes are manufactured to precise lengths, diameters, and wall thicknesses.

4. Heat Treatment

Custom heat treatments (annealing, normalizing, quenching, tempering) enhance toughness and wear resistance.

5. Surface Treatment

- Pickling and Passivation: Removes impurities and enhances corrosion resistance.

- Galvanizing: Adds a zinc layer for long-term rust protection.

- Painting or Coating: Optional for color coding and extra protection.

6. Quality Inspection

All tubes undergo rigorous quality control, including:

- Dimensional Accuracy Testing: Outside Diameter and Ovality Tolerances within ±0.1 mm.

- Mechanical Testing: Tensile strength, yield strength, and elongation tests.

- Non-Destructive Testing (NDT): Ultrasonic and eddy current testing.

- Surface Inspections: Ensures a defect-free finish.

Size Range and Tolerances

Womic Steel offers a wide range of conveyor roller tubes, customizable to suit your needs.

|

Parameter |

Range |

| Outer Diameter (OD) | 20 mm - 300 mm |

| Wall Thickness (WT) | 1.5 mm - 15 mm |

| Length | Up to 12 meters (custom sizes available) |

| Tolerances | Compliant with EN 10219 and ISO 2768 standards |

Key Features

1.Exceptional Durability

Designed to withstand heavy loads and harsh working conditions.

2.Corrosion Resistance

Available in galvanized or stainless steel for humid and chemically aggressive environments.

3.Precision and Stability

Excellent straightness and concentricity reduce vibration and noise in conveyor systems.

4.Low Maintenance

Long-lasting performance minimizes downtime and maintenance costs.

Applications

Womic Steel conveyor roller tubes are widely used in:

- Logistics and Warehousing: Sorting systems, roller conveyors.

- Mining and Metallurgy: Bulk material handling systems.

- Food Processing: Hygienic stainless steel tubes for clean environments.

- Ports and Terminals: Cargo handling conveyor systems.

- Chemical and Pharmaceutical: Corrosion-resistant rollers for chemical handling.

Custom Solutions

We provide fully customizable options to suit unique project requirements:

- Non-Standard Sizes: Tailored dimensions for specific equipment.

- Surface Treatments: Galvanizing, painting, or passivation available.

- Packaging Options: Custom packaging to ensure safe transport.

Conclusion

Womic Steel conveyor roller tubes are engineered to meet the highest industry standards and deliver exceptional performance. With advanced manufacturing capabilities, stringent quality control, and customization options, our products are a reliable choice for diverse industries worldwide.

For more information or a custom quote, contact Womic Steel today!

Email: sales@womicsteel.com

MP/WhatsApp/WeChat:Victor:+86-15575100681 Jack: +86-18390957568

Post time: Jan-08-2025