Product Overview

Womic Steel is a leading manufacturer of high-quality EN10216-certified seamless steel tubes, specializing in precision engineering and global delivery. Our seamless tubes are designed and produced to meet the most stringent industry standards, offering excellent durability, reliability, and performance in a wide range of applications, including mechanical engineering, hydraulic cylinders, automotive systems, and more.

Production Range

Womic Steel produces seamless steel tubes in a wide range of sizes and specifications, including:

●Diameter (OD): 1/4" (6.35 mm) to 36" (914.4 mm)

●Wall Thickness: 0.5 mm to 40 mm (depending on the tube diameter)

●Length: Custom lengths up to 12 meters (standard) or per customer requirements.

Our seamless steel tubes are manufactured from high-quality materials that comply with international standards and are engineered for a variety of applications such as fluid transport, pressure vessels, mechanical structures, and precision components.

Material Grades

Womic Steel offers a range of material grades for seamless tubes, ensuring compatibility with various industries and applications. Our available grades include:

●P235TR1 (EN10216-2)

●P235TR2 (EN10216-2)

●P265GH (EN10216-2)

●1.4301 (AISI 304) (EN10216-5 for stainless steel)

●1.4401 (AISI 316) (EN10216-5 for stainless steel)

●S355J2H (EN10210-1 for structural tubes)

●11CrMo9-10, 13CrMo44, T22 (for high-temperature applications)

Each material grade is tested and certified according to relevant industry standards, including EN10216, ISO 9001, and other applicable certifications.

Dimensional Tolerances

Womic Steel ensures precision in the manufacturing of seamless steel tubes. Our tubes meet the following dimensional tolerances:

|

Parameter |

Tolerance |

| Outside Diameter (OD) | ±0.3% (up to 120mm) |

| Wall Thickness (WT) | ±10% (0.5-6mm) |

| Ovality (Ovality of OD) | ≤ 1% of OD |

| Length | ±10 mm |

| Straightness | 1.5 mm/m |

| End Squareness | ≤ 1.0 mm |

Manufacturing Process

The seamless steel tubes produced by Womic Steel undergo a rigorous and highly controlled manufacturing process, ensuring high-quality standards and performance. The process includes the following stages:

Billet Selection & Inspection:

The production begins with high-quality billets, which are thoroughly inspected for material integrity and suitability for further processing.

Piercing & Extrusion:

The billets are heated to the desired temperature, then pierced and extruded to form a hollow tube.

Cold Drawing (Cold-Forming):

The tubes are cold drawn through a die to achieve precise dimensions. This process also improves the mechanical properties of the steel.

Heat Treatment:

The tubes are subjected to heat treatment processes such as normalizing or annealing to relieve stresses and improve strength and ductility.

Pickling:

The tubes are pickled to remove surface impurities and oxides, ensuring a clean and smooth finish.

Straightening & Cutting:

After heat treatment, the tubes are straightened, cut to the desired length, and subjected to dimensional checks.

Surface Treatment:

Tubes undergo additional surface treatments, such as polishing or coating, as required by the application.

Final Inspection & Testing:

All tubes undergo comprehensive quality control checks, including dimensional verification, visual inspection, and mechanical testing.

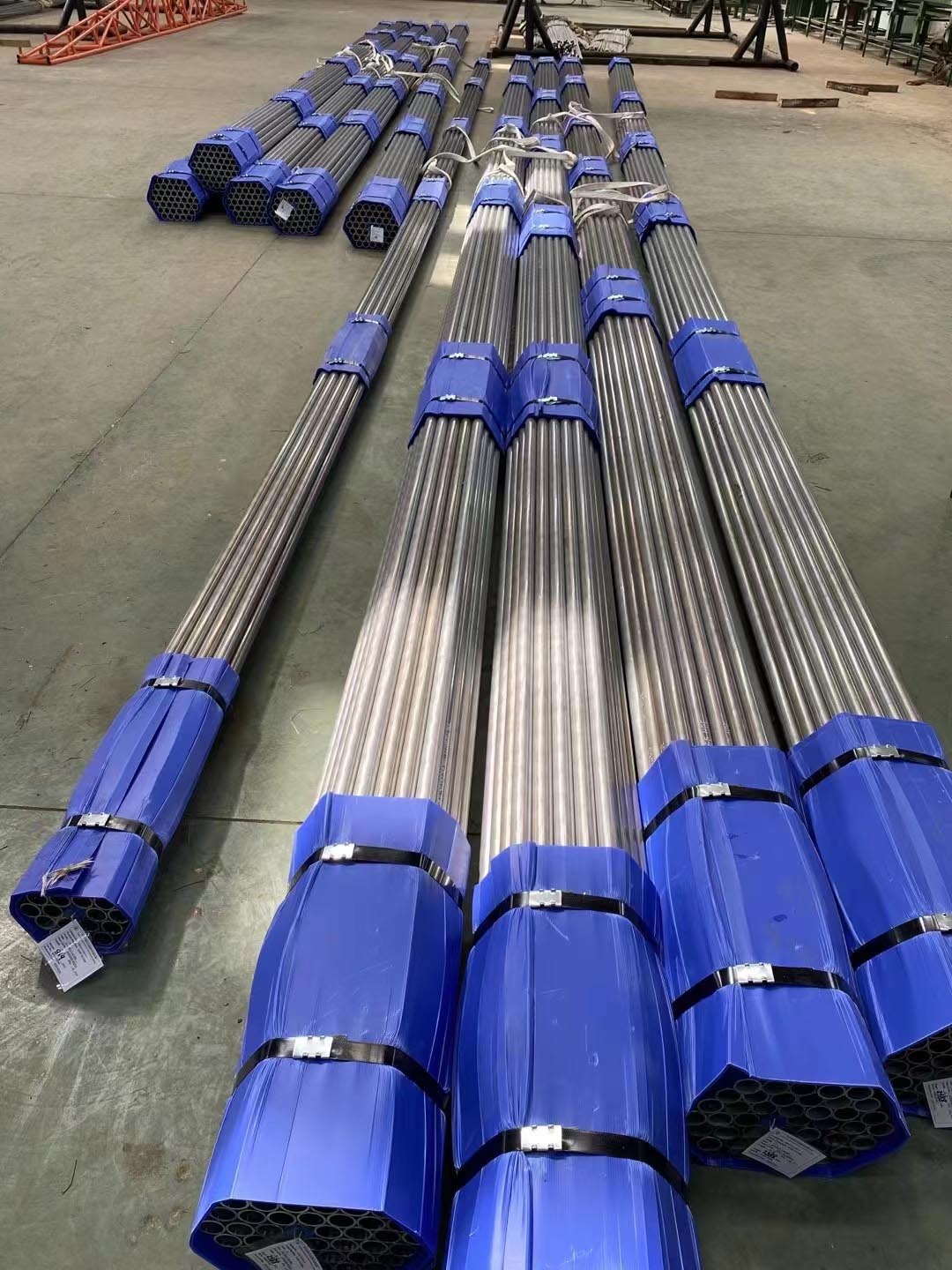

Packaging

At Womic Steel, we prioritize the safe and secure transportation of our products. The seamless steel tubes are carefully packaged to prevent damage during transit. Our packaging methods include:

●Protection: Tubes are coated with a protective layer to prevent rust and corrosion.

●End Caps: Both ends of the tubes are fitted with protective caps to avoid dirt and moisture entry.

●Bundling: Tubes are bundled and strapped with steel or plastic bands to hold them securely.

●Shrink Wrapping: Bundled tubes are wrapped in shrink film for additional protection against dust and environmental factors.

●Labeling: Each package is clearly labeled with product information, including size, material grade, batch number, and quantity.

Transportation

●Global Shipping: We offer global delivery of seamless steel tubes, ensuring prompt and reliable transportation to any destination.

●Sea Freight & Road Transport: Tubes are shipped using sea freight (for international shipments) or road transport (for domestic and regional deliveries), with secure packaging and tracking to ensure safe arrival.

●Flat-Rack Shipping: For longer tubes, we use flat-rack shipping to prevent bending or deformation during transit.

Technical Requirements & Testing

Womic Steel's seamless steel tubes undergo the following inspections and tests to ensure they meet the highest quality standards:

1.Dimensional Inspection: Ensuring the precise dimensions of the tubes according to customer requirements.

2.Mechanical Testing: Includes tensile strength, yield strength, elongation, and hardness tests, all performed in our accredited laboratories.

3.Ultrasonic Testing: To detect any internal defects or inconsistencies.

4.Eddy Current Testing: Used for detecting surface cracks or other anomalies.

5.Hydrostatic Testing: Tubes are tested for pressure tolerance to ensure they meet safety and performance standards.

6.Visual Inspection: Every tube is thoroughly inspected for surface defects and any visible imperfections.

7.Chemical Composition Testing: To verify that the material meets the required chemical specifications.

Our in-house laboratories are equipped with state-of-the-art testing equipment to conduct all necessary tests in compliance with EN10216 and ISO 9001 standards. We also provide certified test reports for each order upon request.

Advantages of Womic Steel

●Precision Engineering: We specialize in high-precision seamless steel tubes that meet the most stringent quality standards.

●Custom Solutions: Womic Steel offers flexibility in terms of sizes, material grades, and coatings to meet the specific needs of our customers.

●Global Delivery: With a robust logistics network, we ensure timely delivery to any location worldwide.

●Quality Assurance: Our comprehensive testing and quality control procedures guarantee that every product we ship meets the highest standards.

●Customer-Focused Service: We prioritize customer satisfaction with tailored solutions and responsive service.

Womic Steel is your trusted partner for EN10216-certified seamless steel tubes, offering high-quality products, precision engineering, and reliable global delivery.

For more details, please contact us directly.

Choose Womic Steel Group as your reliable partner for high-quality Stainless Steel Pipes&Fittings and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Feb-13-2025