Womic Steel produced Precision Seamless cold-drawn steel pipes/tubes.

“Precision” is the company Womic Steel’s operating characteristics. Among them: small-caliber seamless steel pipe outer diameter can be achieved wall thickness can be 0.5mm-14mm. Annual stock 6*1mm, 8 *1mm, 10*1mm, 3mm-50mm, small caliber seamless steel pipe, can be annealed without oxygen. Customization time is fast. “Precision” is highly precision, the inner diameter tolerance can be 5 wires, concentricity 0.1, finish 0.4 or more, and linearity 0.1. “Special” is a special material. All kinds of alloy steel: 30 crmn5, 20 CRMN, 16 mn, 15 crmo, 20 crmo, 30 crmo, 42 crmo, 37 mn5, mn2 20, 20 mn, mn2 40, 65 m, 17-4, 10 Cr17, 1 cr13, 2 cr13 and 3 cr13, 1 Cr17, Such as 1Cr17Ni2. All kinds of seamless steel pipes can be annealed without oxygen, casing annealing, polishing treatment and other technical requirements. In addition can also be customized according to customer requirements of all kinds of square pipe, oval pipe, hexagonal pipe, outer circle inner oval pipe, outer flat inner circle and other steel pipes.

Cold drawn precision steel tube is a high-precision steel tube manufactured by cold drawing process, which has superior dimensional accuracy and surface quality. Here are some key features and application areas of cold drawn precision steel tube:

Manufacturing process: The manufacturing process of cold drawn precision steel tube is carried out at room temperature, by cold drawing solid round steel rods or hollow tubes for multiple times to achieve the required dimensional accuracy and surface finish.

Dimensional accuracy: Due to the stretching and extrusion during the cold drawing process, the dimensional control of cold drawn precision steel tube is very strict, and can achieve very high precision requirements, usually within a few microns.

Surface quality: The surface finish of cold drawn precision steel tube is very high, usually does not require subsequent surface treatment, and can be directly used in high-demand application areas.

Material selection: Commonly used materials include carbon steel, alloy steel, stainless steel, etc. Cold drawn precision steel tubes of different materials can be selected according to the specific use environment and requirements.

Application areas: Cold drawn precision steel tubes are widely used in automobile manufacturing, aerospace, machinery manufacturing, electronic equipment, petrochemical and other industries. In these fields, cold-drawn precision steel tubes are usually used to manufacture high-precision and high-demand components and equipment such as bearings, automobile transmission shafts, hydraulic cylinders, and precision instruments.

Usage of the precision steel tubes:

Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special Purpose

Advantages: Compared with hot-rolled or hot-extruded steel tubes, cold-drawn precision steel tubes have the advantages of good dimensional stability, high internal and external surface finish, and excellent mechanical properties, which can improve the wear resistance, corrosion resistance and service life of the product.

In short, cold-drawn precision steel tubes play an important role in modern manufacturing with their high precision, excellent surface quality and wide application fields, providing reliable solutions and efficient material selection for various engineering projects.

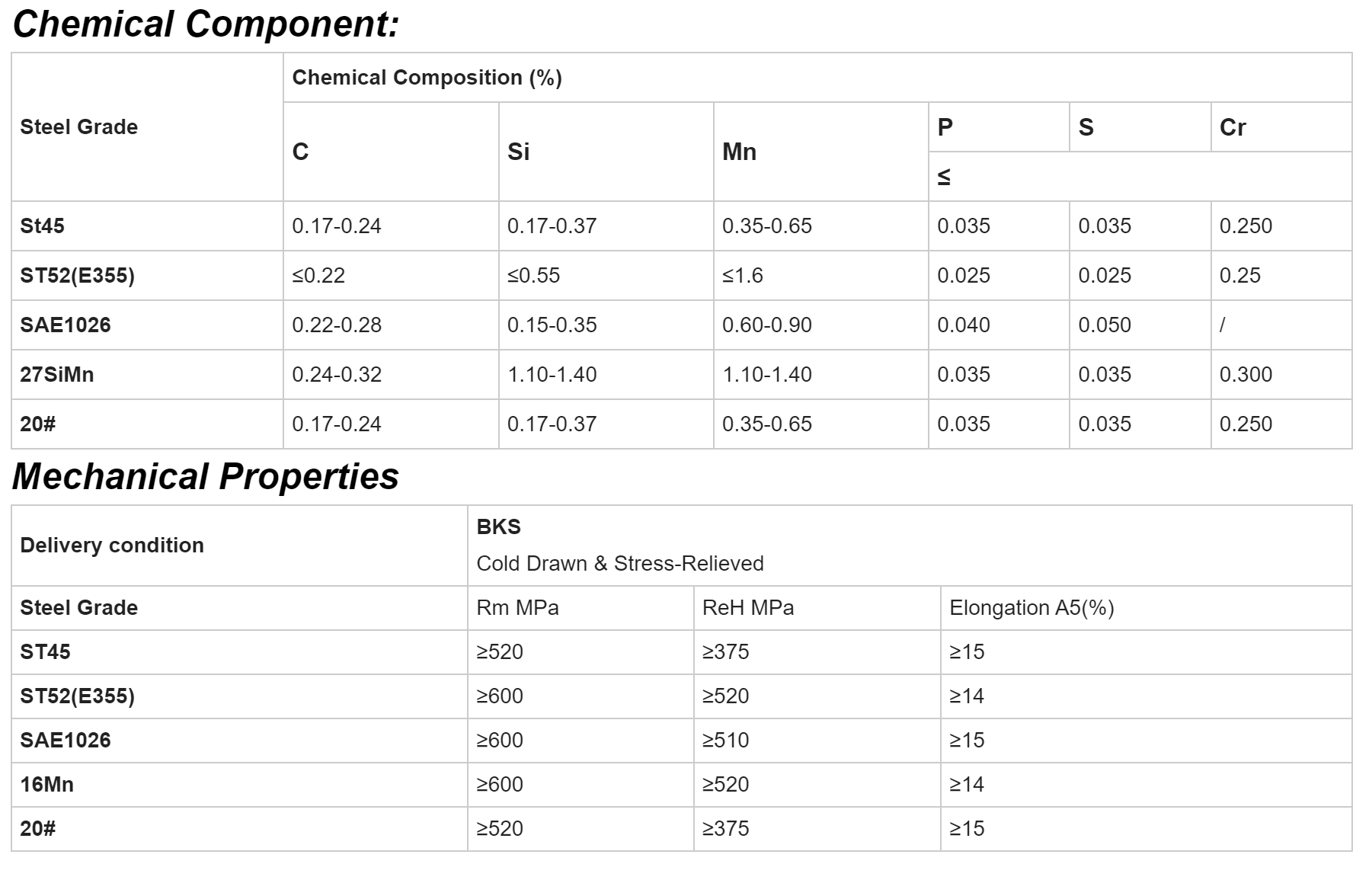

Standards / Material of the precision steel tubes:

En 10305-1, DIN2391, En10305, JIS G3445, ASTM A519, GB/T 8713, ST45, ST52, E355, E355SR, STKM13C, SAE1026, 20#, Q235B, CK45…

En 10305-1 E215 E235 E355 Honed Seamless Hydralic Cylinder Steel Pipe

EN10305-1 E235 European standard small diameter precision cold-drawn hydraulic seamless pipe

EN 10305-1-2016 Technical conditions for the delivery of steel pipes for precision instruments Seamless cold-drawn steel pipes

The other Implementation standards of steel tubes/pipes produced by Womic Steel:

GB3087-2008 Seamless steel pipes for low and medium pressure boilers

GB/T3091-2008 Welded steel pipes for low pressure fluid transportation

GB/T3639-2000 Cold drawn or cold rolled precision seamless steel pipes

GB5310-2008 Seamless steel pipes for high pressure boilers

GB/T8162-2008 Seamless steel pipes for general structures

GB/T8163-2008 Seamless steel pipes for conveying fluids

GB5310-2008 Seamless steel pipes for high pressure boilers

GB/T5312-2009 Carbon steel pipes and carbon manganese steel seamless steel pipes for ships

GB6479-2000 Seamless steel pipes for high pressure fertilizer equipment

GB/T9711.1-1997 Steel pipes for oil and gas industry Part 1: Grade A steel pipes

GB/T9808-2008 Seamless steel pipes for drilling

GB9948-2006 Seamless steel pipes for petroleum cracking

GB/T17396-2009 Hot-rolled seamless steel pipes for hydraulic props

GB/T18984-2003 Seamless steel pipes for low-temperature pipelines

GB/T19830-2005 Steel pipes for oil and gas well casing or oil pipes in the oil and gas industry

GB/T20409-2006 Seamless steel pipes with internal threads for high-pressure boilers

GB/T20801-2006 Pressure piping specifications Industrial pipelines

GB 24512.1-2009 Seamless steel pipes for nuclear power plants Part 1 Carbon steel seamless steel pipes

GB 24512.2-2009 Seamless steel pipes for nuclear power plants Part II Alloy Steel Seamless Pipe

GB/T 24591-2009 Seamless Steel Pipe for High-Pressure Feedwater Heater

GJB 2608-96 Thick Wall Seamless Steel Pipe for Aviation Structural Steel

YB/T4146-2006 (YB/Z12-1977, GB/T18254-2002) Bearing Steel Seamless Pipe

09CrCuSb(ND) Steel Pipe for Sulfuric Acid Dew Point Corrosion Resistance (GB150-1998)

CB*3075-87 Marine Seamless Steel Pipe

API Spec 5CT-2005 Casing and Oil Pipe Specification

API Spec 5L-2007 Line Pipe Specification

ASTM A53/ASME SA53 Black and Hot-Dip Galvanized Welded and Seamless Steel Pipe

ASTM A106/ ASME SA106 Seamless Carbon Steel Pipe for High Temperature

ASTM A179/ASME SA179 Seamless cold drawn low carbon steel pipe for heat exchangers and condensers

ASTM A192/ASME SA192 Seamless carbon steel boiler tube for high pressure equipment

ASTMA199/ASME SA199 Cold drawn seamless alloy steel pipe for heat exchangers and condensers

ASTMA200/ASME SA200 Seamless medium alloy steel furnace tube for refineries

ASTM A210/ASME SA210 Seamless medium carbon steel pipe for boilers and superheaters

ASTM A213/ASME SA213 Seamless ferritic and austenitic alloy steel pipe for boilers, superheaters and heat exchangers

ASTM A333/ASME SA333 Seamless and welded steel pipe for low temperature equipment

ASTM A334/ASME SA334 Seamless and welded carbon steel and alloy steel pipe for low temperature

ASTM A335/ASME SA335 Seamless ferritic alloy steel pipe for high temperature

ASTMA500/ASME SA500 round and special-shaped cold-formed welded and seamless carbon steel structural pipes

ASTM A519/ASME SA519 seamless carbon steel pipes and alloy steel pipes for machinery

ASTM A556/ASME SA556M seamless cold-drawn carbon steel pipes for water heaters

BS 3059 seamless steel pipes for boilers and superheaters

BS 3601-1987 Carbon steel pipes with specified room temperature properties for pressure

BS 3602-1 Pressure steel pipes. Carbon steel and carbon manganese steel pipes with specified high temperature properties.

BS 6323-4 Specification for seamless and welded steel pipes for automobile manufacturing, machinery manufacturing and general engineering. Part 4: Cold-rolled seamless steel pipes

BS EN 10208-1-1998 Flammable liquid pipeline steel pipes. Technical submission conditions. Grade A requirement pipes.

EN 10210-1-2006 Hot finished structural hollow sections of non-alloy and fine grain structural steels Part 1

EN 10216-1 Seamless steel tubes for pressure purposes Part 1: Non-alloy steel tubes with specified room temperature properties

EN 10216-2 Seamless steel tubes for pressure purposes Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10255-2004 Non-alloy steel tubes suitable for welding and threading

EN 10297-1 Seamless circular steel tubes for mechanical and general engineering purposes

EN 10305-1 Technical delivery conditions for precision seamless steel tubes Part 1: Seamless cold drawn steel tubes

DIN 1629 Non-alloy steel circular seamless tubes of special quality requirements

DIN 1630 High performance circular carbon steel seamless tubes

DIN 2391 Cold drawn or cold rolled precision seamless steel tubes

DIN 2448 Seamless steel tubes. General table of dimensions and weights per unit length

DIN 17172-1991 Technical conditions for delivery of steel pipes for conveying flammable liquids and gases

DIN 17175 Seamless steel pipes made of heat-resistant steel

DIN 17204 Seamless round steel pipes

JIS G3441 Alloy steel pipes for mechanical structures

JIS G3444-2004 Carbon steel pipes for general structures

JIS G3445 Carbon steel pipes for ordinary structures

JIS G3452 (SGP) Carbon steel pipes for general pipelines

JIS G3454 Carbon steel pipes for pressure pipelines

JIS G3455-2005 Carbon steel pipes for high-pressure piping

JIS G3456-2004 Carbon steel pipes for high-temperature piping

JIS G3458 Alloy steel pipes for piping

JIS G3460-2006 Steel pipes for low-temperature pipelines

JIS G3461 Steel pipes for boilers and heat exchangers

JIS G3462 Alloy steel pipes for boilers and heat exchangers

JIS G3464-2006 Steel pipes for heat exchangers for low-temperature equipment

JIS G3467-2006 Steel pipes for heating furnaces

JIS G3473-2007 Carbon steel pipes for cylinder barrels

JIS G3475-2008 Carbon steel pipes for building structures

JIS G4051 Carbon steel for mechanical structures

JISG4053-2003 Low alloy steel for machine structures

JIS G7215-2003 Seamless steel pipes for machinery with smooth ends (ISO specification)

JIS G7219-2003 Seamless steel pipes for pressure. Part 1: Non-alloy steel with specified room temperature properties (ISO specification)

JIS G7220-2003 Seamless steel pipes for pressure. Part 2: Non-alloy steel and alloy steel with specified high temperature properties (ISO specification)

JIS G7221-2003 Seamless steel pipes for pressure. Part 3: Non-alloy steel and alloy steel with specified low temperature properties (ISO specification)

NF A 49-211 Non-alloy steel smooth end seamless pipes for high temperature fluid transmission pipelines

NF A 49-213 Non-alloy steel and molybdenum and chromium-molybdenum alloy steel seamless steel pipes for high temperature

NF A 49-215-1981 Non-alloy steel and ferritic alloy steel seamless steel pipes for heat exchangers

GOST 550-75 Seamless steel pipes for petroleum processing and petrochemical industry

ISO 2937-1974 Seamless steel pipes for machinery with smooth ends

ISO 11960:2001 Steel pipes for oil well casing and tubing in petroleum and natural gas industries

ISO 3183:2007 Petroleum and natural gas industries: Steel pipes for pipeline transportation systems

ISO 9329-1:1989 Seamless steel tubes for pressure purposes Part 1: Non-alloy steels with specified room temperature properties

ISO 9329-2:1997 Seamless steel tubes for pressure purposes Part 2: Non-alloy steels and alloy steels with specified elevated temperature properties

ISO 9329-3:1997 Seamless steel tubes for pressure purposes Part 3: Non-alloy steels and alloy steels with specified low temperature properties

Post time: Jun-27-2024