Product Description

Precision steel pipe is the kind of carbon steel , alloy steel or stainless steel pipes with high precision sizes. Usually produced in hot rolling or cold drawn (cold rolling) processes. So precision pipe are seamless pipes, some precision pipes are welded steel pipes.

Precision pipes designed with several advantages:

● Inside and outside surface no any coating;

● Precision tubes could bear high pressure, no leaking;

● Strict less tolerance;

● Surface smoothly

● No reformation in cold bending, no cracks during flaring test and flattening test.

Precision pipes tubes widely used for manufacturing the pneumatic parts and hydraulic components

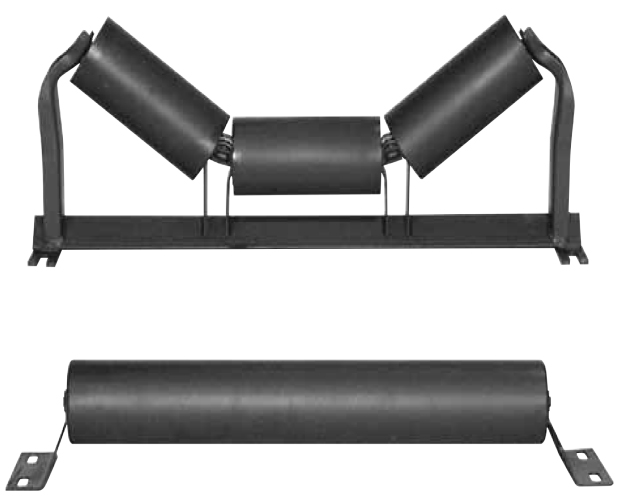

The internal and external diameter could control within +/- 0.01 mm. In the guarantee of anti-bending strength and torque strength same, the weight of precision pipe is lighter. It can be widely used in manufacturing precision machinery parts and engineering structure, and also commonly used to produce various kinds of conventional weapons, barrel, shells, bearing, conveyor rollers, sugar mills ect.

The highly precise steel pipes & tubes we produced widely used for idler roller manufacturer for many years.

It's really excited to learn that your company also do well in Idler Roller manufacturer, since we also have many other customers doing the same business as yours.

The precise steel pipes produced by us range and tolerance control as below :

Regular production diameter: 101.6mm, 108mm, 127mm, 133.1mm, 152.4mm, 158.8mm, 165.1mm, 177.8mm, 219.1mm etc, also customized sizes available.

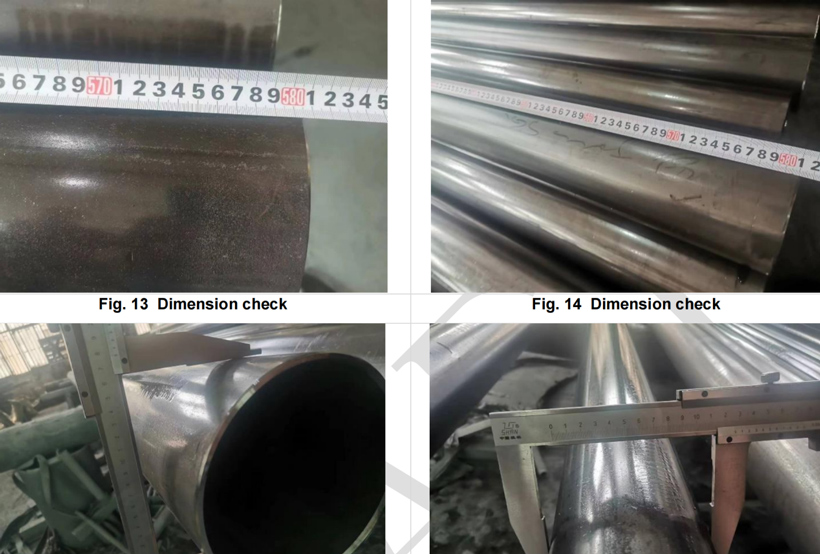

Tolerance control :

OD 101.6mm ~ 127mm, On Specified OD Tolerance ±0.1 mm, Ovality 0.2 mm;

OD 133.1mm ~ 219.1mm, On Specified OD Tolerance ±0.15mm, Ovality 0.3 mm;

On wall Thickness :

±0.1 mm for the pipe wall thickness below and include 4.5mm,

±0.1 mm for the pipe wall thickness above 4.5mm.

Straightness :

Shall not exceed 1 in 1000 (measured at the midpoint of the tube).

Production time is normally 20 days, Looking forward your warm reply and inquiries, thank you

Specifications

| Womic Steel Precision Steel Pipes Prodution Specification Sheet | |||||||||

| ROUND TUBE FOR CONVEYOR IDLERS AND ROLLS | Tube OD [mm] |

Tube ID [mm] |

Wall Th [mm] |

Weight kg/m |

SANS 657-3 | OD Tolerance | WT Tolerance | Length Tolerance | Ovality Max. |

| 101.60 | 94.60 | 3.5 | 8.46 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 114.00 | 107.00 | 3.5 | 9.53 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 133.10 | 126.10 | 3.5 | 11.18 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 133.10 | 125.10 | 4.0 | 12.73 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 119.4 | 3.8 | 11.54 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 118.00 | 4.5 | 13.59 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 117.00 | 5.0 | 15.04 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 115.00 | 6.0 | 17.90 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 120.00 | 3.5 | 10.65 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 144.40 | 4.0 | 14.63 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 143.40 | 4.5 | 16.41 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 142.40 | 5.0 | 18.17 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 144.40 | 4.0 | 14.63 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 140.40 | 6.0 | 21.65 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 158.80 | 149.80 | 4.5 | 17.12 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 159.00 | 151.00 | 4.0 | 15.28 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 159.00 | 150.00 | 4.5 | 17.14 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 177.80 | 165.80 | 6.0 | 25.41 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 193.70 | 181.70 | 6.0 | 27.76 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 157.00 | 4.0 | 15.87 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 153.00 | 6.0 | 4.04 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 156.00 | 4.5 | 17.80 | Part 3 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 97.60 | 2.0 | 4.91 | -- | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 96.00 | 2.8 | 6.82 | -- | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 123.00 | 2.0 | 6.16 | -- | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 146.80 | 2.8 | 10.32 | -- | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| ROUND TUBE STRUCTURAL MATERIAL | Tube OD [mm] |

Tube ID [mm] |

Wall Th [mm] |

Weight kg/m |

SANS 657-3 | OD Tolerance | WT Tolerance | Ovality Max. |

|

| 31.80 | 25.80 | 3.0 | 2.13 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 48.40 | 42.40 | 3.0 | 3.36 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 63.50 | 57.50 | 3.0 | 4.47 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 76.20 | 69.20 | 3.5 | 6.27 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 76.20 | 67.20 | 4.5 | 7.95 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 84.90 | 2.0 | 4.28 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 82.90 | 3.0 | 6.35 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 81.90 | 3.5 | 7.37 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 78.90 | 5.0 | 10.34 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 95.60 | 3.0 | 7.29 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 92.60 | 4.5 | 10.77 | Part 1 | ±0.1 mm | ±0.1 mm | ± 20mm | 0.2 mm | |

| Straightness Shall not exceed 1mm in 1200mm length (measured at the midpoint of the tube). | |||||||||

| CLEAN, FREE OF MILL SCALE AND RUST OR ANY OTHER SUBSTANCES, SUCH AS OIL, GREASE Etc.. | |||||||||

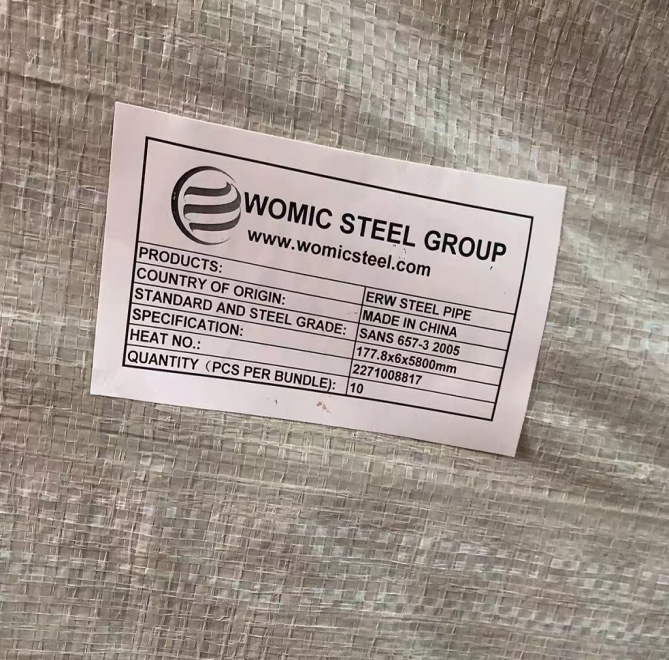

Standard & Grade

SANS 657-3, Precision tubes for conveyor roller manufacturing.

EN 10305-1, Precision tubes for Heat exchanger and condenser.

DIN 2393, Welded precision steel tubes Hydraulic system steel tube

BS6323/4, Precision pipes for Electric industry,

NF A 49-310, NF A 49-312, Precision pipes for Construction machinery

UNI 7945, Seamless precision steel tubes. Steel grade. Fe 280

STN/ČSN 42 6711, Precision seamless steel tubes

STN/ČSN 42 6712, Precision seamless steel tubes

PN-H 74240, PN-H 74220 Russian Standard Precision Pipes

ASTM A450 a A519, Ferritic Alloy / Austentic Alloy Precision Steel Tubes

GOST 8734, 9567, 12132 Seamless cold-formed precision steel tubes

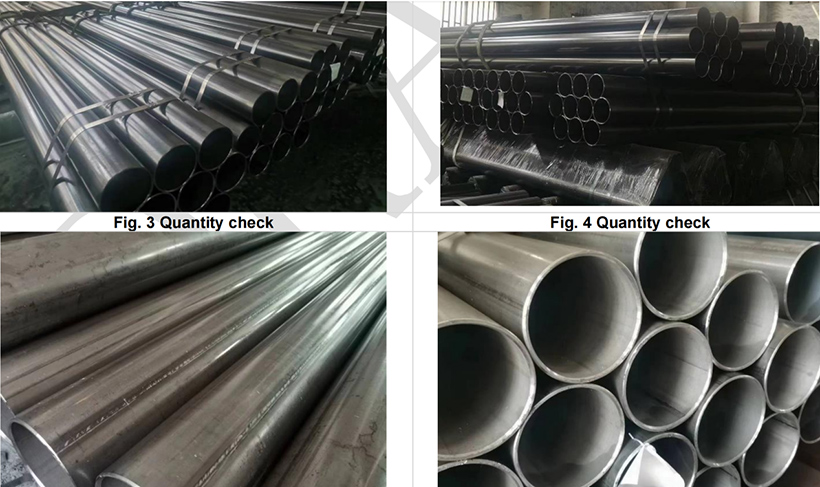

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection , Tension Test, Dimension Check, Bend Test , Flattening Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test…..

Marking, Painting before delivery.

Packing & Shipping

The packaging method for steel pipes involves cleaning, grouping, wrapping, bundling, securing, labeling, palletizing (if necessary), containerization, stowing, sealing, transportation, and unpacking. Different kinds of steel pipes and fittings with different packing methods. This comprehensive process ensures that the steel pipes shipping and arrive at their destination in optimal condition, ready for their intended use.

Usage & Application

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide.

The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...