Product Description

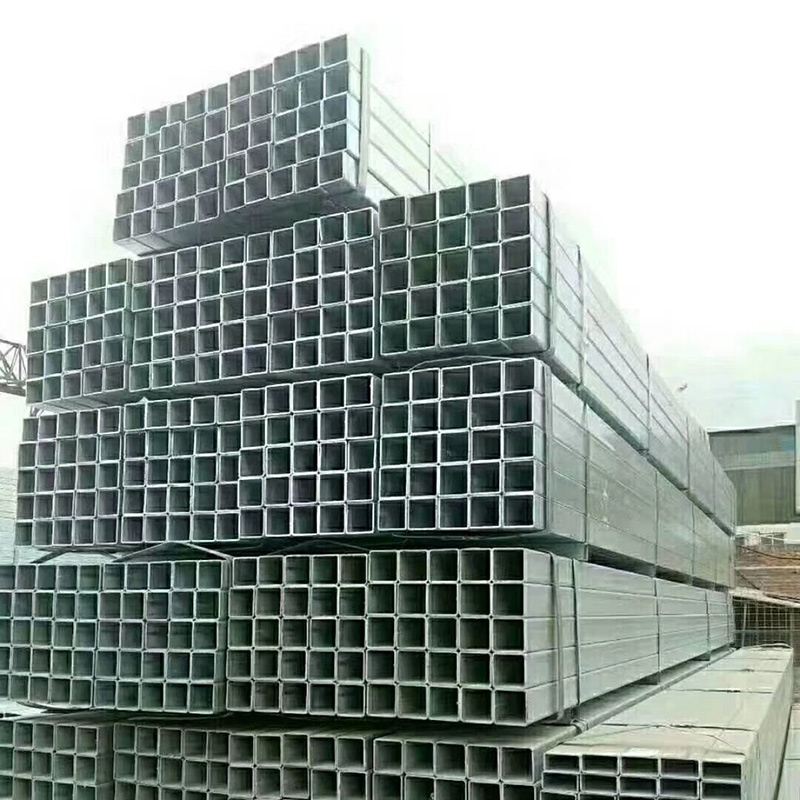

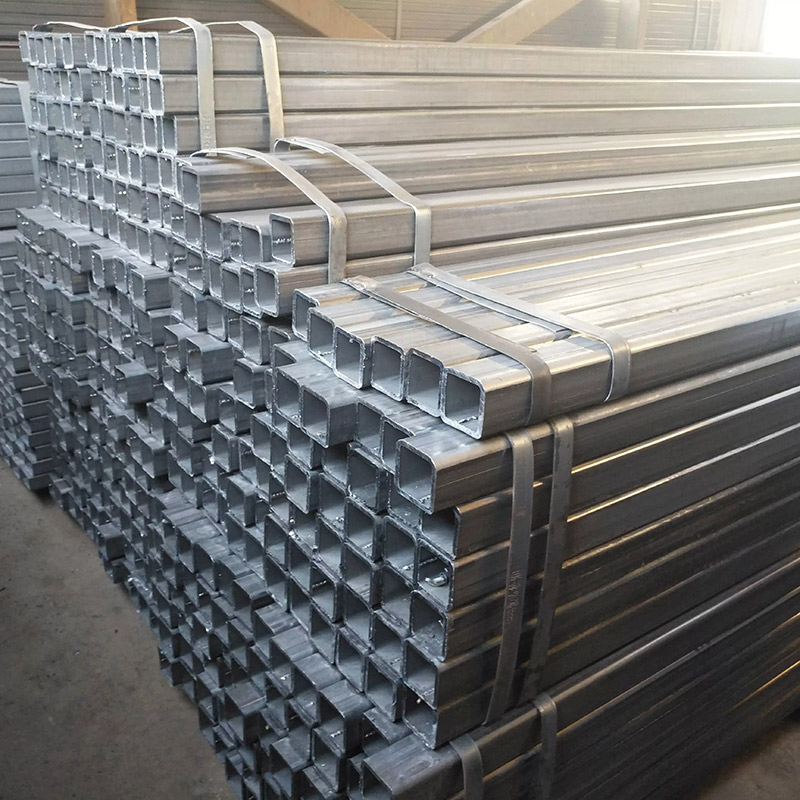

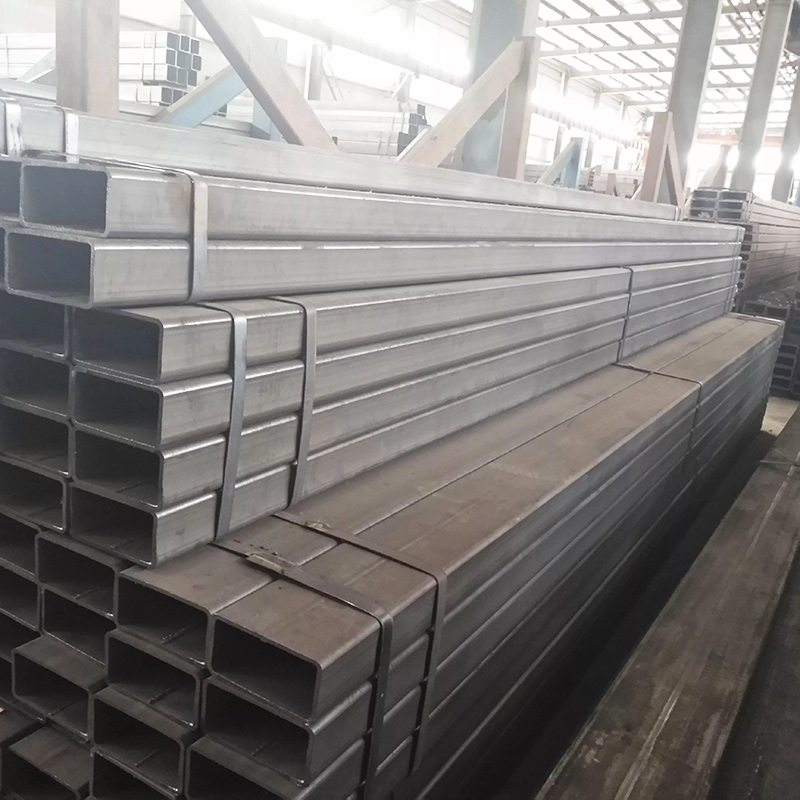

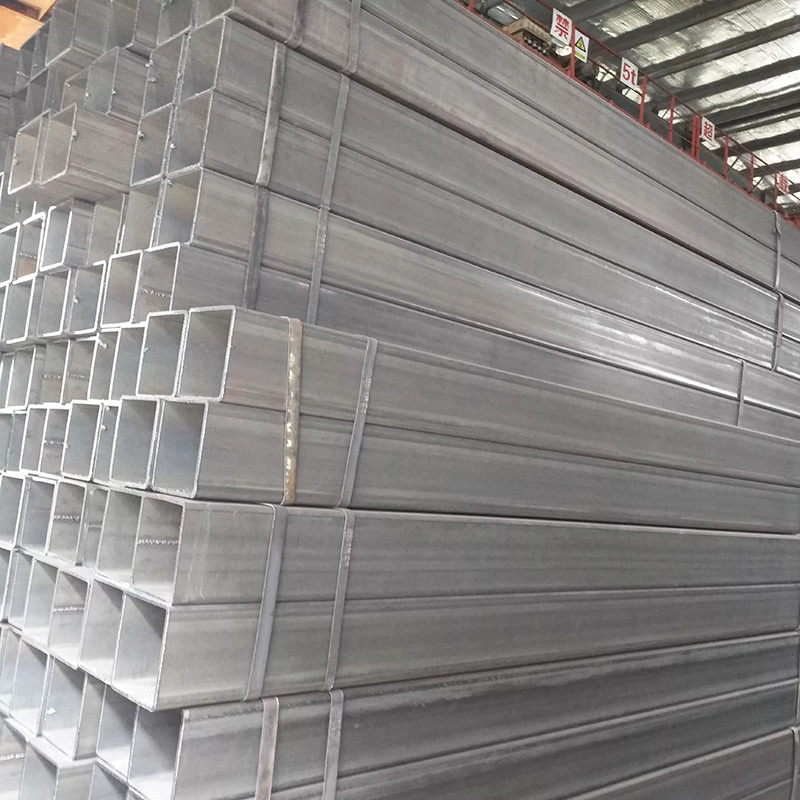

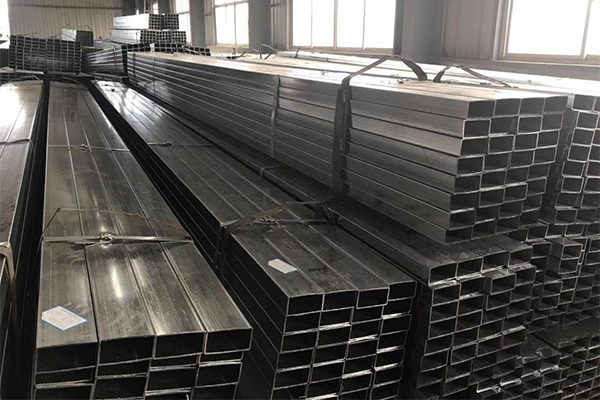

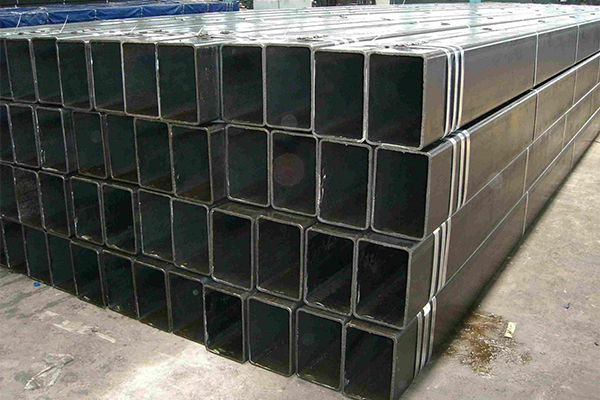

Square & rectangular pipes tube is an extruded pipes that is widely used for all types of fabrication projects where lightweight and corrosion resistance is a primary concern. Square tube has square corners inside and outside, with no weld seam.

Square & rectangular pipes tube are versatile, durable, and cost-effective building materials used in construction, industrial, furniture, and decorative applications. Womic Steel offers a wide range of steel square tubes in various sizes and thicknesses.

Rectangular/ Square hollow section are formed from the coils and then ran through a series of dies. They are are welded from the inside to form their shape.

Process of hollow section (Square/Rectangular tubes):

● Cold Formed Square Hollow Section

● Cold Formed Rectangular Hollow Section

● Hot Finish Square Hollow Section

● Hot Finish Rectangular Hollow Section

Production Process Classification of Square Steel Pipe

According to the production process, square pipe is divided into: hot rolled seamless square pipe, cold drawn seamless square pipe, extruded square pipe without dimension, welded square pipe.

The welded square / rectangular pipe is divided into:

(a) according to the process of an arc welded square pipe, resistance welded square pipe (high frequency, low frequency), gas welded square pipe, furnace welded square pipe.

(b) according to the weld of straight welded square pipe, spiral welded square pipe.

Specifications

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| BS 1387: Class A, Class B |

| ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Grade C250 , Grade C350, Grade C450 |

| SANS 657-3: 2015 |

|

Square steel pipes/tubes production sizes: Out diameter: 16*16mm ~ 1000*1000mm Wall thickness: 0.4mm ~ 50mm |

|

| Sizes by MM (diameter) | Thickness |

| mm | mm |

| 16mm×16mm | 0.4mm~1.5mm |

| 18mm×18mm | 0.4mm~1.5mm |

| 20mm×20mm | 0.4mm~3mm |

| 22mm×22mm | 0.4mm~3mm |

| 25mm×25mm | 0.6mm~3mm |

| 30mm×30mm | 0.6mm~4mm |

| 32mm×32mm | 0.6mm~4mm |

| 34mm×34mm | 1mm~2mm |

| 35mm×35mm | 1mm~4mm |

| 38mm×38mm | 1mm~4mm |

| 40mm×40mm | 1mm~4.5mm |

| 44mm×44mm | 1mm~4.5mm |

| 45mm×45mm | 1mm~5mm |

| 50mm×50mm | 1mm~5mm |

| 52mm×52mm | 1mm~5mm |

| 60mm×60mm | 1mm~5mm |

| 70mm×70mm | 2mm~6mm |

| 75mm×75mm | 2mm~6mm |

| 76mm×76mm | 2mm~6mm |

| 80mm×80mm | 2mm~8mm |

| 85mm×85mm | 2mm~8mm |

| 90mm×90mm | 2mm~8mm |

| 95mm×95mm | 2mm~8mm |

| 100mm×100mm | 2mm~8mm |

| 120mm×120mm | 4mm~8mm |

| 125mm×125mm | 4mm~8mm |

| 130mm×130mm | 4mm~8mm |

| 140mm×140mm | 6mm~10mm |

| 150mm×150mm | 6mm~10mm |

| 160mm×160mm | 6mm~10mm |

| 180mm×180mm | 6mm~12mm |

| 200mm×200mm | 6mm~30mm |

| 220mm×220mm | 6mm~30mm |

| 250mm×250mm | 6mm~30mm |

| 270mm×270mm | 6mm~30mm |

| 280mm×280mm | 6mm~30mm |

| 300mm×300mm | 8mm~30mm |

| 320mm×320mm | 8mm~30mm |

| 350mm×350mm | 8mm~30mm |

| 380mm×380mm | 8mm~30mm |

| 400mm×400mm | 8mm~30mm |

| 420mm×420mm | 10mm~30mm |

| 450mm×450mm | 10mm~30mm |

| 480mm×480mm | 10mm~30mm |

| 500mm×500mm | 10mm~30mm |

| 550mm×550mm | 10mm~40mm |

| 600mm×600mm | 10mm~40mm |

| 700mm×700mm | 10mm~40mm |

| 800mm×800mm | 10mm~50mm |

| 900mm×900mm | 10mm~50mm |

| 1000mm×1000mm | 10mm~50mm |

|

Rectangular steel pipes/tubes production sizes: Out diameter: 40*20mm ~ 300*200mm Wall thickness: 1.6mm ~ 16mm |

||||||

| SIZE mm | WEIGHT kg/m | EST. LBS. PER FT. | SIZE mm | WEIGHT kg/m | ||

| EST. LBS. PER FT. | ||||||

| 40 x 20 x 1.60 |

1.38 |

0.93 |

150 x 100 x 6.30 |

22.4 |

15.08 |

|

| 40 x 20 x 2.60 |

2.1 |

1.41 |

150 x 100 x 8.00 |

27.7 |

18.64 |

|

| 50 x 30 x 1.60 |

1.88 |

1.27 |

150 x 100 x 10.00 |

35.714 |

24.04 |

|

| 50 x 30 x 2.60 |

2.92 |

1.97 |

160 x 80 x 3.20 |

11.5 |

7.74 |

|

| 50 x 30 x 2.90 |

3.32 |

2.23 |

160 x 80 x 4.00 |

14.3 |

9.62 |

|

| 50 x 30 x 3.20 |

3.49 |

2.35 |

160 x 80 x 5.00 |

17.4 |

11.71 |

|

| 50 x 30 x 4.00 |

4.41 |

2.97 |

160 x 80 x 6.30 |

21.4 |

14.4 |

|

| 60 x 40 x 2.60 |

3.73 |

2.51 |

160 x 80 x 8.00 |

26.4 |

17.77 |

|

| 60 x 40 x 2.90 |

4.23 |

2.85 |

160 x 80 x 10.00 |

32.545 |

21.87 |

|

| 60 x 40 x 3.20 |

4.5 |

3.03 |

160 x 90 x 4.50 |

16.6 |

11.17 |

|

| 60 x 40 x 4.00 |

5.67 |

3.82 |

160 x 90 x 5.60 |

20.4 |

13.73 |

|

| 70 x 40 x 2.90 |

4.69 |

3.16 |

160 x 90 x 7.10 |

25.3 |

17.03 |

|

| 70 x 40 x 4.00 |

6.3 |

4.24 |

160 x 90 x 8.80 |

30.5 |

20.53 |

|

| 80 x 40 x 2.60 |

4.55 |

3.06 |

160 x 90 x 10.00 |

34.1 |

22.95 |

|

| 80 x 40 x 2.90 |

5.14 |

3.46 |

180 x 100 x 4.00 |

16.8 |

11.31 |

|

| 80 x 40 x 3.20 |

5.5 |

3.7 |

180 x 100 x 5.00 |

20.5 |

13.8 |

|

| 80 x 40 x 4.00 |

6.93 |

4.66 |

180 x 100 x 5.60 |

23 |

15.48 |

|

| 80 x 40 x 5.00 |

8.47 |

5.7 |

180 x 100 x 6.30 |

25.4 |

17.09 |

|

| 80 x 40 x 6.30 |

10.4 |

7 |

180 x 100 x 7.10 |

28.6 |

19.25 |

|

| 90 x 50 x 2.60 |

5.37 |

3.61 |

180 x 100 x 8.80 |

34.7 |

23.35 |

|

| 90 x 50 x 3.20 |

6.64 |

4.47 |

180 x 100 x 10.00 |

38.8 |

26.11 |

|

| 90 x 50 x 4.00 |

8.18 |

5.51 |

180 x 100 x 12.50 |

46.9 |

31.56 |

|

| 90 x 50 x 5.00 |

10 |

6.73 |

200 x 100 x 4.00 |

18 |

12.11 |

|

| 90 x 50 x 6.30 |

12.3 |

8.28 |

200 x 100 x 5.00 |

22.1 |

14.2 |

|

| 90 x 50 x 7.10 |

13.7 |

9.22 |

200 x 100 x 6.30 |

27.4 |

18.44 |

|

| 100 x 50 x 3.60 |

7.98 |

5.37 |

200 x 100 x 8.00 |

34 |

22.88 |

|

| 100 x 50 x 4.50 |

9.83 |

6.62 |

200 x 100 x 10.00 |

40.6 |

27.32 |

|

| 100 x 50 x 5.60 |

12 |

8.08 |

200 x 120 x 4.00 |

19.3 |

12.99 |

|

| 100 x 50 x 7.10 |

14.8 |

9.96 |

200 x 120 x 5.00 |

23.7 |

15.95 |

|

| 100 x 50 x 8.00 |

16.4 |

11.04 |

200 x 120 x 6.30 |

29.6 |

19.92 |

|

| 100 x 60 x 3.20 |

7.51 |

5.05 |

200 x 120 x 8.00 |

36.5 |

24.56 |

|

| 100 x 60 x 3.60 |

8.55 |

5.75 |

200 x 120 x 8.80 |

36.9 |

24.83 |

|

| 100 x 60 x 4.50 |

10.5 |

7.07 |

200 x 120 x 10.00 |

45.1 |

31.62 |

|

| 100 x 60 x 5.60 |

12.9 |

8.68 |

200 x 120 x 12.50 |

54.7 |

38.87 |

|

| 100 x 60 x 6.30 |

13.5 |

9.09 |

200 x 120 x 14.20 |

60.9 |

43.64 |

|

| 100 x 60 x 7.10 |

15.9 |

10.7 |

220 x 80 x 6.00 |

26.816 |

18.02 |

|

| 100 x 60 x 8.80 |

19.2 |

12.92 |

220 x 120 x 6.30 |

31.6 |

21.27 |

|

| 100 x 80 x 6.3 |

16.37 |

11.02 |

220 x 120 x 8.00 |

39.4 |

26.52 |

|

| 110 x 60 x 3.60 |

9.05 |

6.09 |

220 x 120 x 10.00 |

46.2 |

31.09 |

|

| 110 x 60 x 4.50 |

11.1 |

7.47 |

220 x 120 x 12.50 |

58.7 |

39.51 |

|

| 110 x 60 x 5.60 |

13.6 |

9.15 |

220 x 120 x 14.20 |

65.4 |

44.01 |

|

| 110 x 60 x 7.10 |

16.8 |

11.31 |

250 x 150 x 5.00 |

29.9 |

20.12 |

|

| 110 x 60 x 8.80 |

20.1 |

13.53 |

250 x 150 x 6.30 |

37.3 |

25.1 |

|

| 110 x 70 x 3.20 |

8.51 |

5.73 |

250 x 150 x 8.00 |

46.5 |

31.29 |

|

| 110 x 70 x 4.00 |

10.8 |

7.27 |

250 x 150 x 10.00 |

56.3 |

37.89 |

|

| 110 x 70 x 5.00 |

12.7 |

8.55 |

250 x 150 x 12.50 |

68.3 |

45.97 |

|

| 110 x 70 x 6.30 |

15.5 |

10.43 |

260 x 140 x 6.30 |

37.5 |

25.23 |

|

| 120 x 60 x 3.20 |

8.51 |

5.73 |

260 x 140 x 8.00 |

46.9 |

31.56 |

|

| 120 x 60 x 4.00 |

10.6 |

7.13 |

260 x 140 x 10.00 |

57.6 |

38.76 |

|

| 120 x 60 x 5.00 |

13 |

8.75 |

260 x 140 x 12.50 |

70.4 |

47.38 |

|

| 120 x 60 x 6.30 |

16.1 |

10.84 |

260 x 140 x 14.20 |

78.8 |

53.03 |

|

| 120 x 60 x 7.10 |

17.9 |

12.05 |

260 x 180 x 6.30 |

41.5 |

27.93 |

|

| 120 x 60 x 8.80 |

21.5 |

14.47 |

260 x 180 x 8.00 |

52 |

35 |

|

| 120 x 80 x 3.20 |

12.1 |

8.14 |

260 x 180 x 10.00 |

63.9 |

43 |

|

| 120 x 80 x 6.30 |

17.5 |

11.78 |

260 x 180 x 12.50 |

78.3 |

52.7 |

|

| 140 x 70 x 4.00 |

12.5 |

8.41 |

260 x 180 x 14.20 |

87.7 |

59.02 |

|

| 140 x 70 x 5.00 |

15.4 |

10.36 |

300 x 100 x 5.00 |

30.268 |

20.34 |

|

| 140 x 70 x 6.30 |

19 |

12.79 |

300 x 100 x 8.00 |

47.679 |

32.04 |

|

| 140 x 70 x 7.10 |

21.2 |

14.27 |

300 x 100 x 10.00 |

58.979 |

39.63 |

|

| 140 x 70 x 8.80 |

25.6 |

17.23 |

300 x 200 x 5.00 |

37.8 |

25.44 |

|

| 140 x 80 x 3.20 |

10.5 |

7.07 |

300 x 200 x 6.30 |

47.1 |

31.7 |

|

| 140 x 80 x 4.00 |

13.1 |

8.82 |

300 x 200 x 8.00 |

59.1 |

39.77 |

|

| 140 x 80 x 5.00 |

16.2 |

10.9 |

300 x 200 x 10.00 |

72 |

48.46 |

|

| 140 x 80 x 6.30 |

20 |

13.46 |

300 x 200 x 12.00 |

88 |

59.22 |

|

| 140 x 80 x 8.00 |

24.8 |

16.69 |

||||

| 140 x 80 x 10.00 |

30.2 |

20.32 |

||||

| 150 x 100 x 3.20 |

12 |

8.08 |

||||

| 150 x 100 x 4.00 |

14.9 |

10.03 |

||||

Standard & Grade

ASTM A500 Grade B, ASTM A513 (1020-1026), ASTM A36 (A36), EN 10210:S235, S355, S235JRH, S355J2H, S355NH, EN 10219:S235, S355, S235JRH, S275J0H, S275J2H, S355J0H, S355J2H.

| Chemical composition of square a& rectangular pipes material | |||||

| Grade | element | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

| EN10027/1 | C% max (Norminal W.T.(mm) | Si% max | Mn% max | P% max | S% max | N% max | |

| and IC 10 | ≤ 40 | ||||||

| S235JRH | 0.17 | 0.2 | - | 1.4 | 0.045 | 0.045 | 0.009 |

| S275JOH | 0.2 | 0.22 | - | 1.5 | 0.04 | 0.04 | 0.009 |

| S275J2H | 0.2 | 0.22 | - | 1.5 | 0.035 | 0.035 | - |

| S355JOH | 0.22 | 0.22 | 0.55 | 1.6 | 0.04 | 0.04 | 0.009 |

| S355J2H | 0.22 | 0.22 | 0.55 | 1.6 | 0.035 | 0.035 | - |

| Mechanical properties of material | |||

| Grade | Yield Strength | Tensile Strength | Elongation |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norm | Yield Strength | Tensile Strength | Min.elogation | Min.percent properties | ||||||||

| Acc.to EN10027/1

and IC 10 |

Acc.to EN10027/2 | Norminal W.T.mm | Norminal W.T.mm | Longit. | Cross | Test temperature°C | Average min.impact value | |||||

| ≤16 | >6 | >40 | <3 | ≤3≤65 | Norminal W.T.mm | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

| Equivalent specfications | ||||

| EN 10210-1 | NF A 49501 NF A 35501 | DIN 17100 DIN 17123/4/5 | BS 4360 | UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | – | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | – | St E 285 N | – | – |

| S275NLH | – | TSt E 285 N | 43 EE | – |

| S355NH | E 355 R | St E 355 N | – | – |

| S355NLH | – | TSt E 355 N | 50 EE | – |

| S460NH | E 460 R | St E 460 N | – | – |

| S460NLH | – | TSt E 460 N | 55 EE | – |

Quality Control

Raw Material Checking, Chemical Analysis, Mechanical Test, Visual Inspection, Tension Test, Dimension Check, Bend Test , Flattening Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test…..

Marking, Painting before delivery.

Packing & Shipping

The packaging method for steel pipes involves cleaning, grouping, wrapping, bundling, securing, labeling, palletizing (if necessary), containerization, stowing, sealing, transportation, and unpacking. Different kinds of steel pipes and fittings with different packing methods. This comprehensive process ensures that the steel pipes shipping and arrive at their destination in optimal condition, ready for their intended use.

Usage & Application

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide.

The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...